|

Advertisement / Annons: |

Chrysler Crossfire

|

|

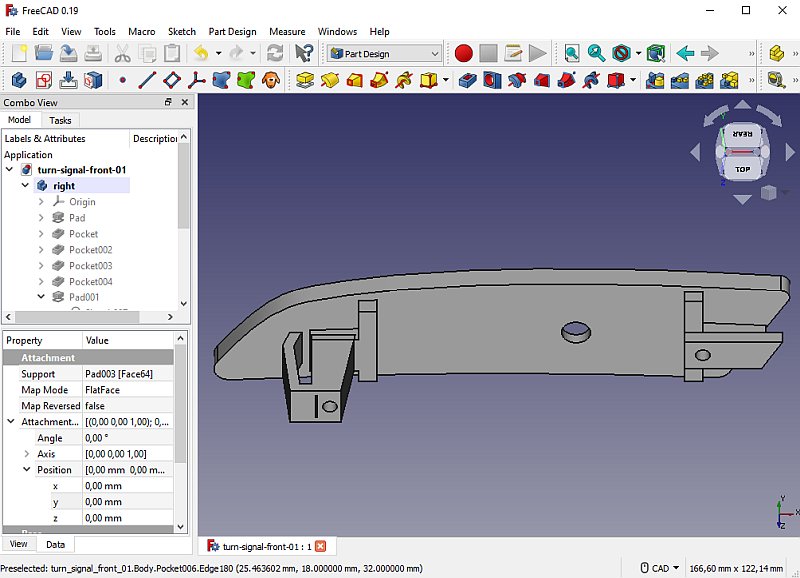

3, Lock mechanism and guiders:

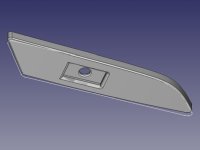

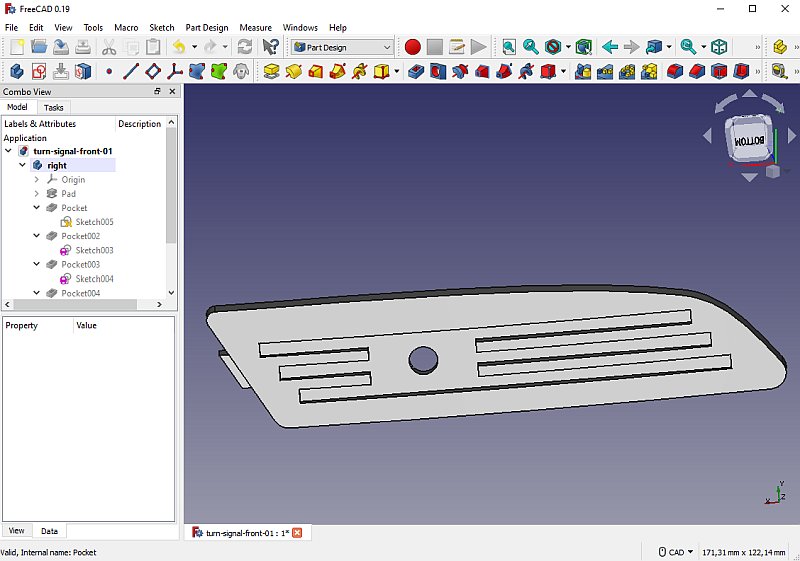

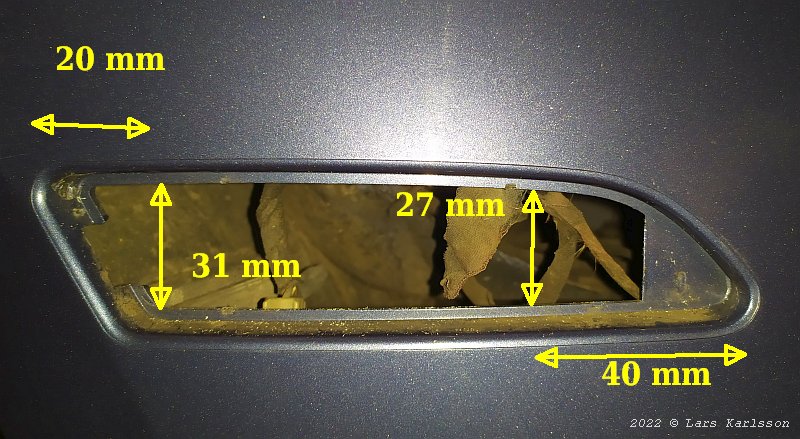

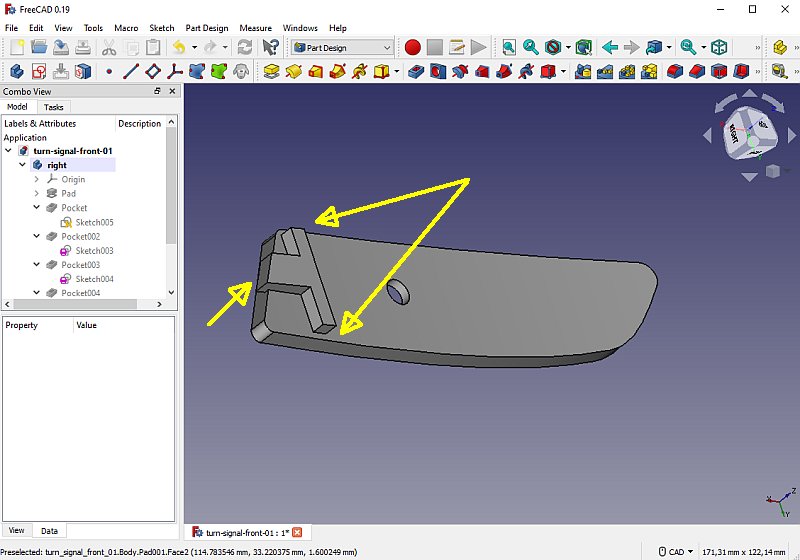

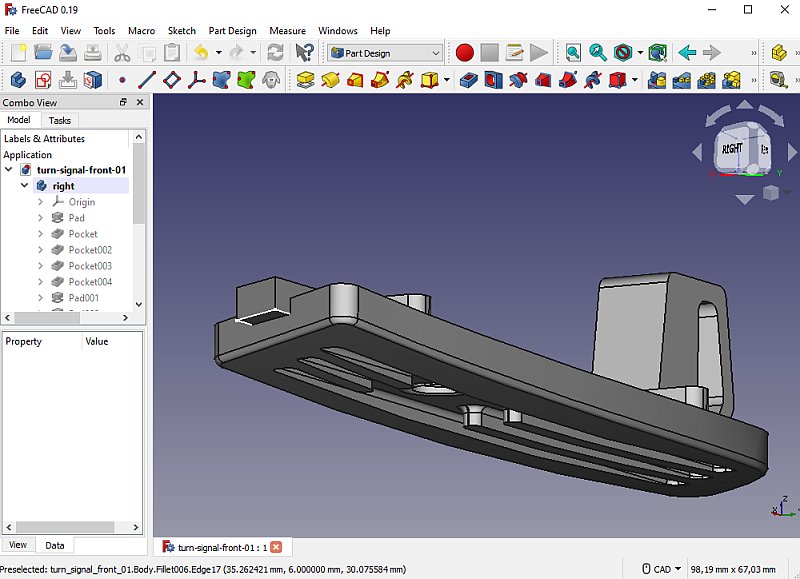

I have now fine adjusted the shape and size of to fit better to the fender. At the same time I gave it a more Crossfire look. I'm not an artist but to me it looks much better. It will have rounded edges later.

This is a sketch where I have to place the tabs, the once that center the adapter in the hole.

On the backside I have started to add the devices that hold it in place. To the left is the lock tab, it goes in on the backside of the fender. It will be adjusted for the thickness of the fender later. The two others to the right is the tabs that guide the adapter to sit in center in the hole in the fender.

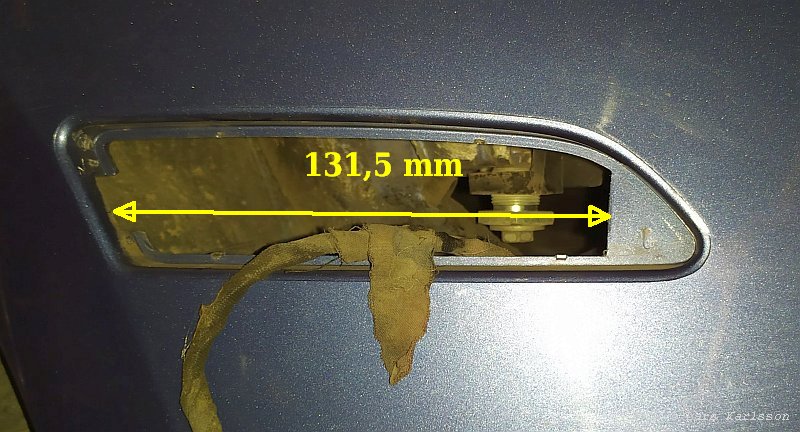

I must also know the distance between the end stops. The thickness of the plastic fender is about 3.5 mm.

