|

Advertisement / Annons: |

My astronomy project:

|

Contents:

Related projects:

Note: |

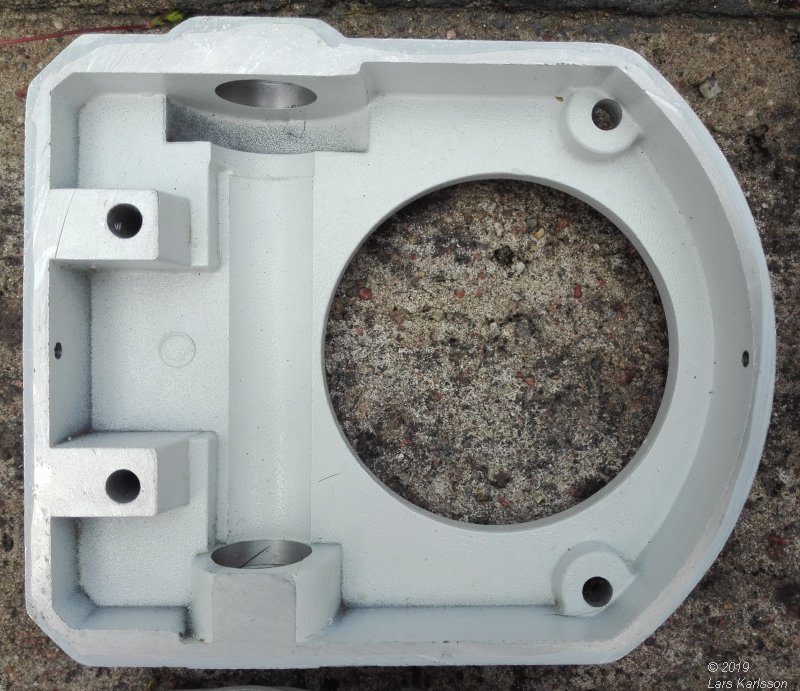

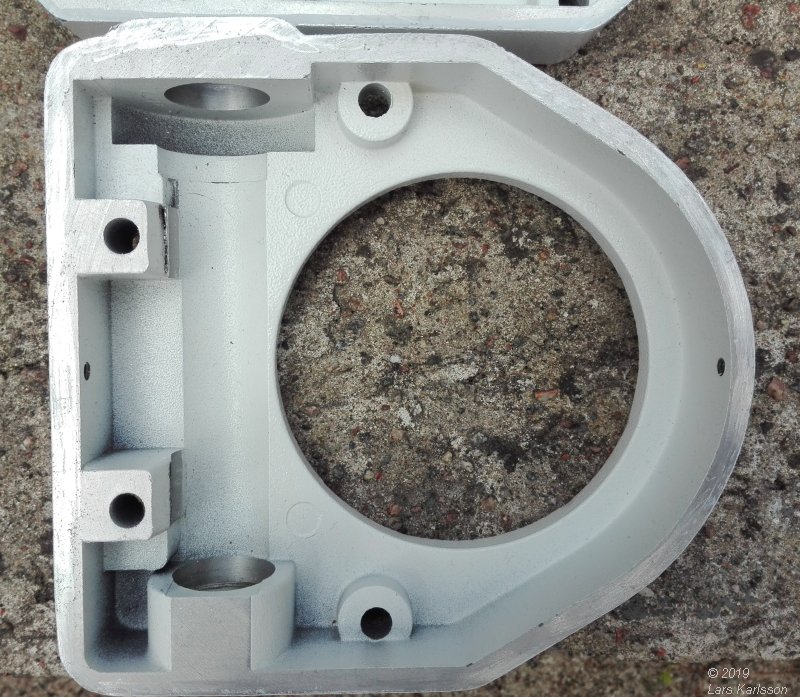

5, Lids to worm gears adjusted:The surfaces of the lids that cover the worm gear are used to have some paint on the surfaces. Something I want to remove. Worm drive's lid overview:

These lids slide along the chassis for DEC shaft and RA shaft, its purpose is to adjust the play in the worm gear. Common to find a lot of paint on the surfaces which is vise to remove. I plan to scrape off the paint with a knife and then file the surface flat. Note that the lids are of different sizes, RA on top. My toolbox. Worm gear lids:

