|

Advertisement / Annons: |

3D CAD:

|

Contents:

Note: |

9, CAD of 174 save and prepare to print, part 4:This pulley have some overhang, that means that the printer can't print it without some support. I activated Support in Cura before I let it slice it. If I had planned the design better maybe I didn't need this support. This pulley is much bigger and contain a lot of plastic, I made it hollow with an inside structure to strength it. Save printing time, plastic and weight. Printing the big 174 teeth pulley:

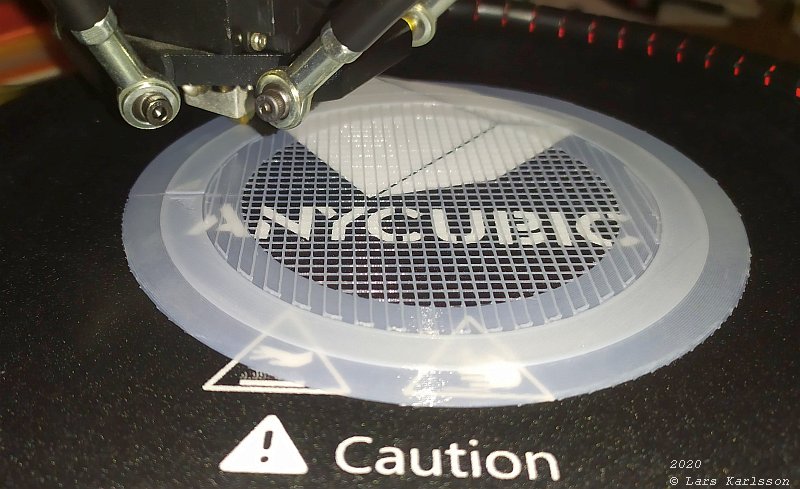

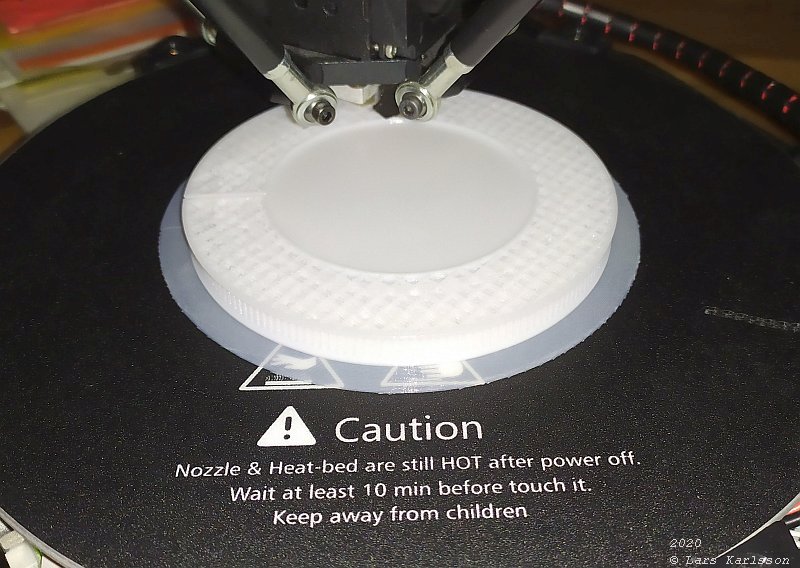

The raster in the center is the support that's building up to handle the overhang. The outer rim is only to hold the object more safe to the printer bed. It will a lot of after work to clean the pulley from all these support.

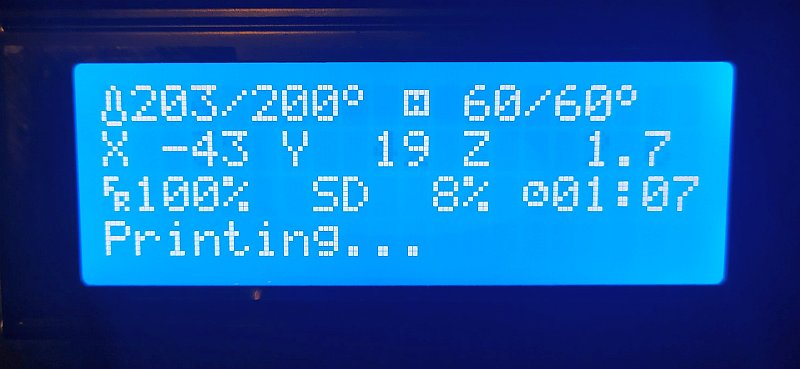

Oioio and oioio it sounds, long time waiting, almost a whole hour has passed and only 8 % completed. It's a long nervous wait, it's like a new baby is coming.

