|

Advertisement / Annons: |

Project:

|

Contents:

Related projects:

Note: |

11: Redesign of mount head detailsAt page 13 I started with the lower part of the mount, the tripod and modified it to get it both lower, lighter and more stiff. Now I take a look at the upper part. The dovetail I have now is something that I use when setting up a prototype, very stable and flexible. But it weight a lot, it is big and it place the mass center of the cameras and lenses far away from the RA axis center. If I can make it more compact, closer to RA center it will be more wind resistant and have a lower weight too. That have the positive effect that I could use a counter balance with less weight. HEQ5 mount head:

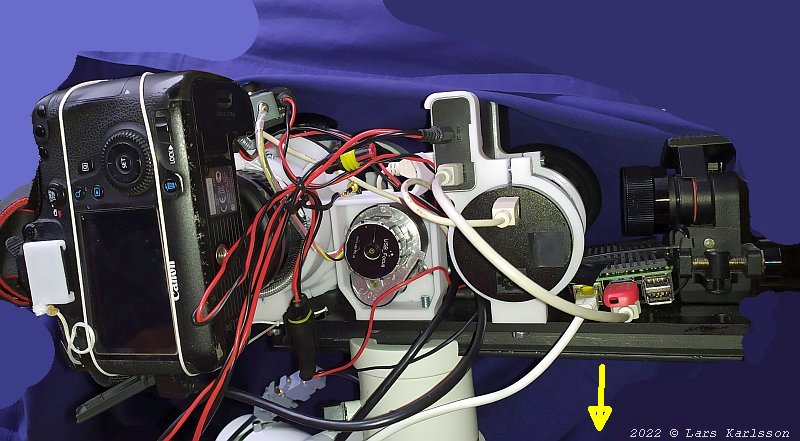

This is how it looks with the old setup. I want to make the dovetail to sit lower and closer to the RA axis center. The weight of all this: camera, lenses, dovetail, focuser motor, Raspberry, USB HUB and DC/DC converter weighs 5.4 kg. How much can I reduce this weight ? Combined lens and motor focuser bracket:

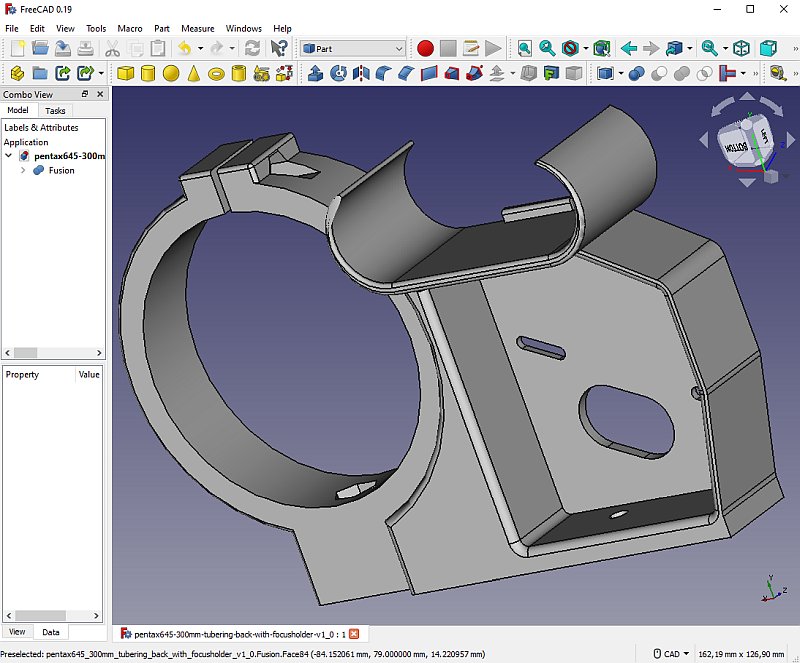

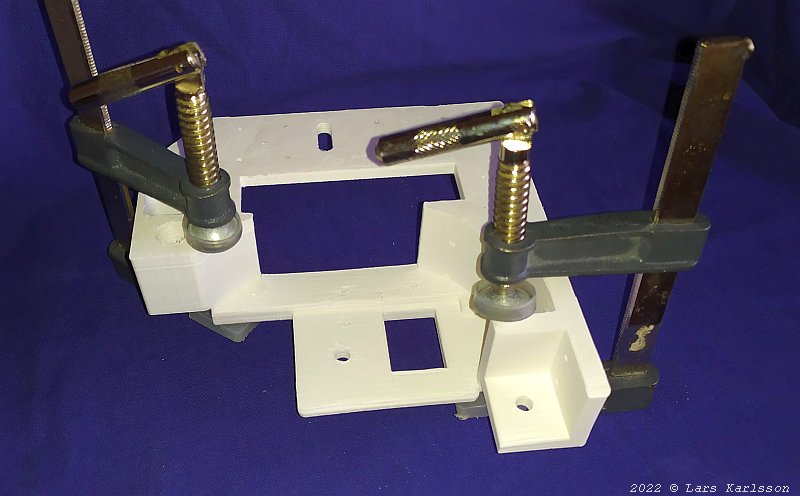

The first thing I have to do is to make a new motor focuser bracket. Earlier it was a stand alone construction, I could notice some weakness in it and that cause some flex. Flex and backlash isn't good for the auto focus system. Now I joined it together with the lens holder bracket. At the same time I corrected some mistakes I did in the earlier design.

