|

Advertisement / Annons: |

3D CAD:

|

Contents:

Note: |

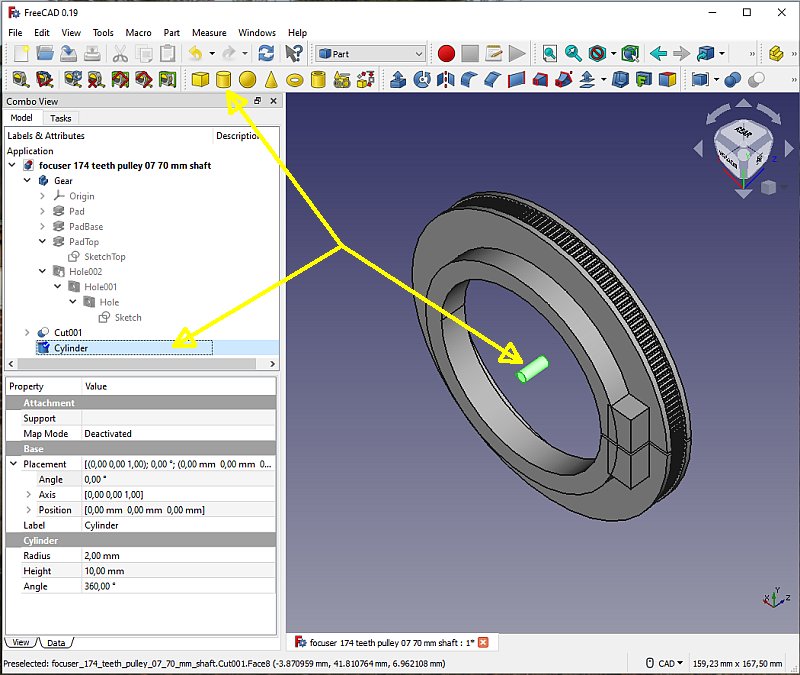

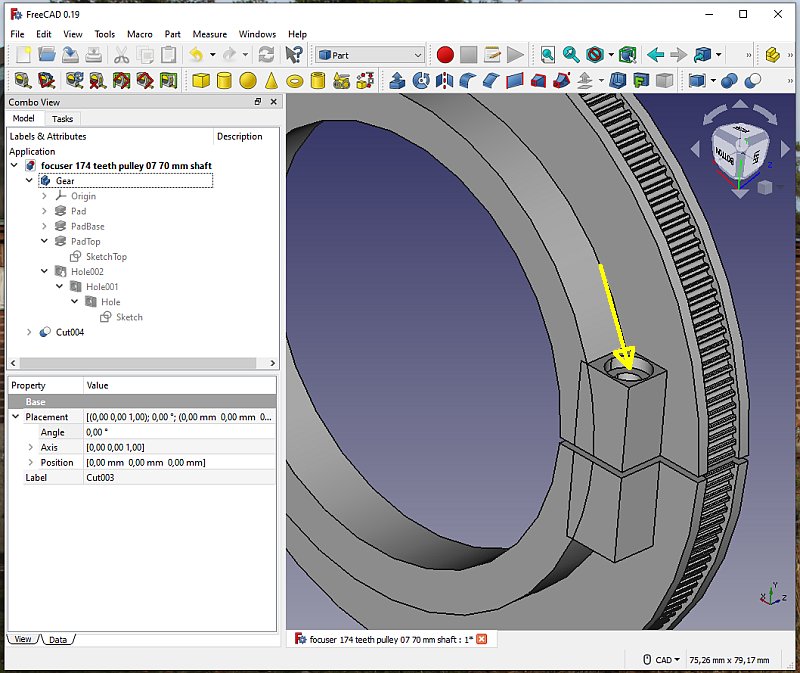

8, CAD of 174 teeth pulley, part 3:I had some problem to make holes in the locking mechanism. I solved it but maybe not in the smartest way. Make holes to the lock screw:

I have to use the subtraction method once again. Start with a cylinder. This will be the hole to the lock screw.

