|

Advertisement / Annons: |

Project:

|

Contents:

Related projects:

Note: |

10: Making the tripod to a low riderThe main reason when I bought this Sky Watcher HEQ5 mount was to get something smaller, lighter and easier to transport compare to my EQ6 mount. When living in a high light polluted area it's important to have the opportunity to bring the equipment out to a dark place. Now when I have got the function of the astroserver to work pretty well I take a look at how to reduce the volume and weight of the equipment. When never doing any visual observation there is no need to have a high tripod to the mount. If I replace the long legs with some shorter it will take much less space in the trunk of the car and it reduce the weight. HEQ5 tripod:

The height of the tripod up to the base where the mount is placed is 0.85 meter. I plan to reduce the height to about 0.5 meter. That's the lowest I can have the tripod legs without spread them outwards to not have it too unstable. The tubes are made of stainless steel and they have the diameter of 44.5 mm (1 3/4"). In Sweden most tubes has the diameter in the Metric system, 45 mm. Now this project went complicated already in the beginning. But I found some stainless steel tubes and ordered them. They will arrive next week, you will be very surprised over what I found. Tripod leg foot:

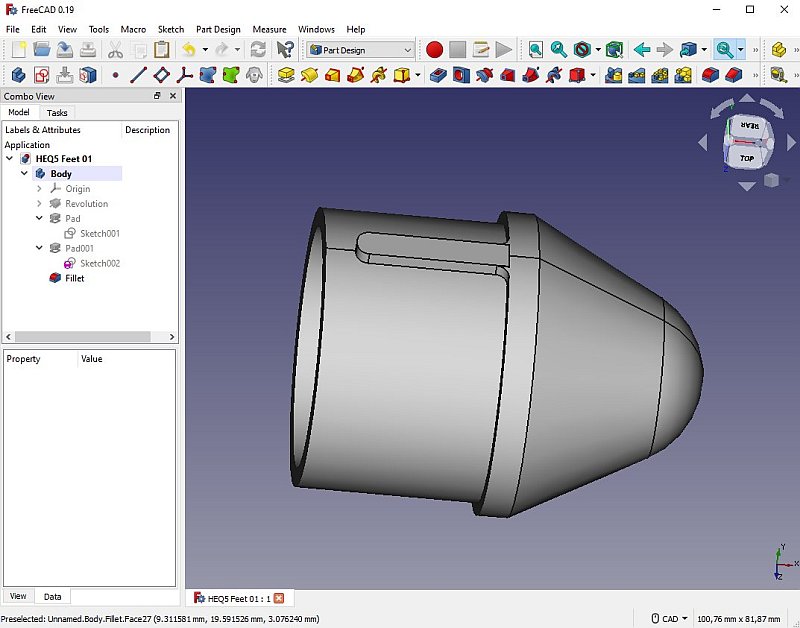

Meanwhile I waiting for the new stainless tubes to arrive I took a look how to construct the end feet of the legs, the end that stands on the ground. I could construct it to have them adjustable in height by a screw, but that make it more complicated and it will not be as stable as without the screw. This end is down in the dirt and that can cause problem with the threads and the screw will rust if it's not made of stainless steel. It also add some extra weight. I did this simple design in 3D-CAD, if I later decide to go for an adjustable screw I can design that too in 3D-CAD and 3D-Print it.

The new foot 3D-printed. It's made from ABS-Pro filament and I increased the nozzle temperature to 240 degrees Celsius to get the layers better stuck to each other.

Foot installed on the new leg, it's stable and looks good. New tripod legs arrive:

A package arrived today with my new shorter legs. Unpack it and take a look if they are of correct size. And yes it's correct, 1 3/4" and not the metric 45 mm. These tubes have an outside diameter of about 44.5 mm, the thickness of the tube is 1.5 mm. Can you guess where I found those stainless steel tubes ? It's from an exhaust system ! I only paid 37 Euro for all three of them and they are polished too.

Compare the lengths of the new ones relative the original.

Without the top bracket the original legs weighs 1.57 kg each, the new short leg with a plastic foot weighs 0.775 kg. That's a weight saving of 2.4 kg and I get a lot more compact equipment and have a relative advanced mount.

