|

Advertisement / Annons: |

My astronomy project:

|

Content:

Note: |

1: MechanicalI put my finest instrument, a TS130 910 mm f/7 APO refractor in the closet three years ago. An always problematic focuser get me to lost the interest. During these three years I have working with ideas how to build a better focuser. The main problem was the slip of the friction coupling, it couldn't handle heavy loads. During the years with help of a friend I have learn the basics in Linux and Arduino. Now I can build me my own DIY MyFocuserPro2 hardware driver and with new skills in the 3D-printing technology I can built the mechanical parts too. Now when I have a working focuser I will upgrade some small details on my TS130 and its peripherals. Problematic focuser. Dovetails:

The original dovetail, the black one, was too long, I couldn't move the dew cap all the way back. I have replaced it with a shorter dovetail, much better space around it now. Balance stop:

A small detail, the big washer makes a stop against the mount's head, the position when the DEC axis is in balance. Makes the setup time in the dark much faster. Motor focuser:

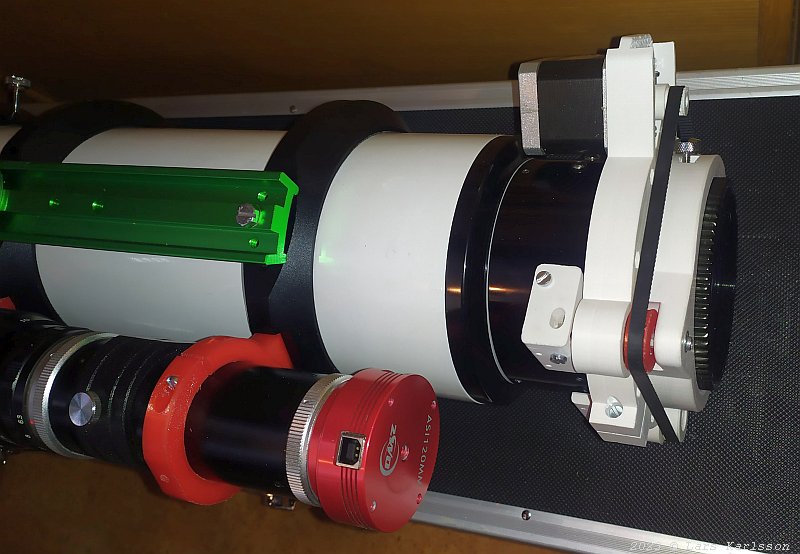

Later I will build an off-axis guider, but until then I use my guide telescope. It's an old telephoto lens, 400 mm f/6.3. I have 3D-printed new tube rings to it to get it closer to the main telescope. Makes it more compact and in better balance. The stepper motor is in the opposite direction to the guide telescope to get the system in balance, but need a bigger transport box to put the telescope in. Later with the off-axis guider it will not be a problem. To the right the motor focuser I designed and 3D-printed, it's a push pull design. You can read more about it here: Push pull focuser. Guide telescope:

I have to attach some antiglare tape on the dew cap now when the guide telescope sit so close to it. When focusing the guide telescope I have to open the front tube ring a bit, after focusing I clamp it and the focus will not move. Narrow space:

The clearance between the mount head and the guide telescope is only 2 mm. After tested it I found it to be enough. A handle on top of the telescope make the handling much easier, 185 mm center to center holes. It must be easily to remove to not make the transport box unnecessarily large. Made of aluminum or maybe 3D-printed plastic.

|

|