|

Advertisement / Annons: |

Project:

|

Contents:

Note: |

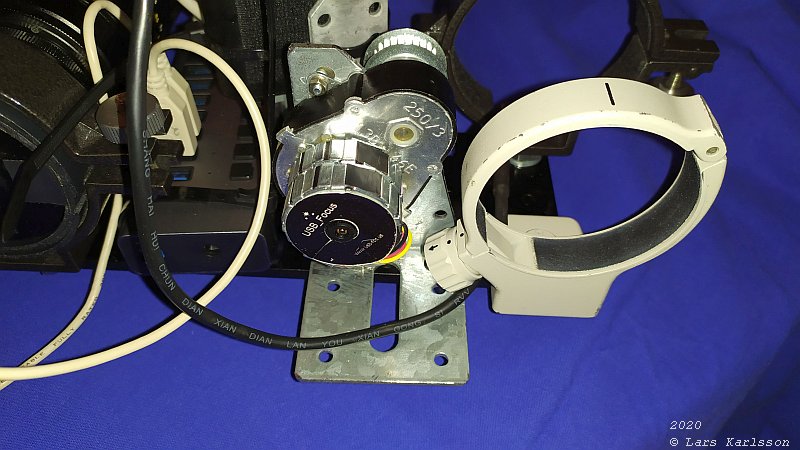

4: Mounting bracket for motor focuserEven if the Canon lens already has a built in motor focuser I want to install my external USB-focus, because I maybe change the lens to one without built in motor focuser later. Mounting bracket:

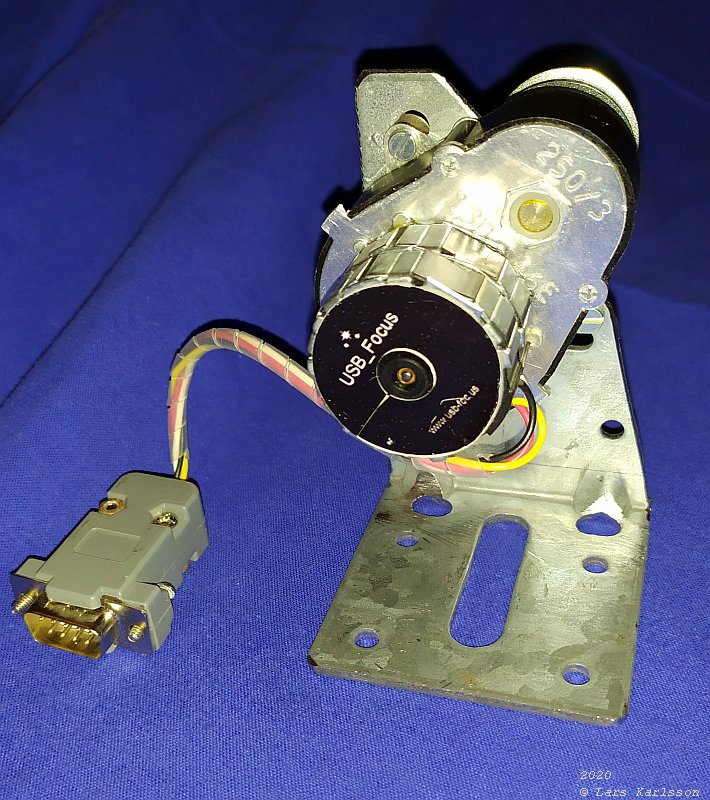

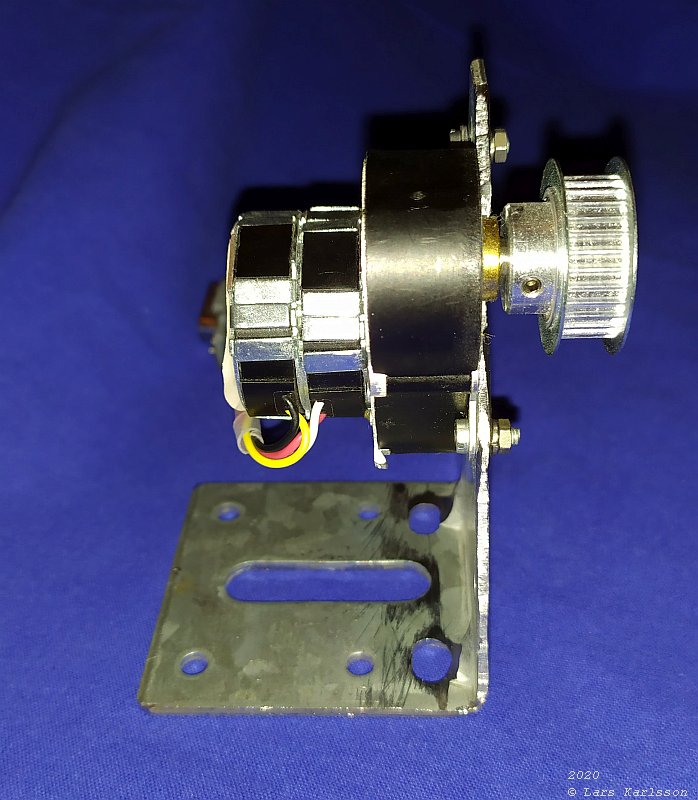

An ordinary mounting bracket is used to hold the stepper motor of the focuser. Drilled some new holes and cut parts of it. In the future, I will 3D-print all such mounting brackets. Then I will be able to make much more special design of them and I can have them online for download to you who find it useful.