Here you can see clearly how the honey comb structure strengthen the focus motor bracket. Rather complicated geometry to get the focus motor in correct places with correct tension of timing belt in its middle position, the angle must also be correct and the axial position.

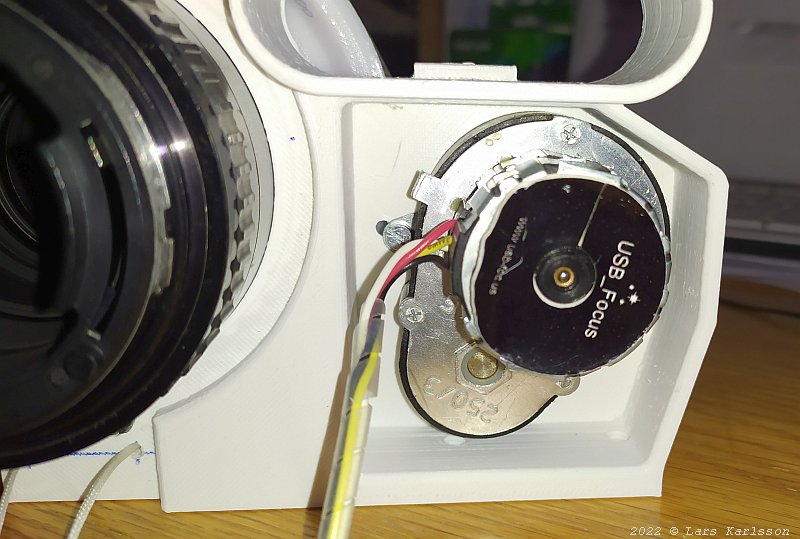

After I started to use glue stick on the printer bed the printed result improved a lot. Now it's ready to move over the lens and focus motor from old bracket to this new bracket.

When assembling the new bracket I added an extra screw to the spring that hold the aperture with force to be fully open. Not good to do this after the bracket is 3D-Printed, it's impossible to drill and thread, I used super glue to hold the screw in place. I also added two extra holes for the string that force the bayonets to be tight against each other.

More space around the stepper motor, now it's much easier to adjust the tension of the timing belt and it's centered around the middle position.

The nuts slides in a rail, when tightening the screw the nuts doesn't rotate now. As usually, I need to design three versions until I'm satisfied. Much more stable now when the two brackets are joined together as one unit. The drawback is that I need a new focus bracket for each lens / telescope setup. Low profile dovetail:

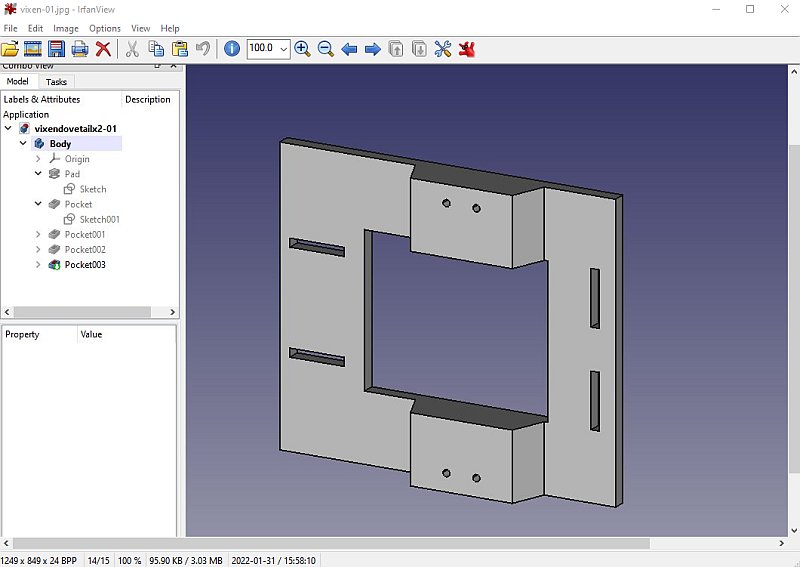

First I thought I could 3D-Print a new dovetail or a hybrid between plastic and aluminum, this is how my first idea looks like. The central opening let it slide over the DEC axis and then it get closer to the center of the RA axis center. Across the center opening a normal short dovetail will be screwed on. On the left side the guide camera and on the right side the main camera. The problem was that my 3D-Printer could not print a large object like this, not even if I divided it in half. The printer bed has a diameter of 230 mm and the maximum height is 280 mm. Another problem is that a flat design like this doesn't have the needed strength.

