|

Advertisement / Annons: |

Chrysler Crossfire

|

|

4, The last design:

What I thought will happen, the hook will snap off. If I 3D-print with another filament I can get it stronger, but even better is to alter the design.

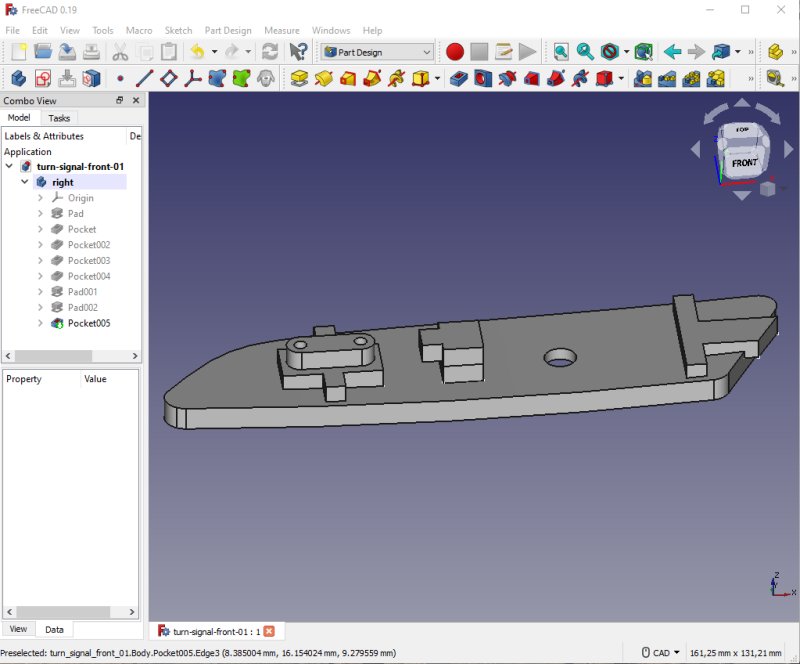

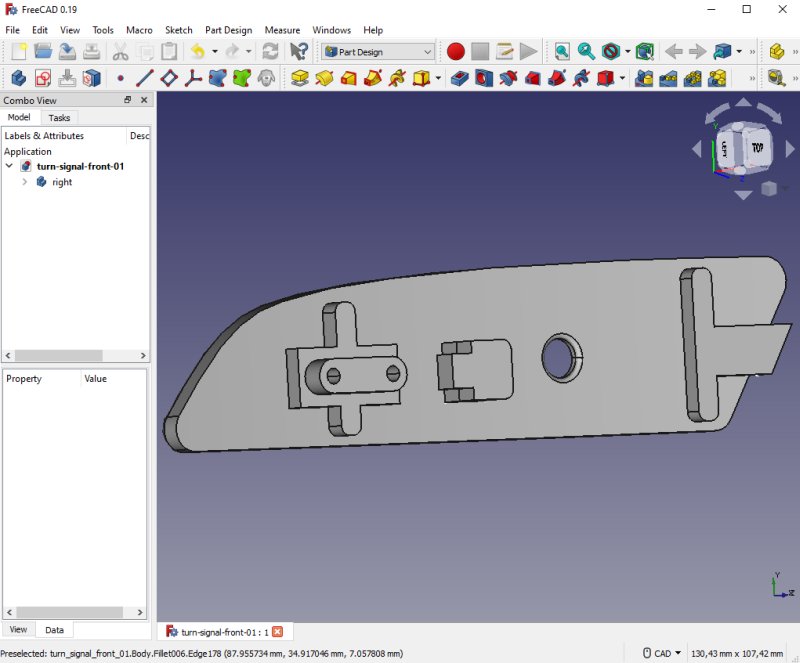

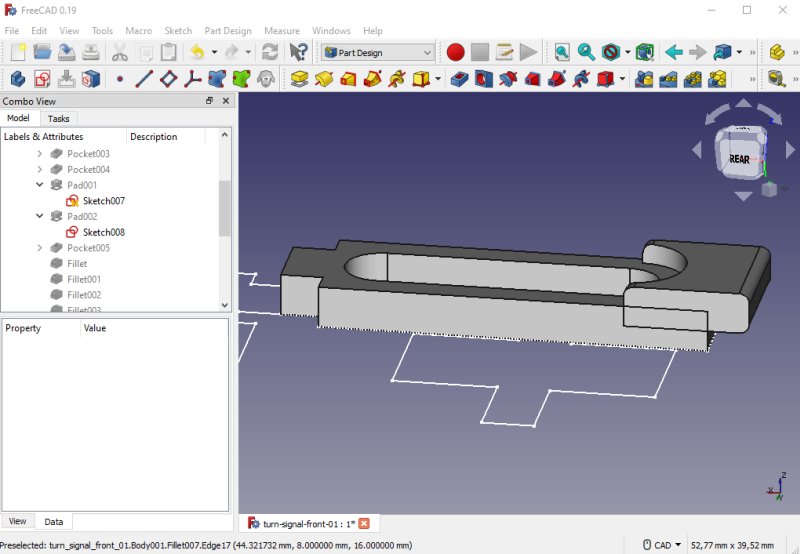

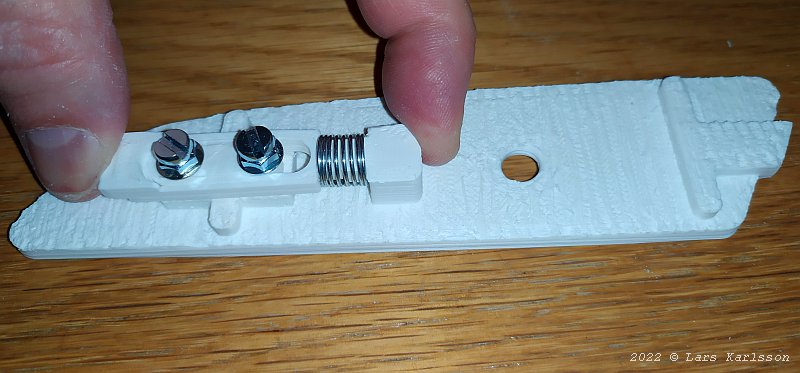

This is the new design, the hook is replaced with a sliding lock. The sliding lock will be hold in place by two M4 screws with a big washer. A spring of steel will act on the lock slider and push it in correct position. That part will be designed later. This is thought to be the last prototype.