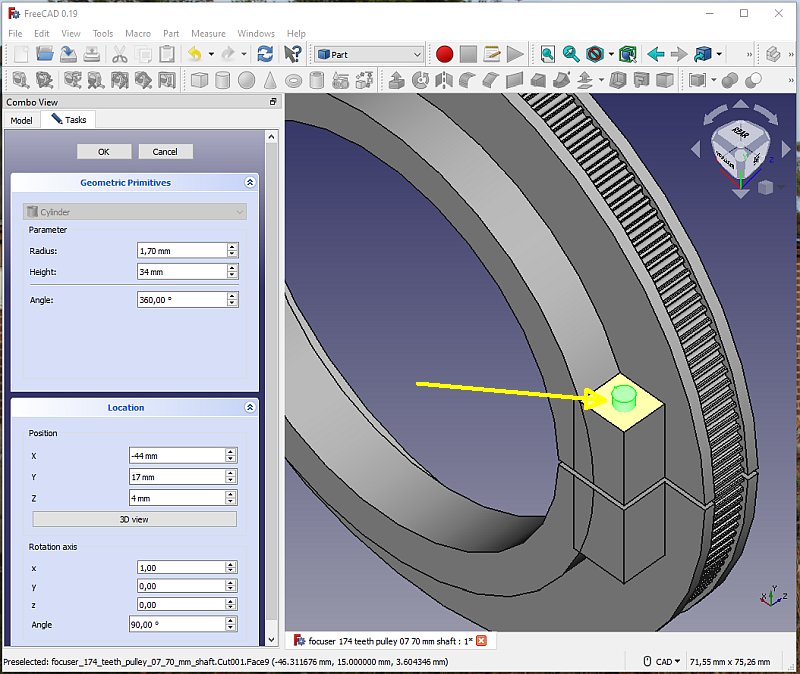

Adjust the size, it's a M4 screw, start with the diameter for the thread, 3.4 mm. Move it to center of the block that hold the lock mechanism.

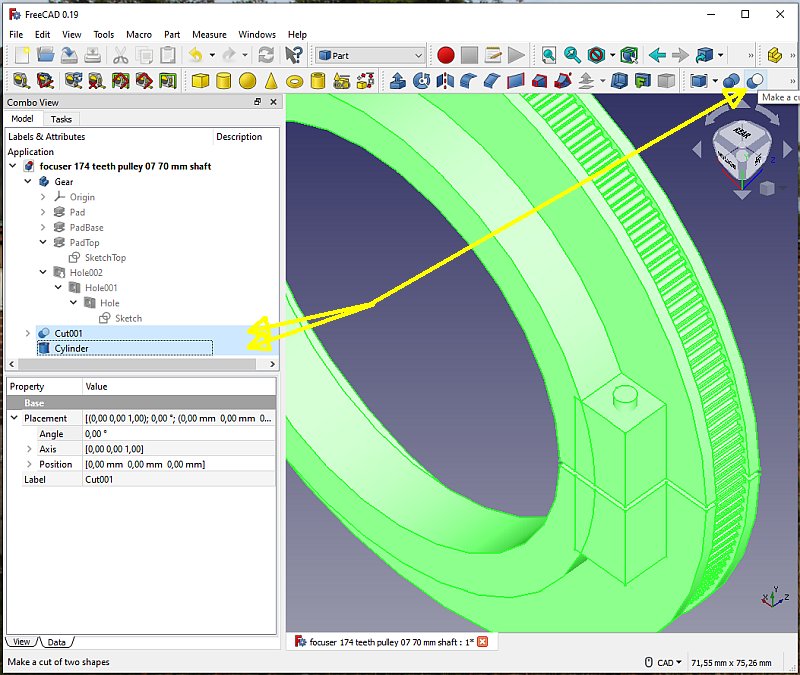

Subtract the cylinder. Making a new hole outside the earlier:

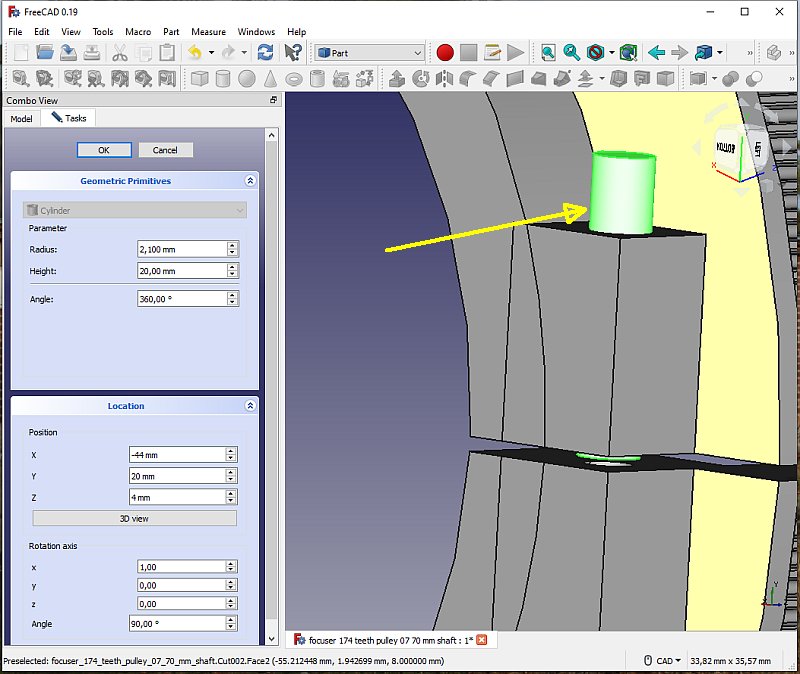

Make a new hole outside the earlier, this time it has a diameter of 4.2 mm, M4 screw. Only in the upper part.