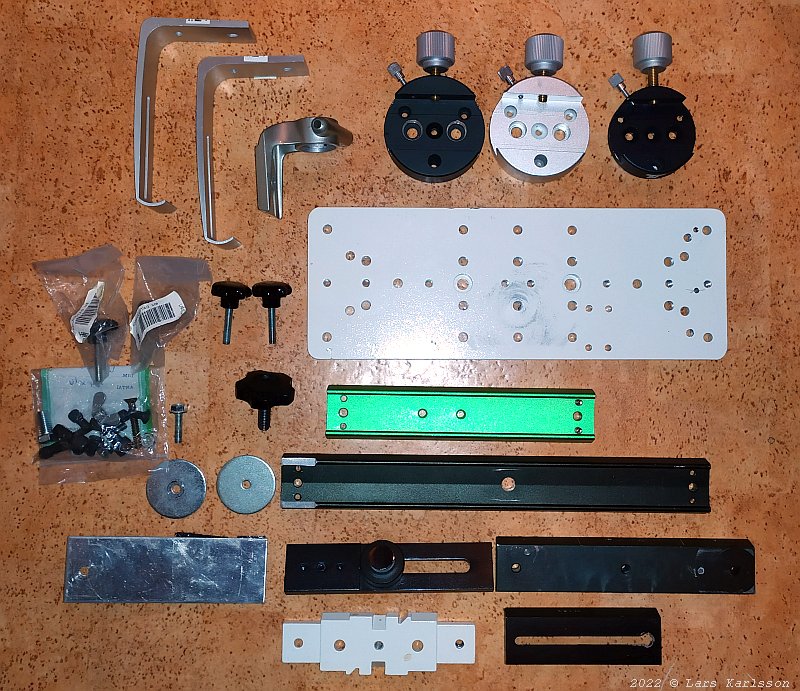

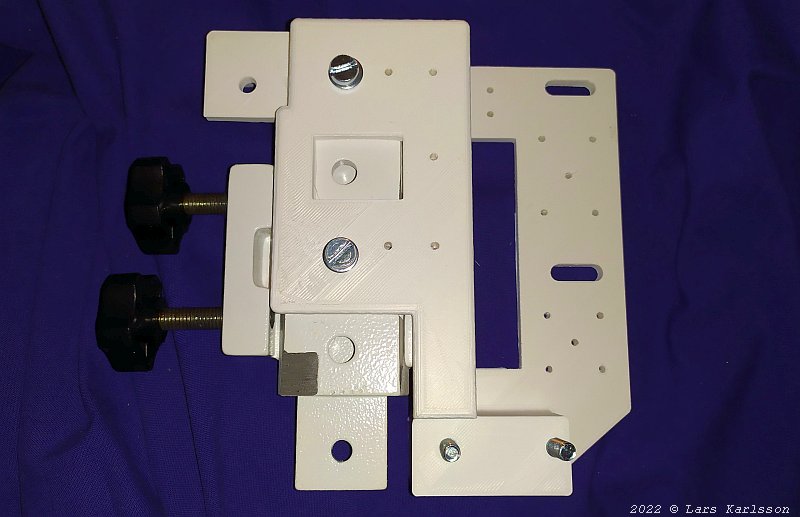

Today I got some used parts I bought, together with other brackets I have in my boxes I can use them to this setup. The two upper left brackets come from IKEA. The big white plate in middle could be perfect, I just have to mill up a rectangular hole in the middle. But I decided to keep it for some other needs in the future.

I tried this first. A short dovetail with two clamps at each end. The clamps occupy too much space and I cant move the dovetail when I need to balance it. This was a no good solution.

Maybe something like this is a better idea, I need some extra space on the left side for the lock screws to the dovetail. But better if I can find a 200 x 200 x 3 mm aluminum plate. But I don't have the tools to make a rectangular hole in it and bend it. Now I have something to think about the coming days. When I design this bracket I try to have it back heavy, then I can push the lenses forward to get it in balance. With that I maybe don't need to do meridian flip when passing the meridian. Later I found this to be very difficult, better with a fork mount and as a bonus there is no need of balance weights, see some thoughts here. But at least I can delay the meridian flip by two hours. Bracket for Pentax 645 300 mm and focuser:

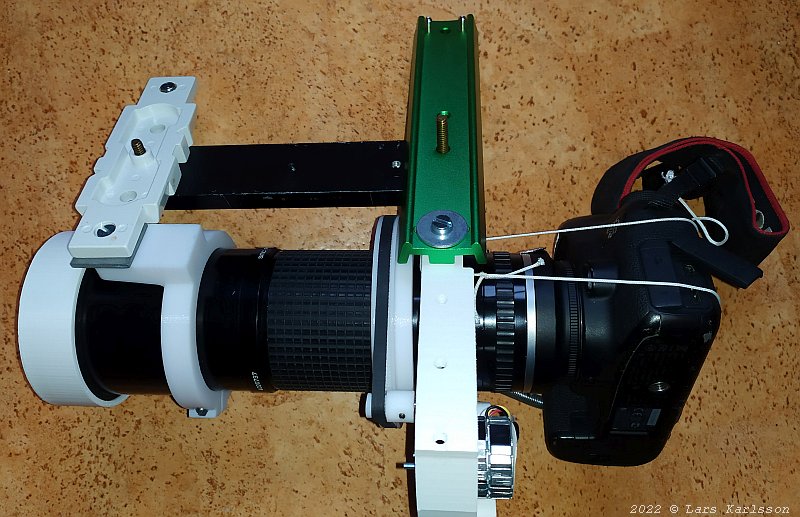

Now when the focus bracket is finished I can install it on the dovetails I have. Just for a test to check if it fits.

With a position near the center of the DEC axis. On the left side the guide camera will be installed. It must clear the lock screws and also balance the much heavier main camera with its Pentax 645 300 mm lens.