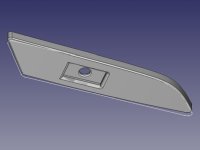

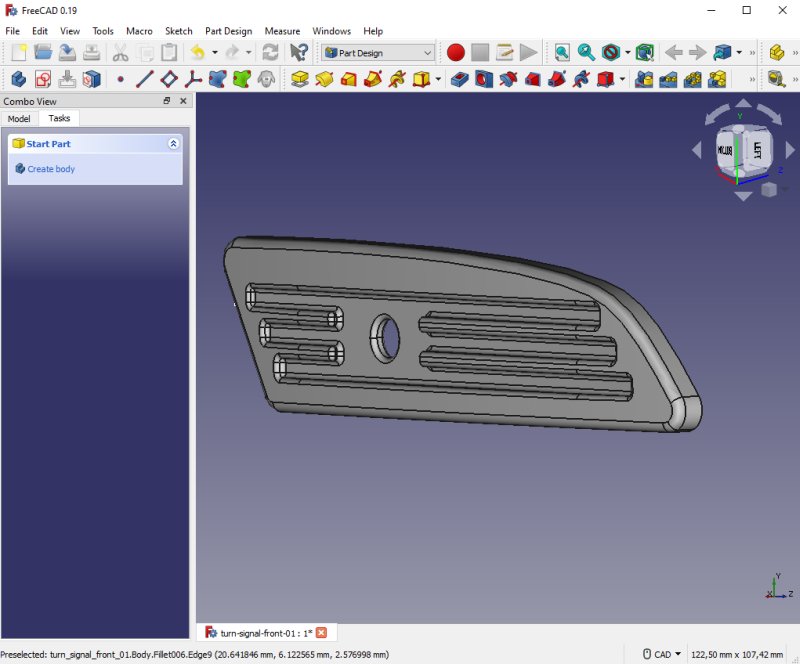

On the front there are no changes to the design more than that I added one more rounded edge.

Even on the backside there are some places with rounded edges.

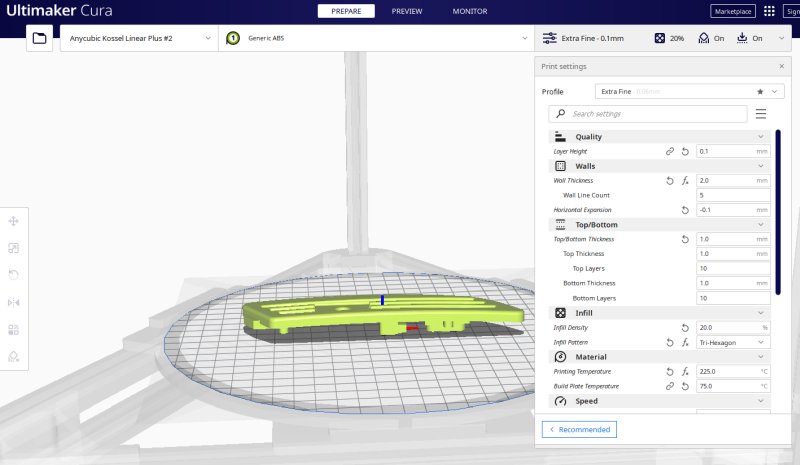

Now when the prototype prints are over I tweak the parameters to give better quality. To get a smother surface I print it with the front upwards, I set this in the slicer program Ultimaker Cura. I also set the profile to extra fine, 0.06 mm. 3D-print with support and a brim. With all these settings the printing time will be more than 6 hours.