The stepper motor installed on the bracket.

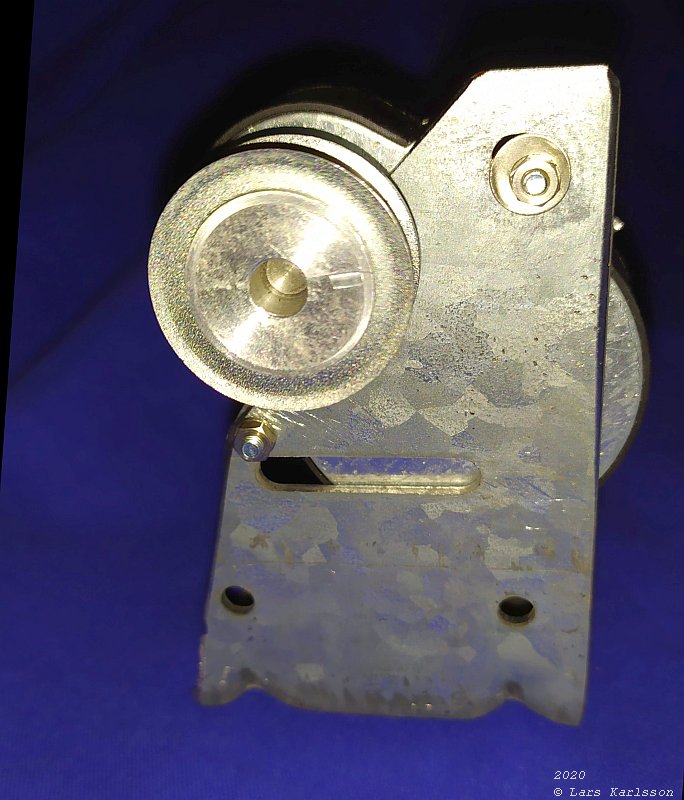

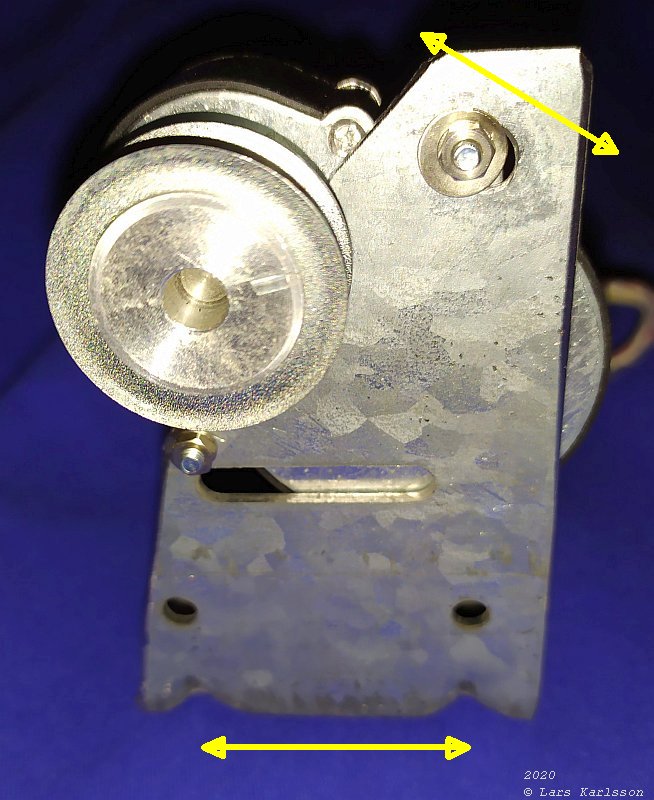

With the screw in the upper hole I can adjust the position of the motor.

Now it's in its most right position.

And now it's in its most left position. The axis of the motor moves about 4 mm between the stops. I can also slide the hole bracket along the Vixen tale, 10 mm. See this as a model I need before I start 3D CAD it for 3D printing, you can follow the progress here: 3D printing a bracket. Overview USB cables:

I had to rearrange all the parts on the Vixen dovetail to have a better fit. But it's very limited space around the motor focuser. I also moved the USB Hub from the lower side of the Vixen dovetail to upper side.