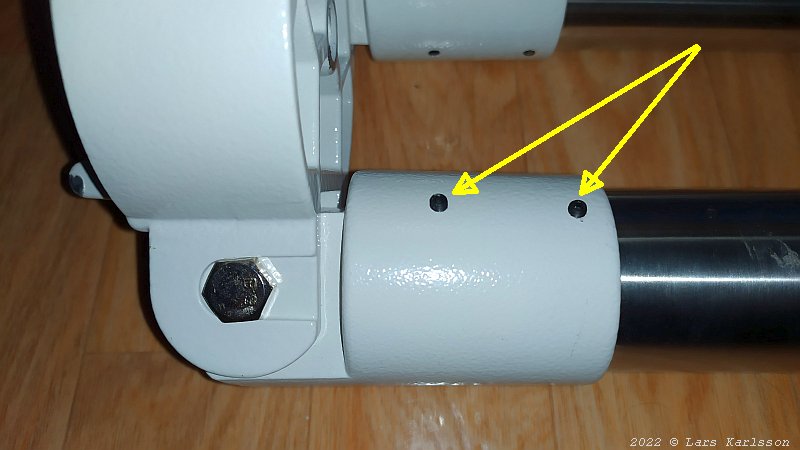

Each tube is hold in place with four 2 mm grub hex socket screws. Is it just to loosen them and replace the tube, or ?

No, they are stuck as if they were welded together. I tried to heat the casted aluminum head and cool the tube, no success yet. I think they must have glued them together, heat can get the glue to separate, but how hot ? I already tested with boiling water.

Note 1:

Note 2: I found a thread at the Cloudy Nights forum where they discuss this problem: Maybe I didn't let it have time enough to melt the glue, I do another try tomorrow. I repeated the boiling process and this time I let it be boiled for much longer time. At last it get loose but it wasn't easy. I had to boil it several times because it cooled off during my attempt to remove it. I put a screw driver in the hole and rotate back and forth and push it away from the tube. Beware, it's hot, have some protecting gloves for the heat !

And then, I just install the hinge bracket on the new tube ? Of course not, it didn't fit exact. The tube has an small edge, maybe from the cutting of the tube. And it is not perfect round either, I was the responsible for this, squeezed it too hard in the bench vise. It varies from 44 to 45 mm but easy to correct in the bench vise. The thickness of the old tubes are 1.5 mm, exactly as the new legs thickness.

First I have to clean the hinge bracket from old paint and glue.

Then I have to nail down the edge of the new tube. I also squeezed the tube with the bench vise to get it perfectly round again.

The two and half legs tripod. Now I'm asking myself, should I proceed with the two other two legs or stop here and reinstall the old leg ? Let me think about it, this is a many hours work and I don't want to destroy the mount. The earlier owner maybe will cry now when he see what I have done. But without a working travel setup, no fun. An attempting alternative, why not 3D-Print a new head. Not with moveable legs, a fixed angle. Then I can have a bigger angle and spread the legs more to have it more stable. A squeeze lock mechanism for the legs in the upper end so it's easy to remove and install them. The filament I'm working with now, the ABS Pro should be strong but I always get problems with it. But other parts I printed earlier in PLA is relative strong but the carbon fiber filament maybe the best filament for this purpose. Some overview of the dimensions, the head will get a diameter of 250 mm at least, more than my 3D-Printer can handle. Not the first time I found that I need a bigger 3D-Printer. A couple of days later, after I collected some mental strength I started with the two other legs. This time it was much easier, I have got some experience now. What's left now is to mount the hinge brackets on the new tubes. I must also replace all the hex socket screws, all of them got worn, too soft material.

It was not very difficult to insert the new short tubes. Just carefully remove old paint and glue. Test to insert it a couple of mm. If it feels okay, put some grease on the contact surfaces, very important. If you don't do that the tube can be stuck half way inn.

Next is to mount the legs to the mount plate.

First I tried to keep the old Teflon shims, I found it almost impossible to get them in correct place. Must find something else to replace them with. The shims is 0.2 mm thick with one shim at each side on two of the legs, the last only had one shim..

I used this plastic band with correct thickness. Wrap it around to make it easier to install.

Cut a hole in the shim with a drill.

Finished, the height up to the platform is 0.52 m, 0.33 m lower than it was originally.

