|

Advertisement / Annons: |

3D CAD:

|

Contents:

Note: |

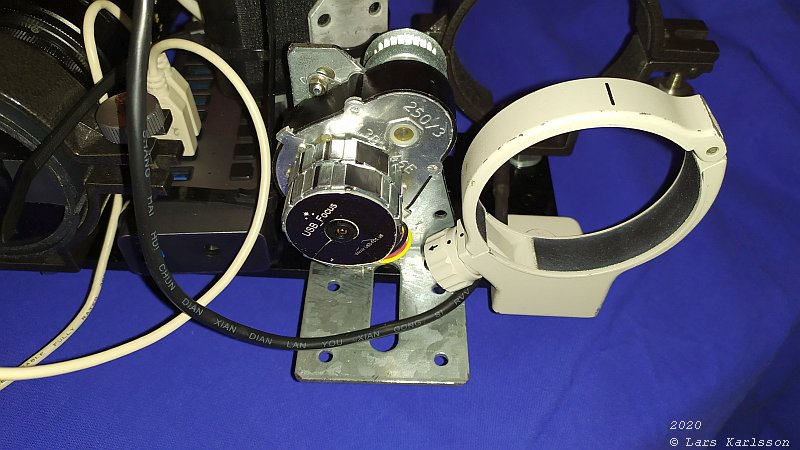

1, Calculating number of teeth:Introduction:Now when I got my 3D printer to work I have a lot of work to do. I have already printed a Star Adventurer adapter for the polar telescope finder. I have also a project with a Canon 300 mm lens, I need to focus it by remote and then I need some 3D printed parts. The stepper motor bracket CAD to the focuser is already started. The project on this page is about the pulleys I need 3D printed for the Canon 300 mm lens project. The Canon 300 mm L lens I plan to use already has a built in focus motor. But not so easy to take control over it, have a friend who is looking at it and how to do it. It will take some time and I have to start with an external focuser, I have the USB-focus middle model focuser that I can use to this project. Earlier I used it to my big APO TS130 refractor, but with all new items it got too heavy to that little focus motor. You can read about that focuser project here, TS130 focuser More information about USB-Focus:

Construction plan:How can I connect the stepper motor focuser to the camera lens ? I plan to use GT2 pulleys and a timing belt. GT2 is a common standard in the 3D printer world and there are a lot of parts to buy. The pitch (distance between the teeth) is 2 mm which give a high resolution.

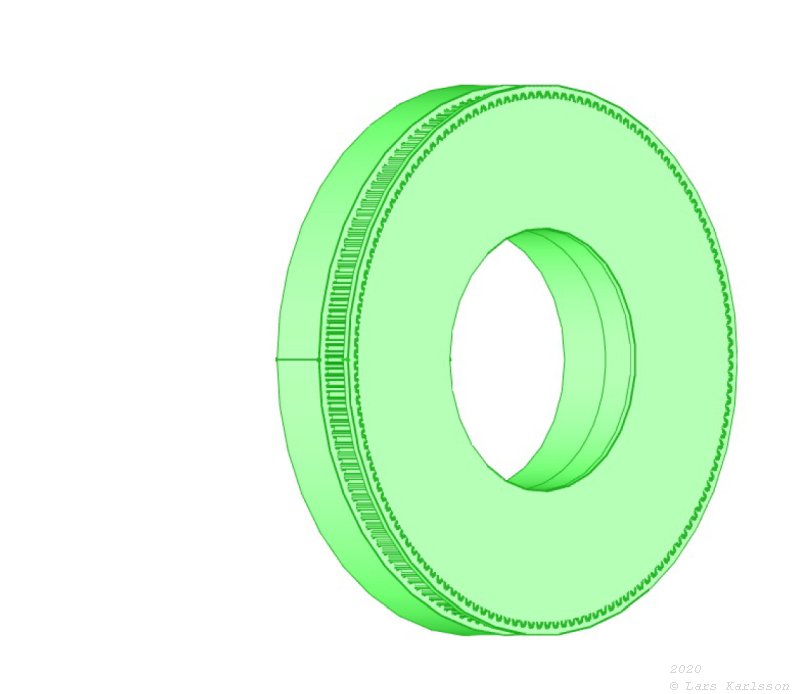

I use FreeCAD when making 3D drawings and have already test draw a big GT2 pulley in it. Very practical, I use a macro that I have downloaded and installed in FreeCAD. You only give some parameters and then it construct a pulley from it by automatic.

Update:

GT2 macro download:

Calculation of GT2 pulleys:

I must know something about the focuser to know how big the pulleys should be. I know from my earlier project that the USB-focus motor rotate just over 8 revolution in half step mode and 16 revolutions in full step mode from start to stop. Only the half step mode is interesting, it give the best torque. When focus the Canon 300 mm L lens I have to turn the barrel about 120 degrees. The barrel diameter is 74 mm. At the USB-Focus homepage can also be read that it does 8000 steps on the outgoing shaft of the gear box. 65536 / 8000 = 8.19 revolutions, that's what I get in half step mode. The other lens that I maybe will use is the Pentax 645 300 mm medium format lens, it's a manual lens and the barrel rotates about 240 degree from one end to the other end of focus. The barrel diameter is 80.5 mm. The driver of USB-focus is a 16-bit, that give the range of 65536 steps. What gear ratio do I need to use the stepper motor range most effective ? The scale must be so the focus barrel rotate a bit more then the focus range, in the focuser you set a limit for max move.

Update: Canon 300 mm L lens: Ratio: 8 / (120/360) = 24:1. The maximum diameter for the Canon lens is about 115 mm with standard Canon lens holder, it gives about 180 teeth. The small pulley has to have something like 8 teeth, it's impossible, maybe 12 teeth. It will not use the full range, only use about half of it, 32000 steps but still it will work I think. With optimal gear ratio 180 / 8 = 22.5 (this will be a very bad pulley with only 8 teeth) Angle resolution: 360 * 8 * (7/180) / 65536 * 60 * 60 = 7.0" (arc seconds) or With optimal gear ratio 180 / 16 = 11.25 (16 teeth or more is what is recommended in a pulley system) Angle resolution: 360 * 8 * (16/180) / 65536 * 60 * 60 = 14.1" (arc seconds) One step of the focus motor will rotate the focus barrel 14 arc seconds. Don't forget that the Canon lens had only 120 degree angle from one end to the other end of focus, it only use half of the steps (32250) with a 16 teeth pulley. Pentax 645 300 mm ED lens: Ratio: 8 / (240/360) = 12:1. The maximum diameter for the Pentax lens is more free to use, but take the same 180 teeth pulley. The small pulley has to have something like 15 teeth. It must have some extra rotation so 16 teeth will be good. Angle resolution: 360 * 8 / (16/180) / 65536 * 60 * 60 = 14.1" (arc seconds) One step of the focus motor will rotate the barrel 16 arc seconds, it must be good enough. It will use the full range, 65500 half steps (the focus barrel rotate twice the angle). Because of this lens mechanical construction it's better suited, and even if it's a manual focus lens it have some extra room to focus beyond infinity. It will be very interesting to test this lens, a medium format lens it will have very low vignetting when used on a 35 mm camera. The question is, is it sharp enough ? The Pentax ED lenses are very sharp in the 1980s. I don't have to buy new pulleys, I 3D print them to almost no cost I can do some experimental test. I start with the small 12 as a test only and a 16 teeth pulley. |

|

|