3, Installing the top limit switches and the top frame:

Mounting the top limit switches and the top frame:

Now it's time to move to the upper part.

Top limit switches and top frame.

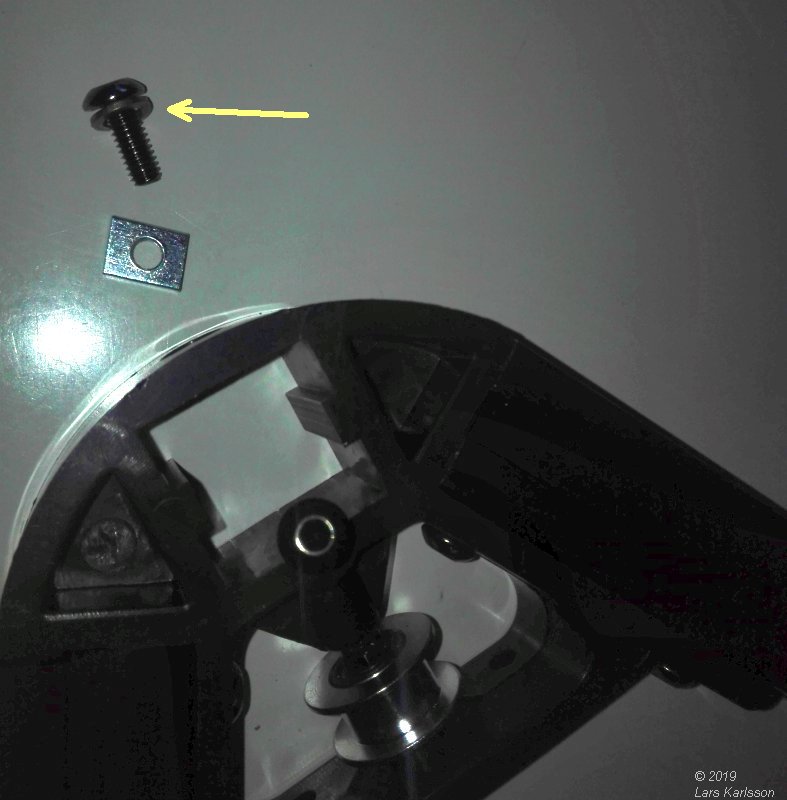

The plastic bag has a number that indentify it, very convinient.

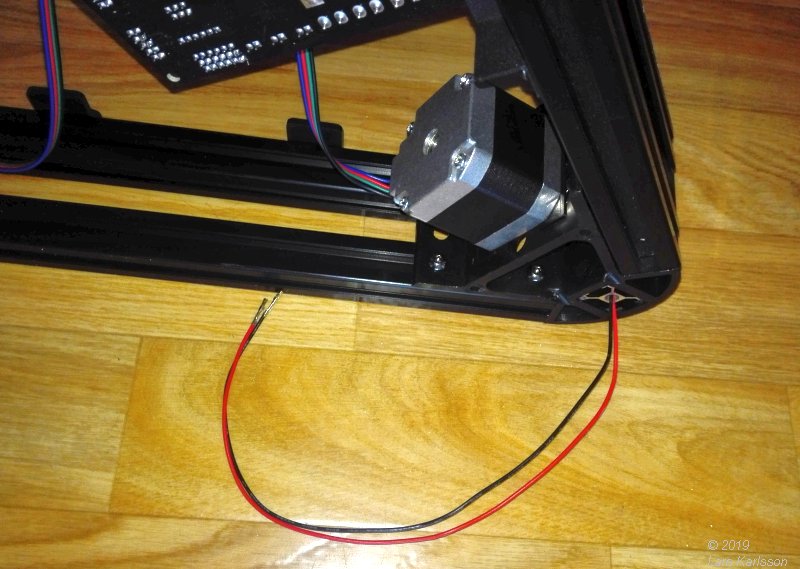

The

cables from the switches run through the pillars, do not get any bent on the cables