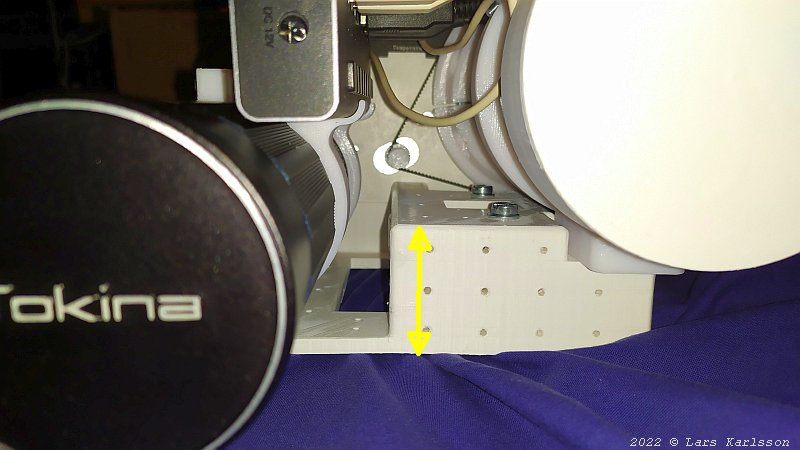

The main lens position relative the RA axis is 30 mm closer to the center of its axis compare with the earlier installation. If it's possible I want to have it even closer. Then I need it to go outward 20 mm from the DEC axis to clear the head. The lowest I can have it is 70 mm compare to earlier setup. The big advantage of this is that I can reduce the mass of the counter weight a lot. But also a more compact setup which is convenient for a travel setup. As it's now it's very back heavy, the lens needs to be moved 45 mm to the the front (left in image). Then another problem occurs, the top end of the DEC axis protrude and collide with the timing gear. I have to move (upward) it 25 mm more or 45 mm total outward from the DEC axis. That will be not good to add so much extra balance mass for the transversal balance on the guide camera side when the goal is to built a low weight setup.

A look from below, the green dovetail will later be replaced with some own design and 3D-Printed.

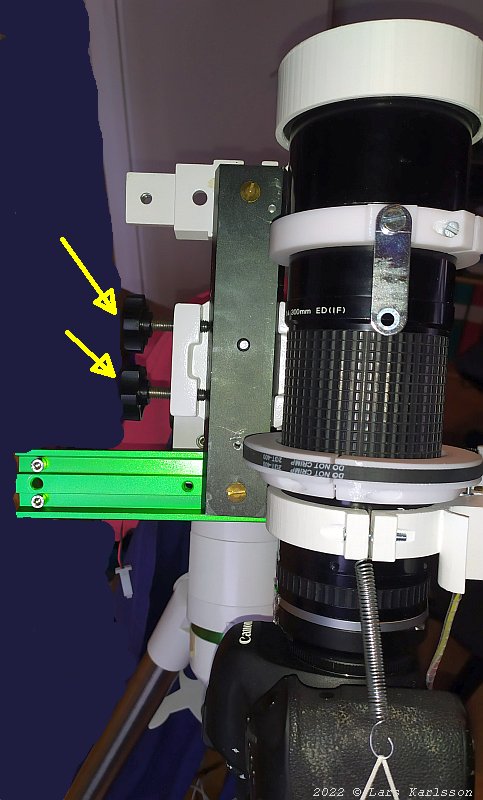

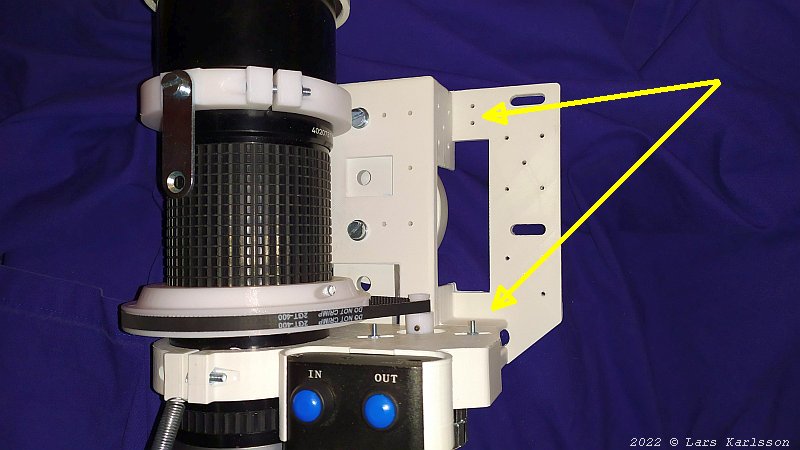

At last I decided to use the smallest dovetail I had, it's not a real Vixen standard and I had to nail down the protruding parts. The angle most right is for clearance for the timing belt gear. With this I get the most compact solution. I have also rearranged the devices that attaches to the dovetail.

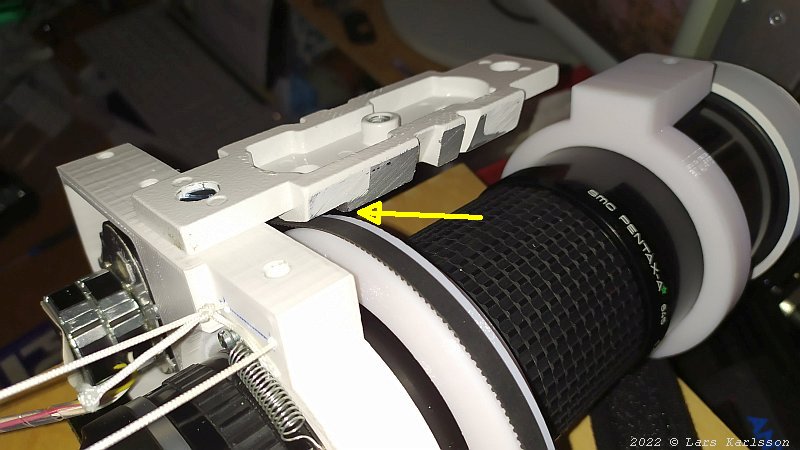

At the arrow, the cut in the dovetail to let the timing belt gear to rotate free. I have to design a new front bracket, mirror it. The lens is now offset by 35 mm sideways, the guide camera will counter balance that and more. I now place the Pentax lens above the lock screws for the dovetail. Guide system bracket:

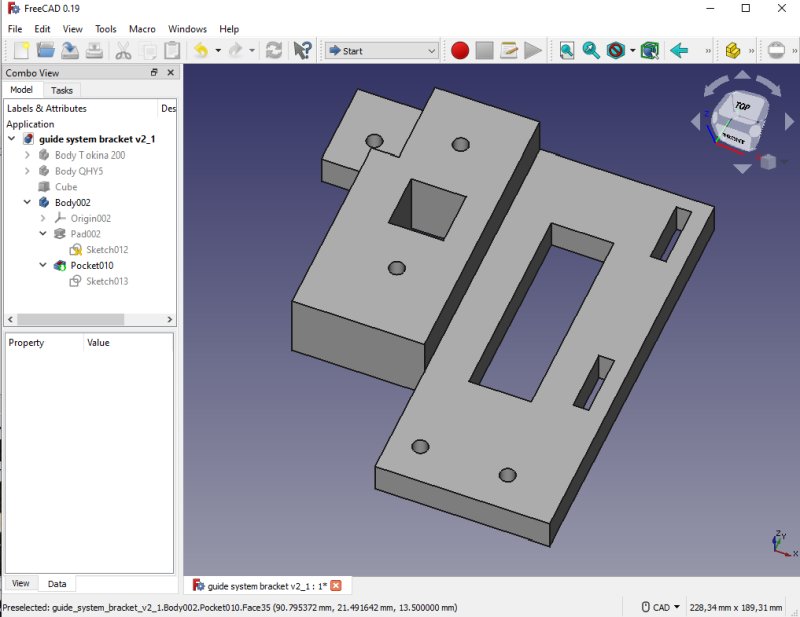

The bracket for the guide camera and its lens will be placed on top of the Pentax lens bracket, the white dovetail. It's designed in four different levels to make most of the space and move the mass closer to the center of RA axis. If needed I can counter balance the guide camera / lens in sideway direction at the counter balance with an offset weight. The slits most right is for counter balance the guide camera / lens along the optical axis, a complement to the dovetail adjustment.

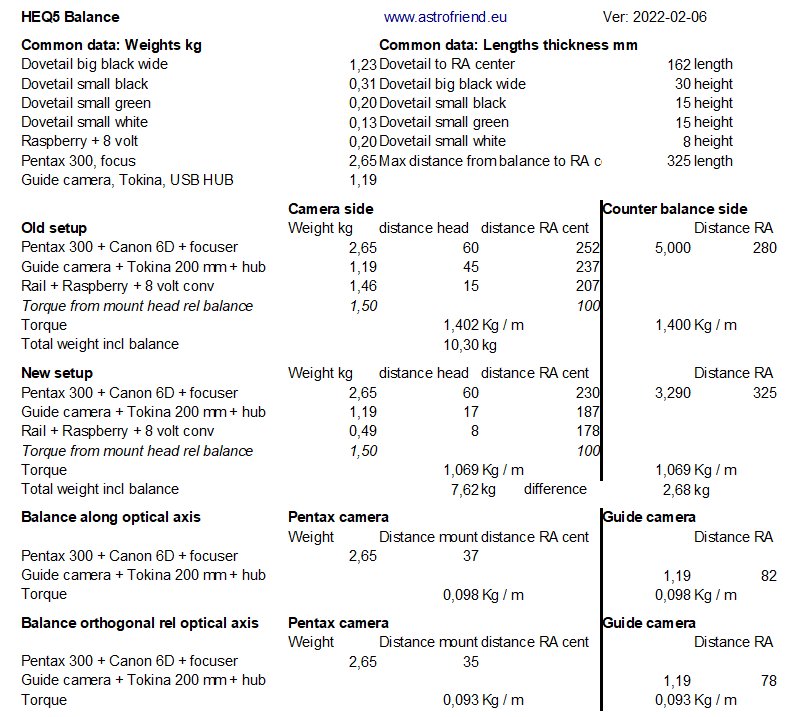

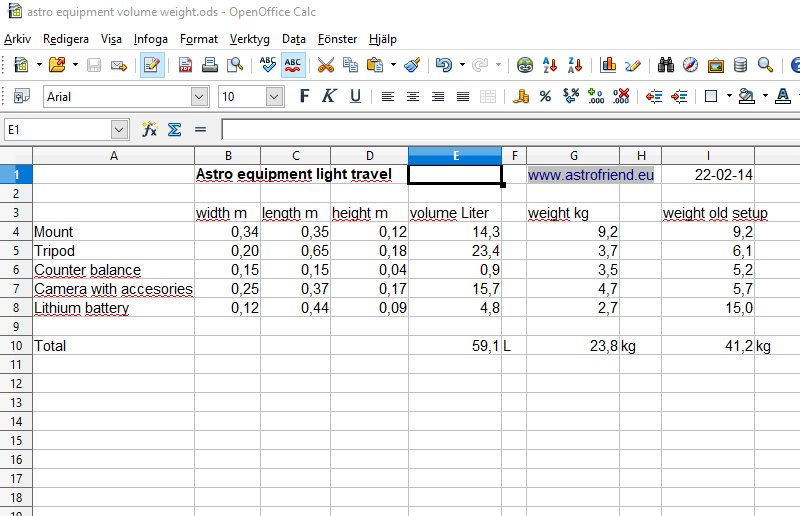

To find the weight balance in three dimension I set up a Excel sheet. It give me the information that I save 2.7 kg if I do this and also reduce the counter balance weight from 5 kg to 3.3 kg.

