|

Advertisement / Annons: |

3D CAD:

|

Contents:

Note: |

17, CAD of 180 teeth pulley, part 3:Now it's time to print out the pulley. Very exciting if it will fit this time. 180 teeth pulley, Export it to Cura as a STL file:

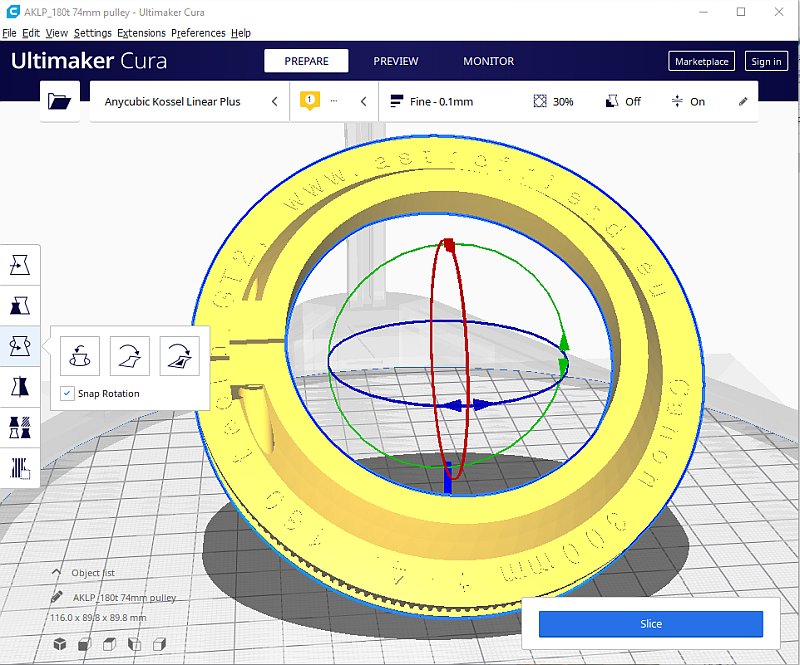

I Export the drawing as a STL file to Cura, the slicing software. Yes, it looks correct, if it looks okay in Cura it will normally be printed correct also. Testing the printed pulley on the lens:

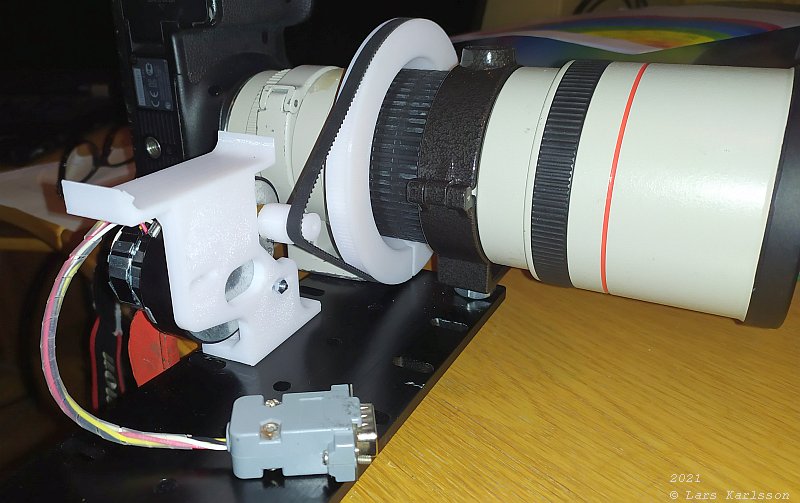

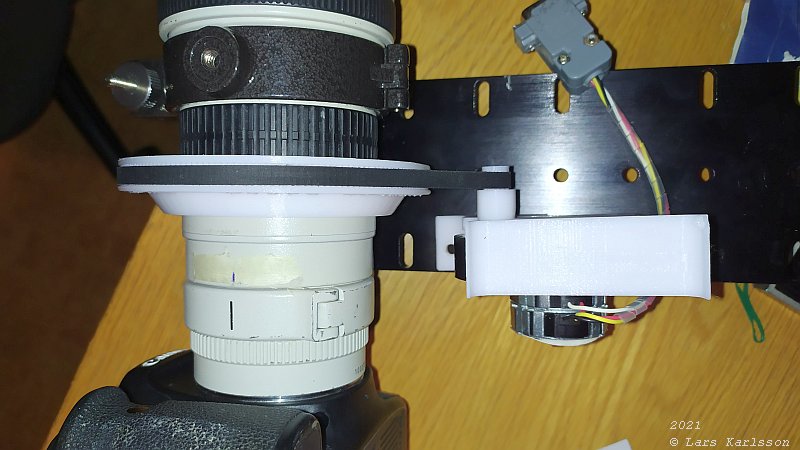

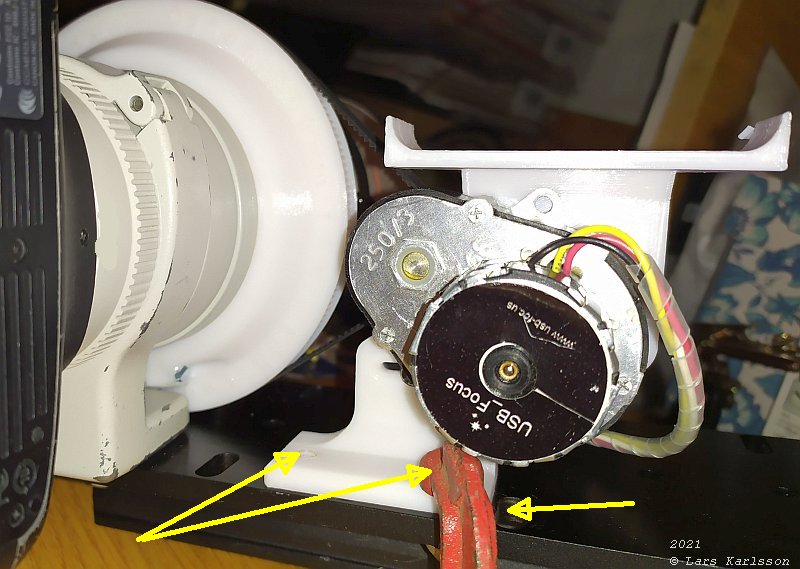

There where no problem this time with the 3D printing. It fit the lens barrel and the timing belt wraps round perfect to the teeth of the pulley. It's a GT2 pitch 2 mm and 400 mm long timing belt I use.

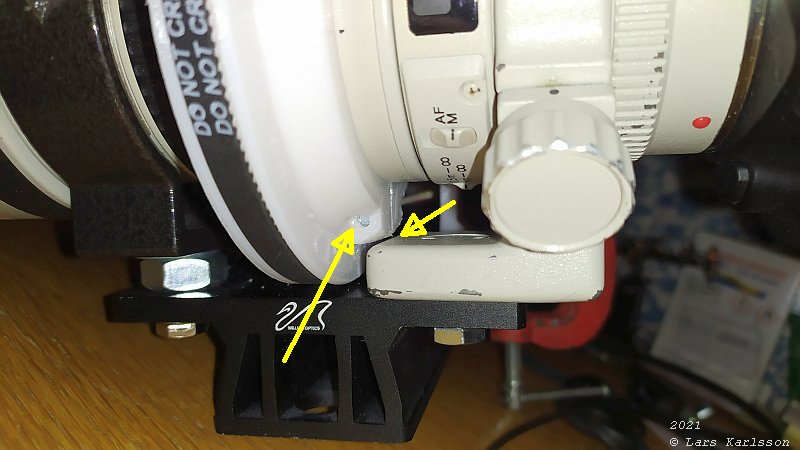

As a bonus I got the pulley to turn all they way around without hitting the lens holder. It's not necessary but it's safer to have it like this. I had to nail down the corner that protrude, I will update the drawing later. The control buttons are hard to reach with the camera in this position, but no need to use them. If there is space enough I will place a pocket here instead of the threads, with this new slimmed pulley it wasn't so easy to thread the hole.

I must print out a new 16 teeth pulley before I can proceed with the new version of the motor bracket.

Later when the new 16 teeth pulley is installed I can measure where I shall have the mounting holes to get the correct tension of the timing belt.

It was a lot of work to understand this text tool, but very handy, if I 3D print a lot of this pulleys for different lens' it's now easy to know which is which.

To do list of the 180 teeth pulley: |

|

|