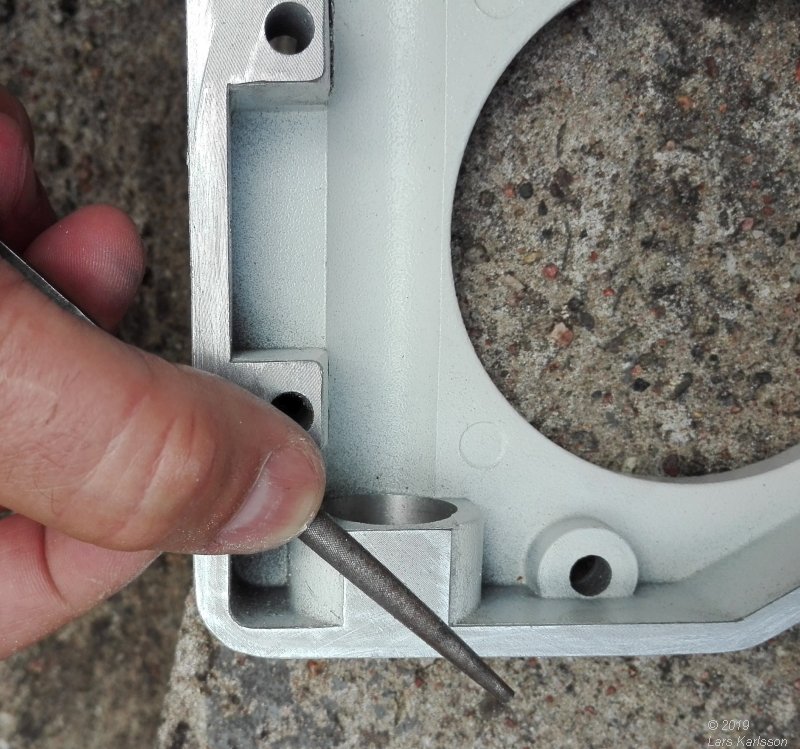

Here you can see the paint that I shall remove from the surface of the edge.

Scrape gently with the knife to only remove the paint, not scratch the metal.

A lot easier to do then I thought, look good to me.

The surface has some pits and hills, with a file I file the surface until it's flat. Hold the file parallel to the surface! You can also try to have a flat surface against the lid and a fine grid wet sand paper.

Here I file the inner edge in 45 degrees to get rid of the hill on the edge.

The same to the outer edge, from the beginning you can feel with the fingers that the surface is not perfect flat.. DEC chassis surface:

At this surface it's much more paint, and it's a roller bearing holder that protrude above the surface which make it more difficult. |

Starting to scrape off the paint on this surface too, that was not difficult either.

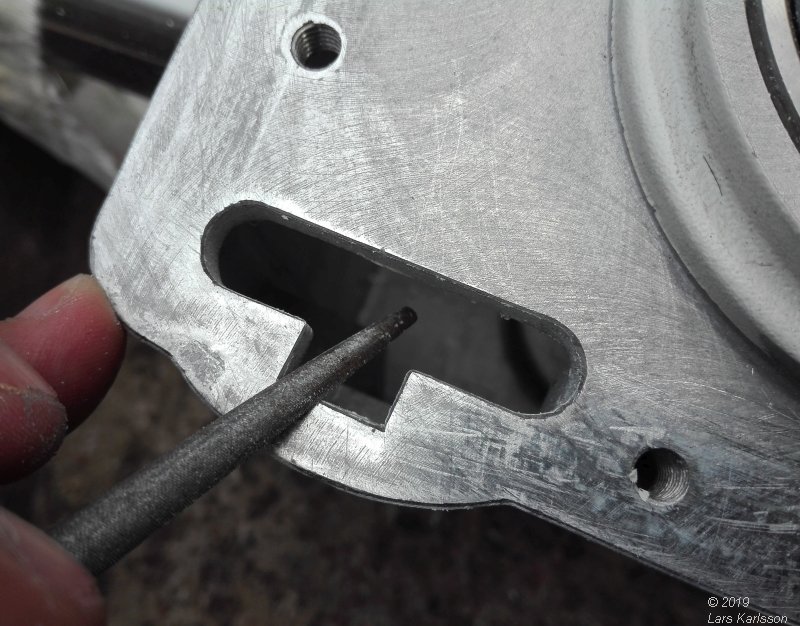

Run over the surface with the file. It looks like they milled the surface first and then drill the holes. The metal is a bit plastic and when they did the holes it made a crater rim around the hole. 60 teeth pulley:

Even around this surface I file the edges 45 degree.

This is the opening where the worm gear connect to the spur gear. I will have the timing belt through this hole. I file down all sharp edges, but later I'm sure that I have to open the hole wider to have enough space around the timing belt. RA chassis surface:

The last surface is the RA worm gear chassis surface. To my surprise this surface is not milled, very rough and lot of paint. If I had one big lathe I could have processed down the surface with it, but I do not have that equipment.

I check where it's most important to have a flat surface. I have protected the surface of the RA shaft.

Mark with a pencil the outer rim.

Start running over the surface with the file.

I don't file very deep, save the surface and maybe in future I can borrow the correct tools to get a better finish of the surface. Anyway it's much better now compare to how it was earlier.

|

|