EQ Direct adapter for the EQ6 mount and the QHY5 guide camera in its holder.

Later I can cut the bracket's lower part that stick out. It make it easier to reach the release knob of the lens holder. |

All cables to the USB Hub are now short 25 cm cables. Extra camera holder:

Most right is the extra holder for my friends cameras.

The two blue buttons in middle are the manual focus in and out. Later when I found a tube holder of correct size I shall install it at the front of guide lens. At left the temperature probe.

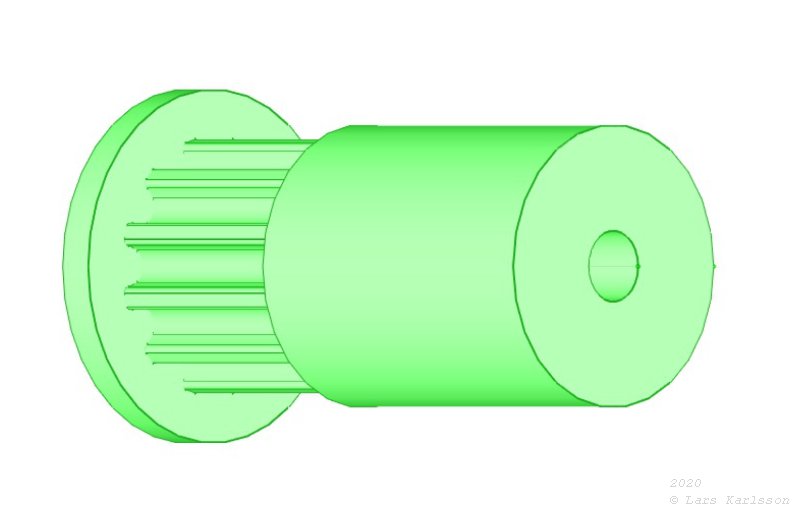

With the 300 mm lens installed which is not so easy because of the limited space. The timing belt, the plan is to have a free rolling pulley to the right that stretch the belt and set a symmetric force on the lens. CAD Pulleys:I'm in the learning process to use FreeCAD, when I can create my own drawings I can 3D-print all holders or what I have need of. Just now I'm practicing to print GT2 Pulleys.

My first pulley. It's a GT2 pulley with 12 teeth. I need a 6 mm bore hole in it. Too large to have it where the teeth is, I added some extra length to the right to have it to work. You can follow my path to a 3D printed pulley here.

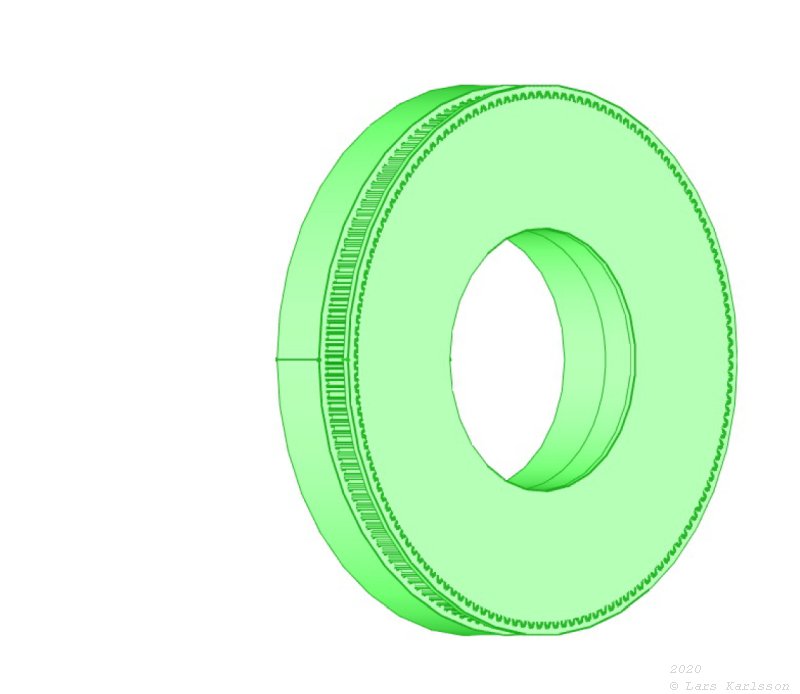

This is the other pulley. It will squeeze around the lens' focus barrel. It has 144 teeth and a diameter of 95 mm. It's in early stage, the center bore will be much bigger, 74 mm. Focuser:

The black cable in middle is the temperature prob. The motor focuser automatic adjust focus when the temperature changes.

The dew heaters are not installed yet. The new ones I have ordered are much smaller and does only cover the critical area, just behind the front lens. I can then lower the power to it, from 2 Watt to 0.5 Watt.

Still some free ports left.

|

|