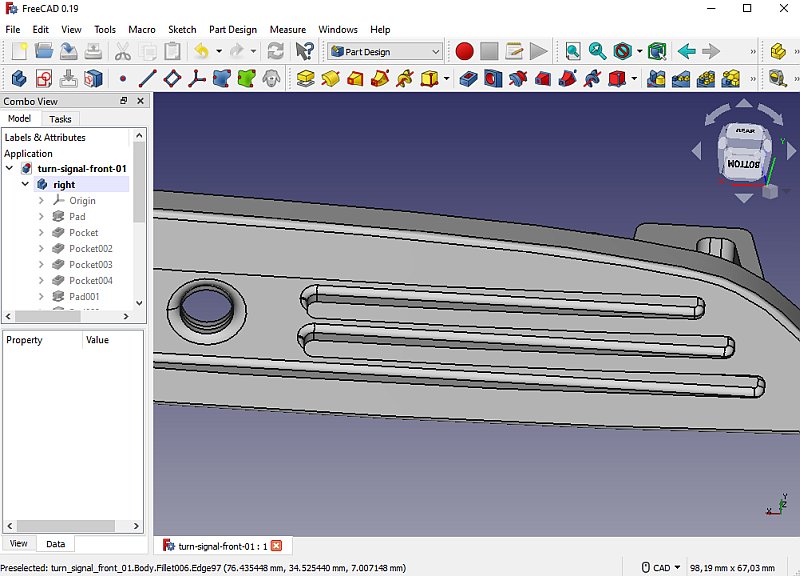

Many hours later, now it looks as the original clamps and brackets. If the 3D-printed leaf spring fail I have made a pocket for a steel leaf spring. There is also an alternative hole that can be drilled for M5 screw.

Some details before printing.

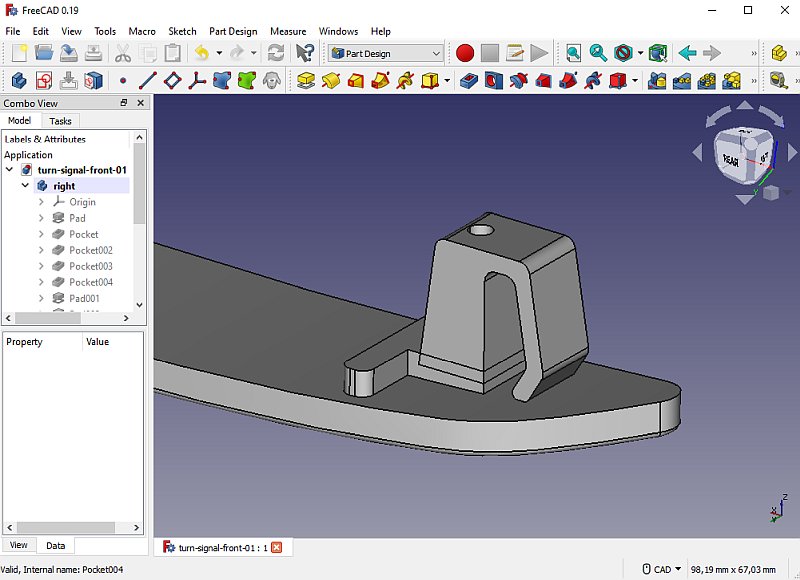

Front lock with 3D-printed leaf spring. I had to omit the slit for the steel leaf spring, it had weakened the construction too much.

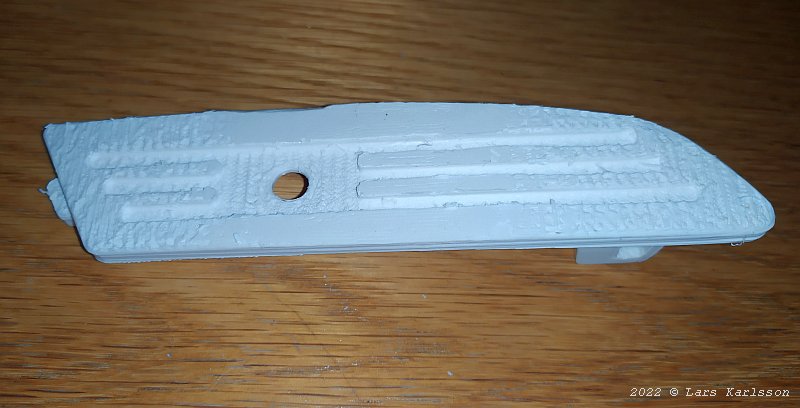

Back lock tab. Now I'm close to be finished. This time I print with 0.1 mm resolution, twice compare to earlier. But also take much longer time, 4 hours.

I had this side downwards when I want to 3D-print faster that's why the surface is so coarse.

The hook to the right is very fragile, must find another design.

It fits now but it must be 2 mm shorter, that was what I extended it earlier. It need some room when move it forward to take it away. The upper left corner need a bigger diameter.

|

|