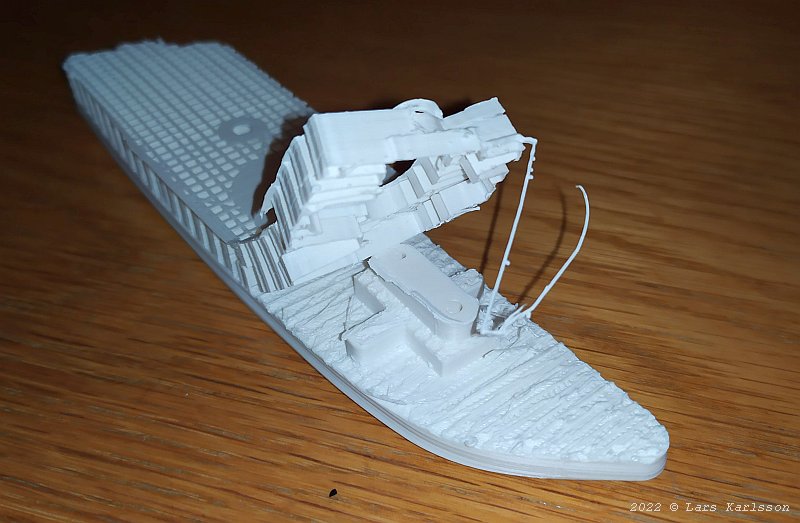

Carefully take away the support. Lock mechanism:

This is the fist outcast for a lock mechanism.

A quick 3D-print, just 17 minutes.

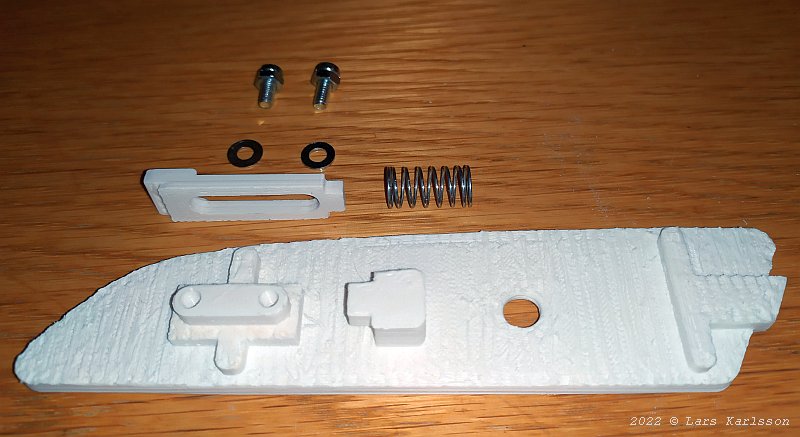

To mount this lock mechanism on the adapter a steel spring is needed and two M4 screws with washers.

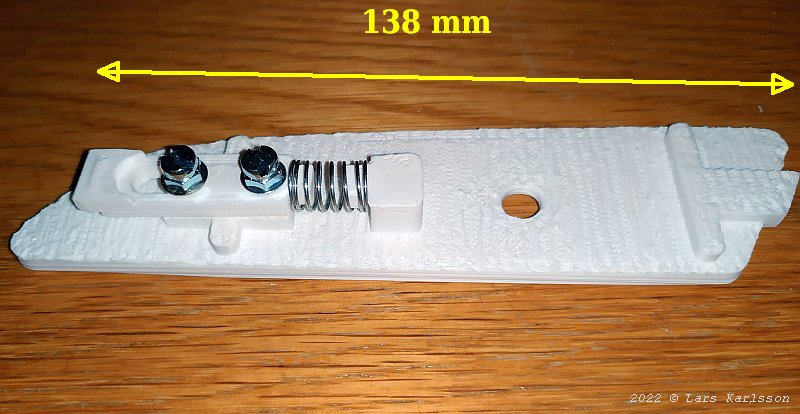

In outward position the length is 138 mm, the fenders rectangular hole will stop it at 134 mm.

Fully pressed in the length is 131 mm, that is needed to get it in the rectangular hole in the fender. This construction went much better than the original 3D-plastic leaf spring. I have put the 3D STL file for download here if you want to test it: CAD Chrysler Crossfire turn signal adapter .

|

|