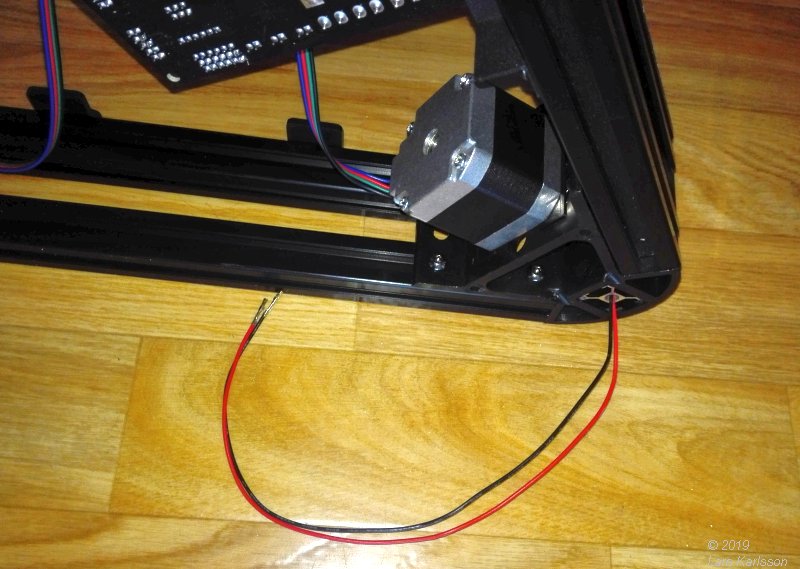

The cable come through at the bottom, there is holes prepared to let the cables connect to the pcb board.

I mounted the switches in the same direction on all pillars to have it symmetric, maybe good.

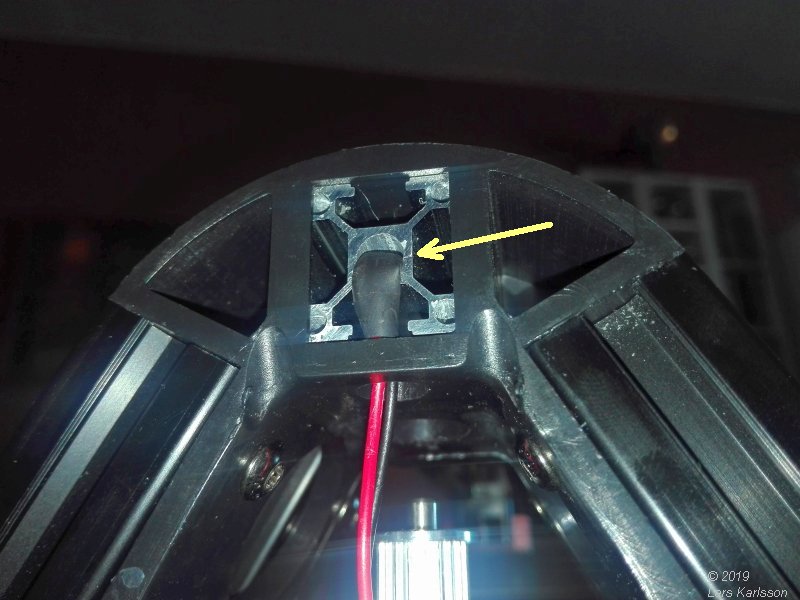

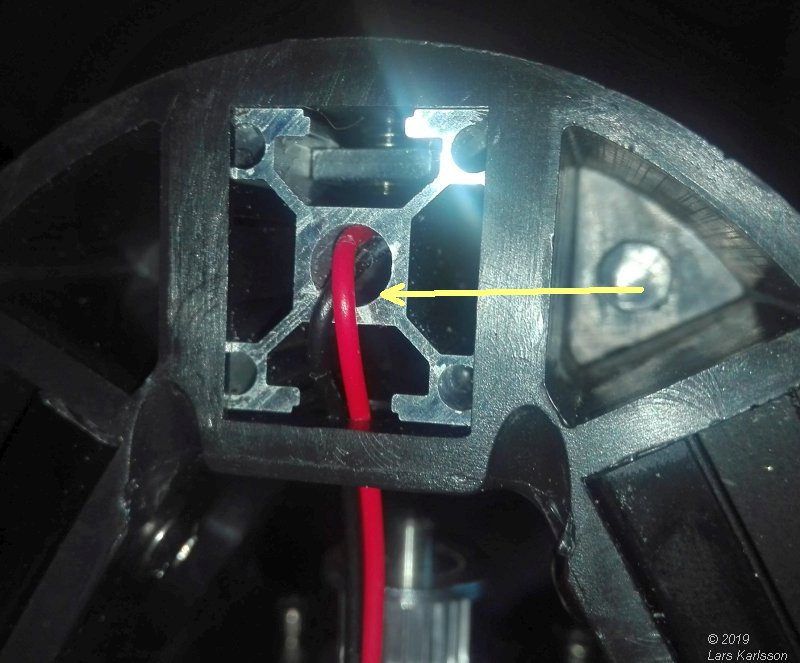

This didn't look nice to me. A very sharp edge at the pillar that can cut through the cable.