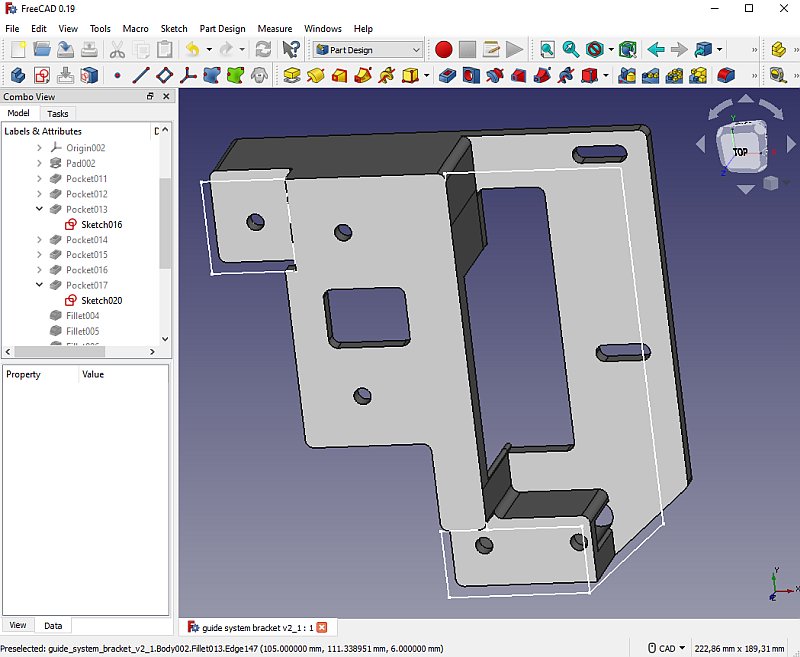

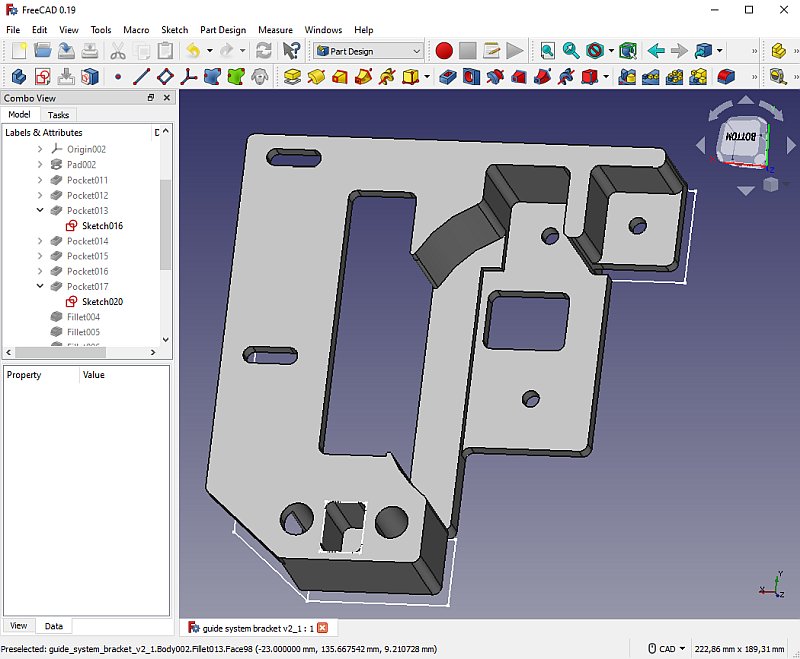

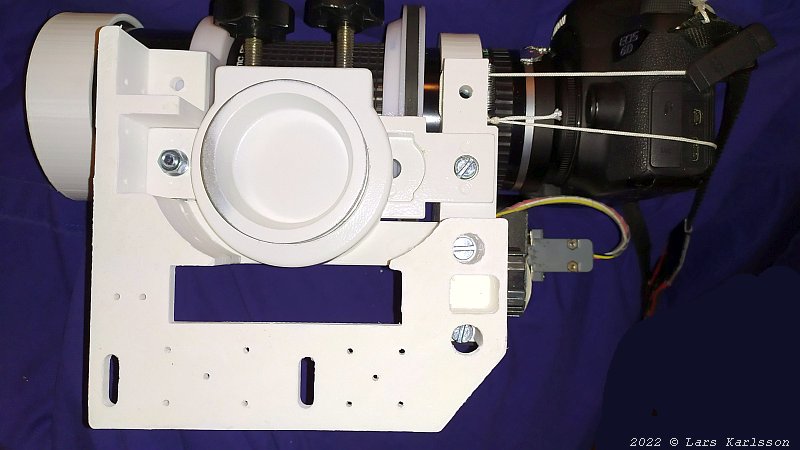

Many hours later and many changes. To the left, place for Pentax 645 300 mm lens and camera. To the right, place for the guide camera and lens. I changed the directions of the slits for the guide camera, now it adjust the sideway direction of the optical axis' balance. At the middle, where it attaches to the dovetail and DEC axis.

