|

Advertisement / Annons: |

My astronomy project:

|

Content:

Note: |

4: GearsThe filter gear has to connect to the stepper motor shaft in someway. Belt drive or gears ? I felt that a gear construction is the most easy way to solve it. Gears:

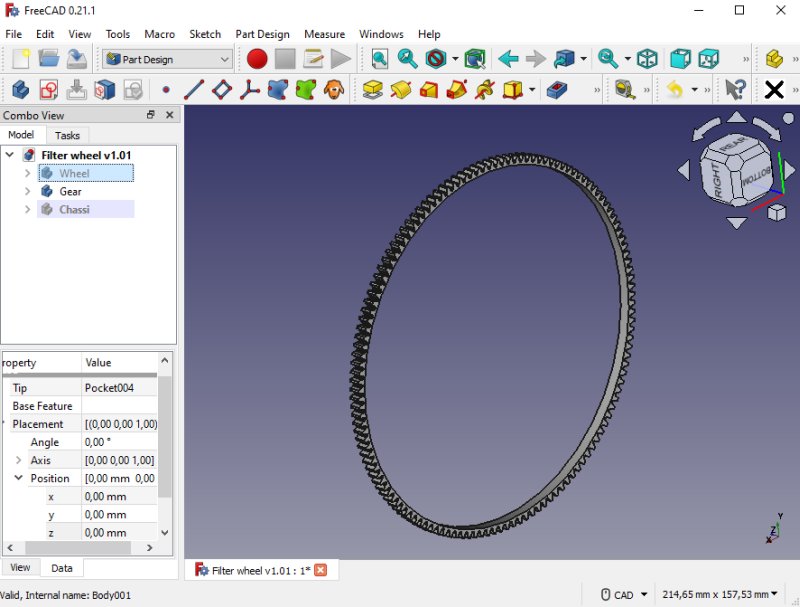

With a 3D-printer and a 3D CAD software it's easy to design gears, this gear will be fused together with the filter wheel at the rim. This is just a test how to design a gear. Set the number of teeth to 130 and the module to 1, the equation is: Module = diameter / (number of teeth + 2). It gives a gear with 132 mm outer diameter, average teeth diameter 130 mm. Stepper motor 1:

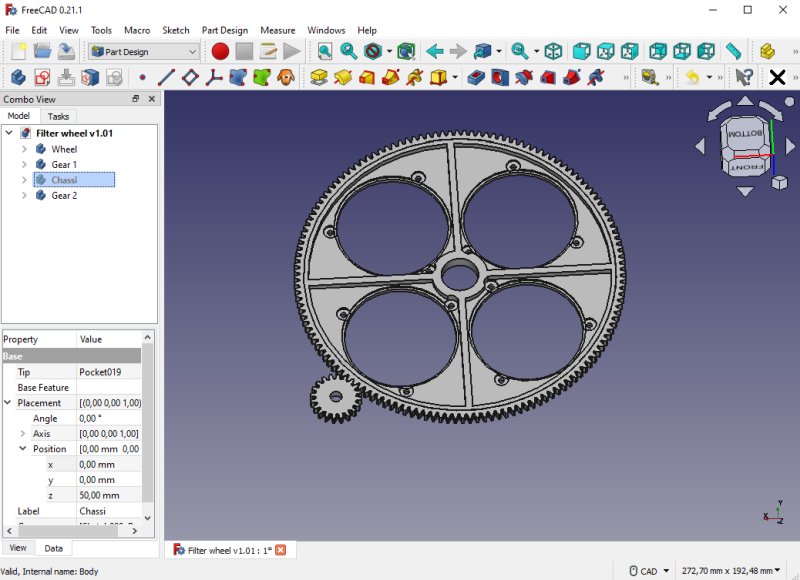

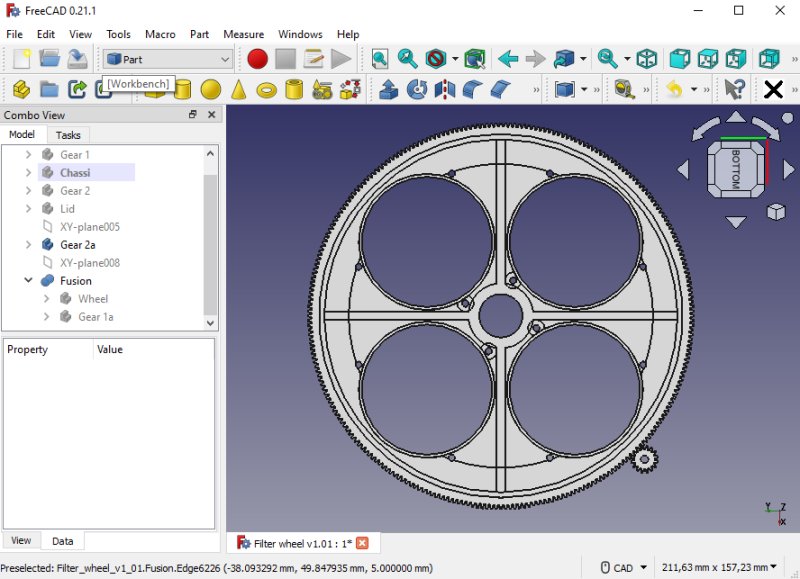

From the info above I go to the next step, a gear for stepper motor 1. Now when I know which stepper motors I will use I can fine adjust the gear's size. I have increased the big gear to 140 teeth, the small gear has 20 teeth with a shaft hole of 5 mm.

