|

Advertisement / Annons: |

3D Printing:

|

Contents:

Note: |

2, Installing the pillars on the bottom frame:Mounting the pillars on the bottom frame:

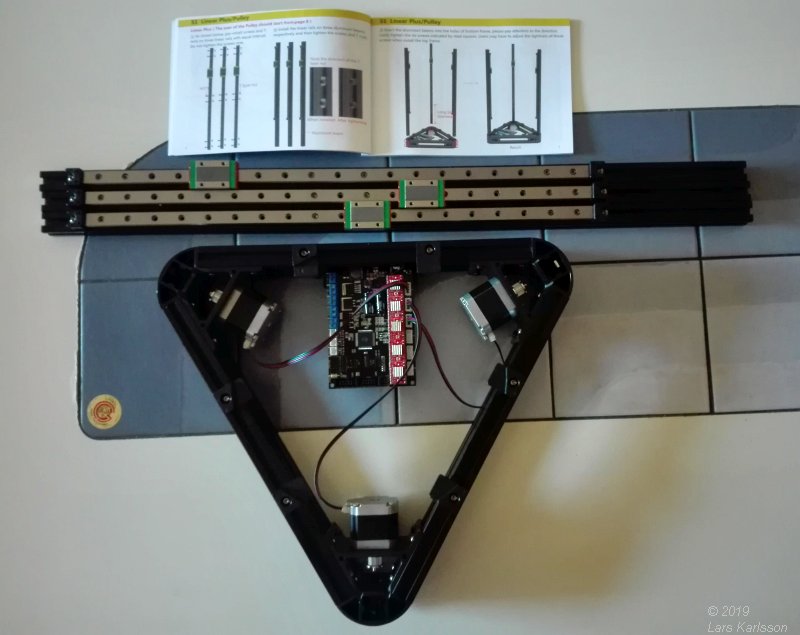

Next step is to mount the pillars with its slider on the bottom frame. The stepper motors and electronics are already pre installed in the bottom frame.

The easiest way I found to do this was to lay down the chassis on the table.

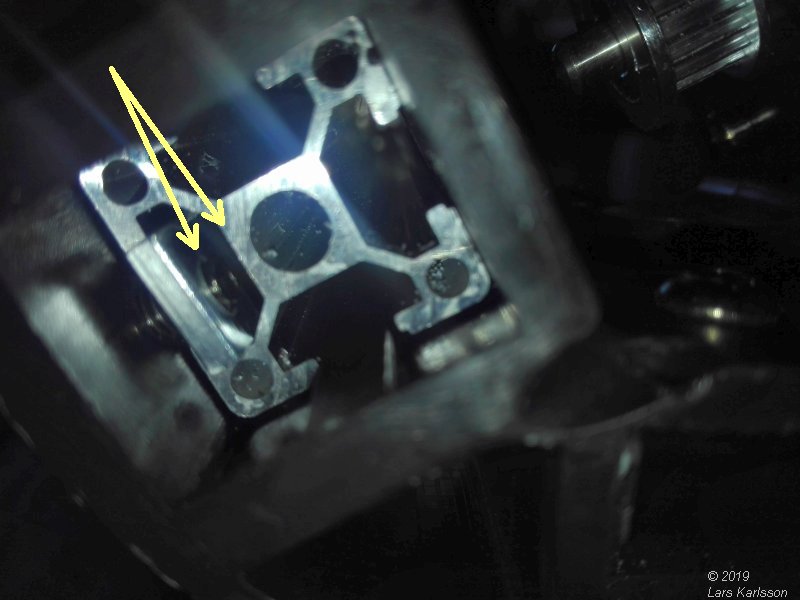

Slide in the pillar carefully in the frame. There are two nuts that must fit into place. The nuts are not square, they are rectangular and must be placed in correct direction, see the left arrow.

Push the beam all the way to the stop at bottom, it's plastic, do not use too much force.

Tighten the screws, now I got a problem. It was not possible to tight it hard enough. The screws was too long and hit the beam inside.

Check the screws, 10 mm long, they should have been about 2 mm shorter.

I didn't have any shorter screws at home but I had washers. Did a check and they was enough thick to fit. I placed the washers outside the frame against the screws' hat.

All three pillars are now mounted to the bottom frame, not any big problem.

|

|