A view from below. Lot of protruding details from the mount that must be openings for. The 3D-Printer need 10 hours to print this bracket. I print it with ABS Pro filament, but there is always the opportunity to hand it over to a workshop that can 3D-Print it in aluminum instead. How big chance is there that it will be correct the first time ? 0%, normally I need three versions until I come close to what my intentions are.

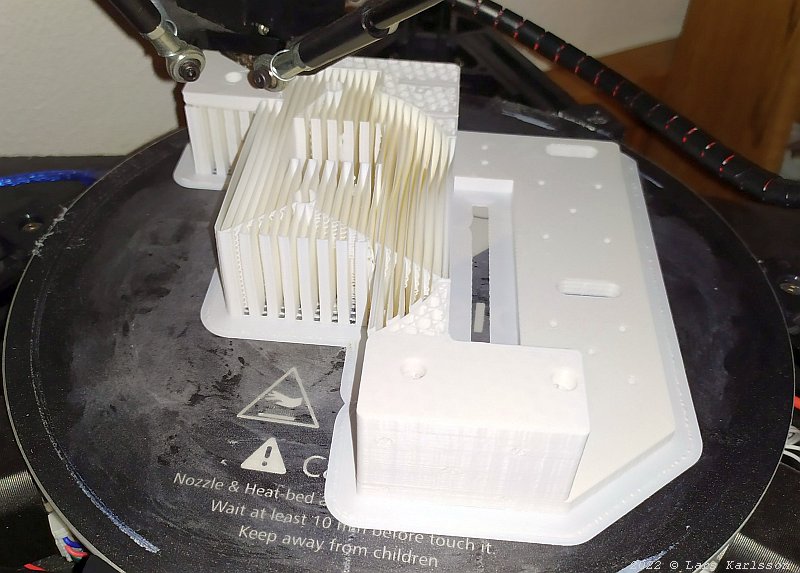

The 3D-Printer has started and has now done 80% of the job. You can clearly see how it build the support for the higher levels.

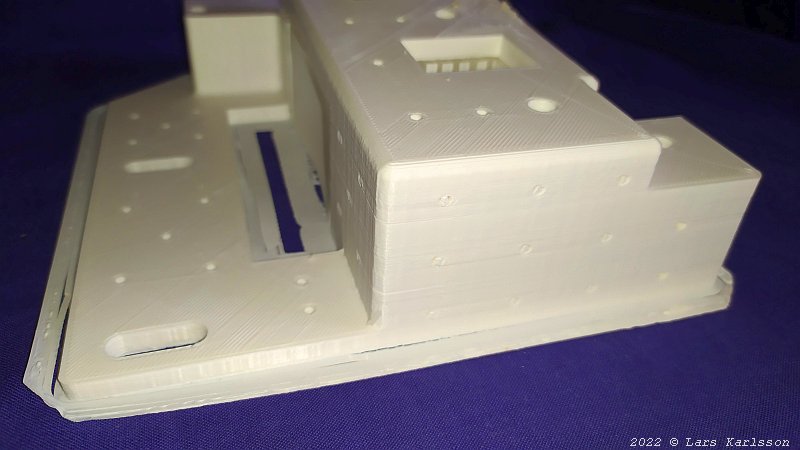

Out from the 3D-printer, I can directly see some problems. Layers that are not stuck to each other and warping problems.

The upper platforms has warped because it didn't get stuck enough to the lower laying layers.

It's relative easy to glue this plastic with super glue. I hope I can get it good enough to do some test. In a later version I will let a bolt go all the way through to strength it up.

I added a lot of 2.4 mm holes, I can later thread these for M3 screws and attach other devises. If it's not prepared for this before 3D-Printing it's impossible to drill and thread the holes afterwards.

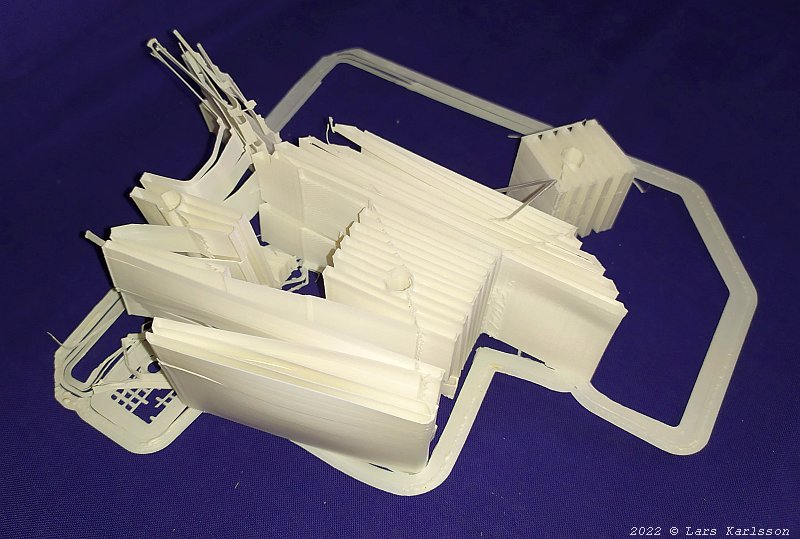

The support after it has been breaking away from the main structure, a lot of waste of material.