Between the gear's teeth's top and the walls of the chassi it's about 2 mm. Good to have some extra room if I have to fine adjust the size of the gear. Stepper motor 2:

For the stepper motor 2 which already had a gear with a small modulo, 0.55 I designed another gear. 256 teeth at module 0.55, the small gear has 16 teeth, a gear ratio of 1:16. I have my doubt if it's possible to 3D-print a gear with these small teeth. 3D-printing:

I setup the printer to:

The result is fantastic, the gears are almost perfect. One drawback of using a brim was that it was very difficult to get rid off, it's the teeth that cause this. As it's now the lower part of the gear is all the way to the bottom layer, maybe I can move it 1 mm upwards (and enable support) and get better result. Alternative is that I add a flange of 1 mm at the bottom.

Here I have tried to get rid of the brim, normally when it's a sharp edge it's not any problem. But now it get stuck between the gears. The teeth's shape looked much better before I tried to remove the brim.

If I let the motor's gears be above the area where the brim is it works well. The gears' teeth match each other very well.

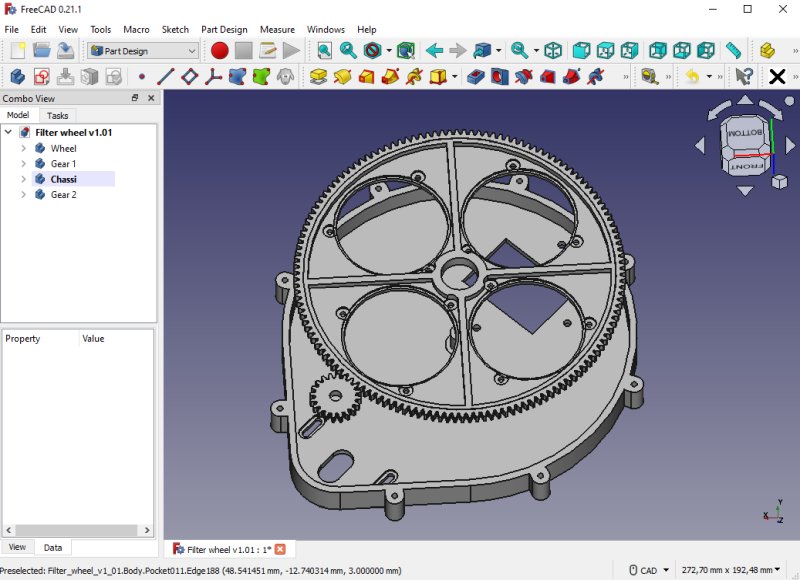

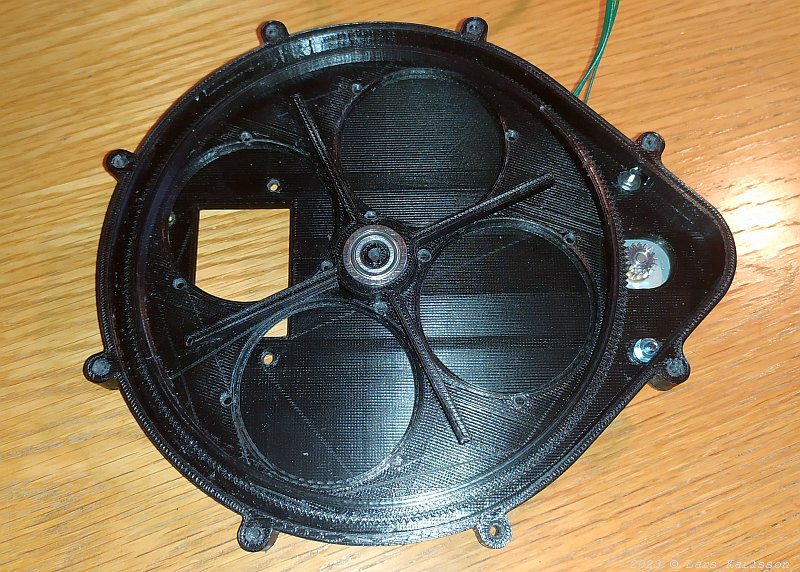

The filter wheel and motor installed in the chassi, looks good to me.

I can see that the wheel isn't perfect circular, I think it has to do with the big holes for the filters. It could be a problem with these small teeth, module 0.55. Better to increase the module from 0.55 to 1.0 and replace the stepper motor's 16 teeth gear.

|

|