With the HEQ5 head in place, this feels very good. So much easier to pack this in the trunk of the car when driving out to dark places. The battery and the Pad is missing here, add less than 3 kg. The camera package add 4.7 kg. Tripod leg wedge:

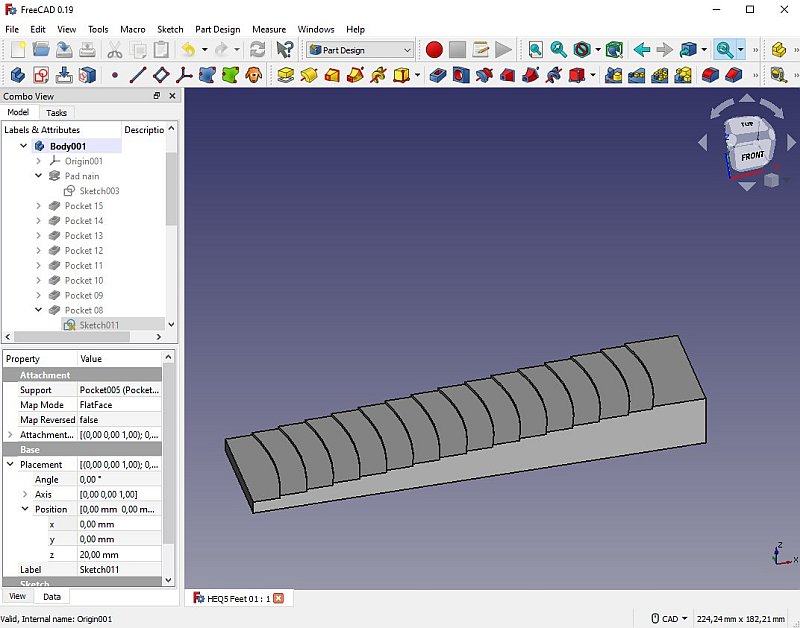

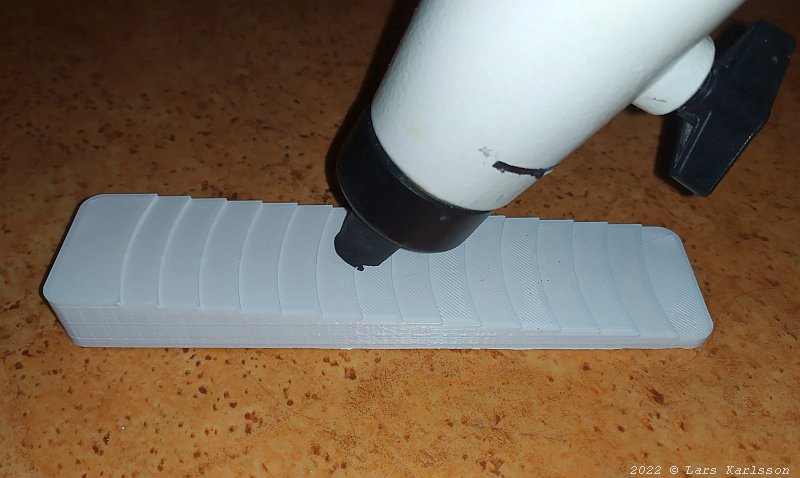

When designing the foot of the leg I also designed a wedge that I can put under the foot and have it adjustable in height. It's made like a stair case and has 15 levels with one mm step size. The overall size is 40 x 170 x 20 mm. If it's not enough I can increase the steps from one to two mm. It's a wonderful world we live in today with 3D-printers.

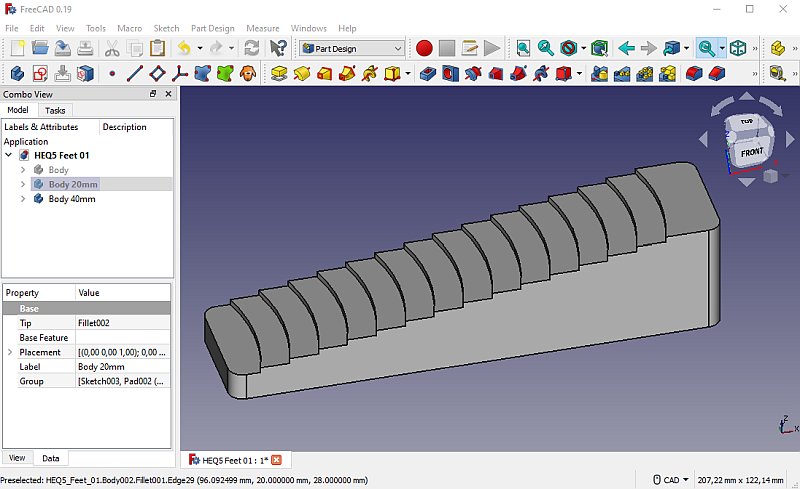

The second designing of a wedge. Even this has 15 levels but with two mm step size. The overall size is 40 x 170 x 40 mm.

It's plastic, but feels very stiff. I have to glue some rubber on the bottom side to not have it slide against the ground.

|

|