Glue the layers together with super glue. You can read here: Wind shield, how I try to improve the 3D-Printing process with the ABS Pro filament.

Now the exiting part, assembling it together. The dovetail to the left has its middle hole threaded for 1/4", I re-threaded it for M6, almost the same.

It almost fit perfect, just one level that was in wrong position along Z-axis, I filled it out with washers.

From below, the top end of the mount, the circular part. It can be adjusted 25 mm when balancing DEC axis, it's not much but it's special designed for this low weight setup.

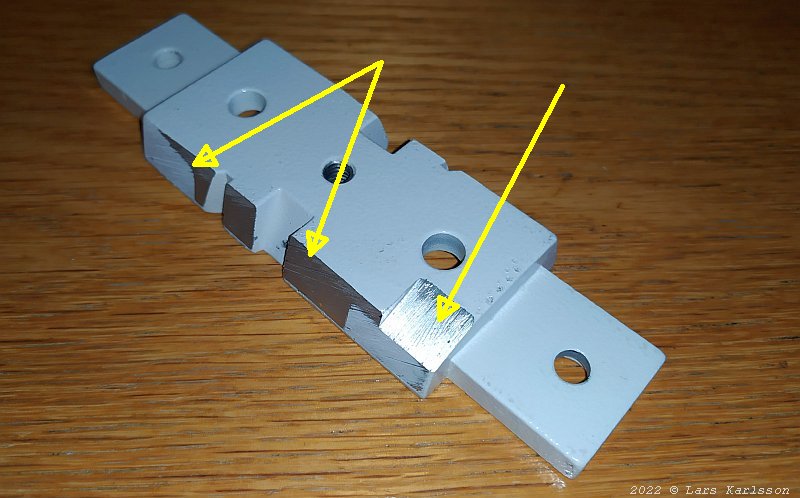

Where the arrow points are weak areas, it flex here and I have to reinforce it in next version.

With the guide camera and its lens installed. They are at the position when it's in balance, no more extra weights needed. The weight is now 4.6 kg, compare to earlier when it was 5.4 kg.

The ABS Pro filament is difficult to work with, one more crack has appeared. Otherwise it looks good, there are enough space around the different devices.

Here I will drill a hole and install a bolt that hold together the bracket as an extra safety, next version will have it implemented already from the beginning. At this flat surface I will install the temperature sensor. M3 holes are already there for the screw. The guide camera and lens now is placed 66 mm closer to the RA axis center. It will reduce the torque and then counter balance weight.

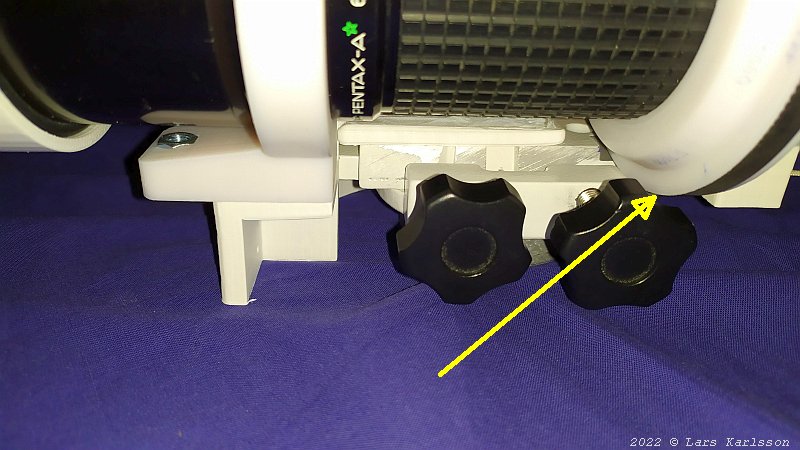

The right bolt that lock the dovetail needs to be longer. The threads length are now 37 mm, a length of about 50 mm is better, otherwise it hit the timing belt wheel. The complete system here fits in a box with dimension: 37 x 24 x 17 cm and weighs 4.6 kg. Very satisfied with this, I just have to do some enforcement at critical places. Stabilizer bar and handle:

One of the reinforcement I have to do is to get rid of the flex between main lens and the guider lens. Looking what I have in my boxes and found a book shelf bracket from IKEA. Cut, drill, bent and nail it to fit.

With this bar it's stable as a rock, at the same time I got a handle which is good to have. Out in the dark and cold it's not so easy to setup the equipment. The bar is made of iron and the magnet on the GPS can stuck to this bar.

Later when I know if this bar works as supposed I will 3D-Print a distance to the screw at left. If I include all devices attached to this the total weight is now 4.7 kg, 1 kg lees then the earlier setup. I can also reduce the counter balance weight with 1.7 kg and the tripod by 2.4 kg. Totally 5 kg less weight, a big difference when you have to carry all these. Don't forget the 15 kg weight saving of the battery. Assembling it together:

At last I can install the head on the now much lower tripod. Much lighter now, earlier the 5.2 kg counter balance was at the outer end, now it's moved in 72 mm. I can later replace this counter balance of 5.2 kg with one of 3 kg. I also could adjust the balance along the two other axis. It can pass the meridian by at least 30 degree or 2 hours without hit anything. The RA axis can rotate +/- 120 degrees without anything hit the mount. This is just the prototype, but I could use it and get experience until I design ver. 2.

A coarse estimate of the volume of the equipment. I got it to 59 L, maybe a 90 L box can hold everything, but better to divide it in two boxes with the camera head in a separate box.

|

|