Make a third hole outside the other. This upper hole will let the screw's head sunk in. It had would be nice even to let the nut be hidden like this but the tool didn't work on this surface. Trim the edges:

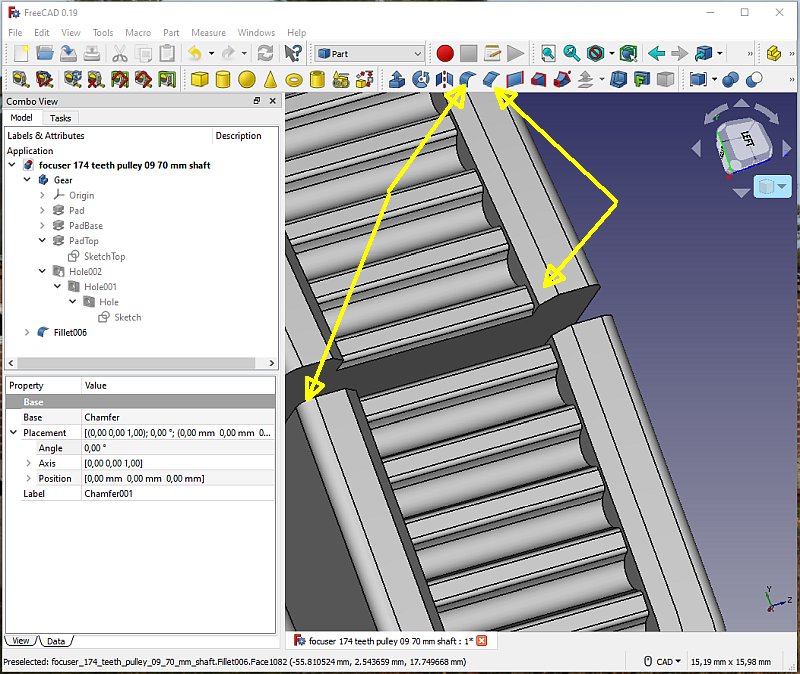

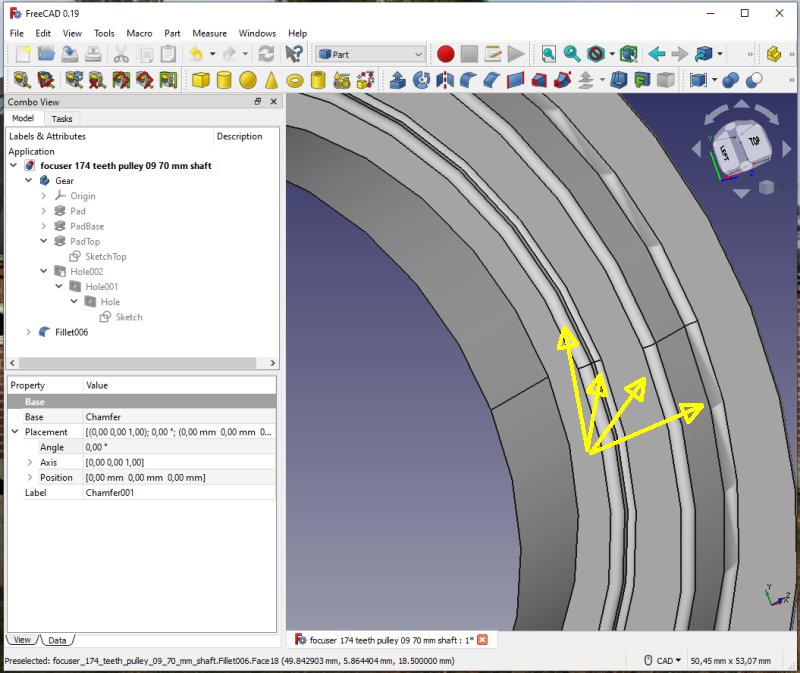

This is something I must implement on the small pulley also. Round of the edges and make an angle of the flange's side towards the belt. It will direct the belt towards the center of the pulley.

All edges on the front and backside are rounded, looks much more professional now and no sharp edges that cut your fingers. |

|

|