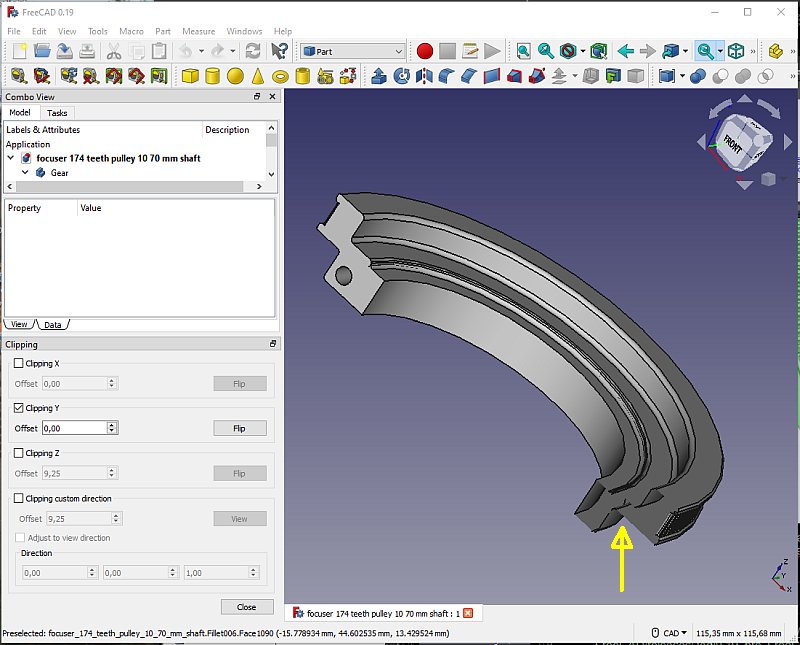

Meanwhile the 3D printer working I did some investigating about what I had designed. Is it too weak in some points ? I search internet for tools that I can cut through my design and see how it looks. There is the Clipping tool built into FreeCAD that I can use. At the arrow I was a bit suspicious about if it was too narrow and weak at that point. But it looks okay, enough with material.

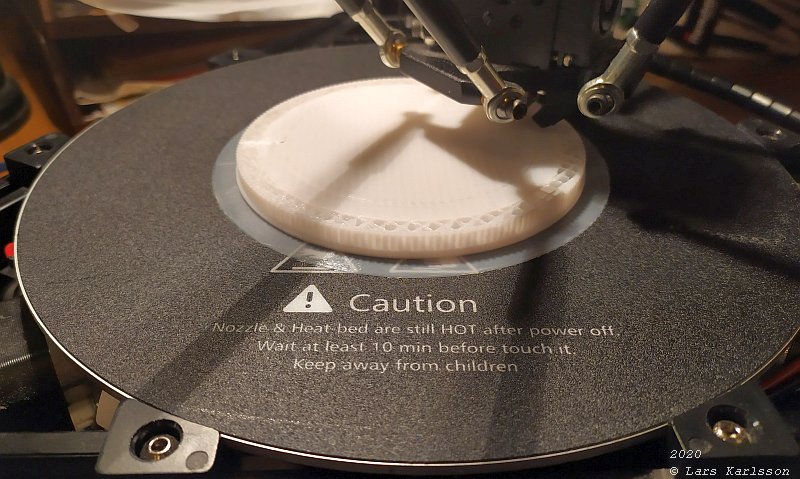

Take a nap and wake up for a check, 4 hours of printing.

It's now half way, all teeth almost finished. The support in center is huge.

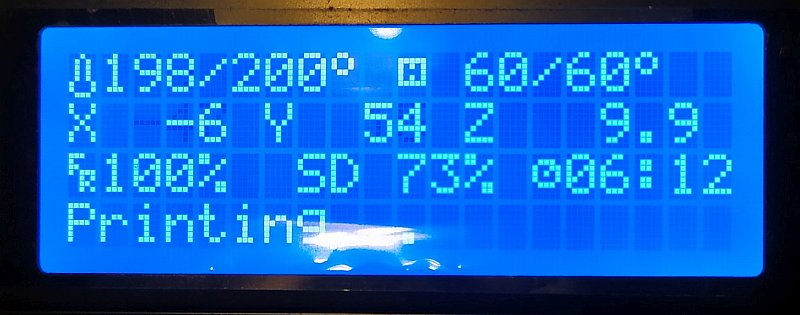

One more check, now 6 hours and 12 minutes, still printing.

Top layer is now printed, it will be the hub that lock to the lens barrel.

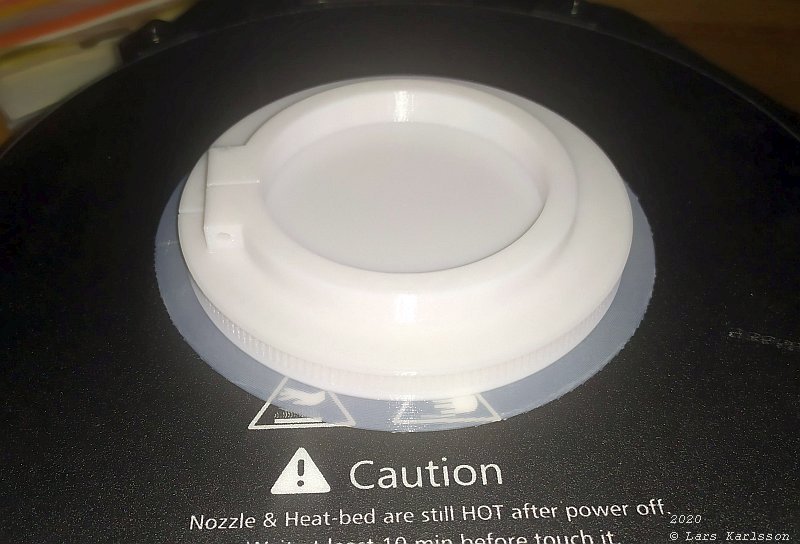

Early in the morning, it's finished ! 8 hours and 30 minutes. I think if I redesign it so it don't need support I can print it in 5 hours.

What a nice look ! |

|

|