Looking in my boxes what I have laying around to fix this. Found plastic tubes that I could use. Cut six 20 mm tubes.

This is the top frame where the switches are located.

Put on the protection tube.

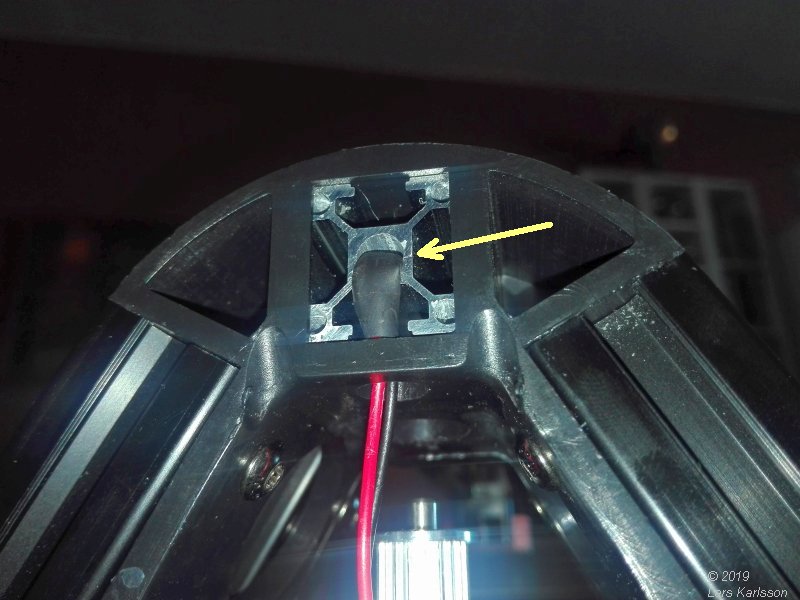

At the other end, the bottom I do the same.

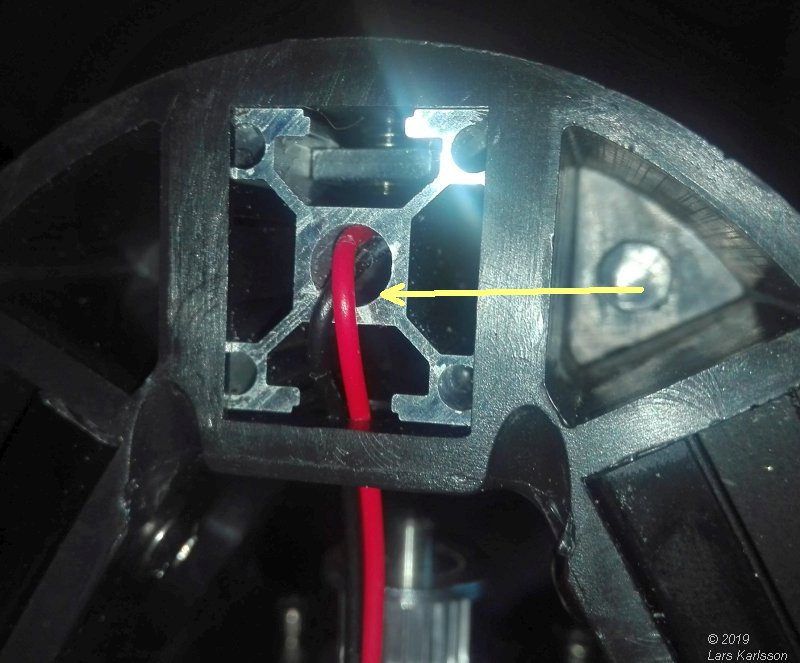

Very limited space, don't let the cables be twisted.

See how the cable go through the hole.

|