|

Advertisement / Annons: |

My friend Lars B's projects |

Contents:

Note: |

1, Casting parts for a mount, part 1:Lately I got a new astronomy friend. I had a problem to solve and needed some help with machining works. Then I came in contact with Lars B, yes he has the same name as I have. He found it interesting and helped me with the work that I needed to be done. Now I got an insight in Lars' life and all his ideas, he likes to manufacturing his parts from scratch, and then I really mean from the really basic. His latest project is to build an oven, with that he could cast aluminum, brass and maybe glass in the future. I talked to him and told him this is fantastic, shouldn't we write down something and show others what can be done with some work and fantasy ? Yes he said and here you will get a glimpse into the fantastic work and maybe get ideas what you can do yourself. Shaft and worm gear for a small mount:Lars B has earlier built a mount with plastic parts from a 3D printer as an experiment, now he shall take it up one level and do it in metal.

Lars B's comment:

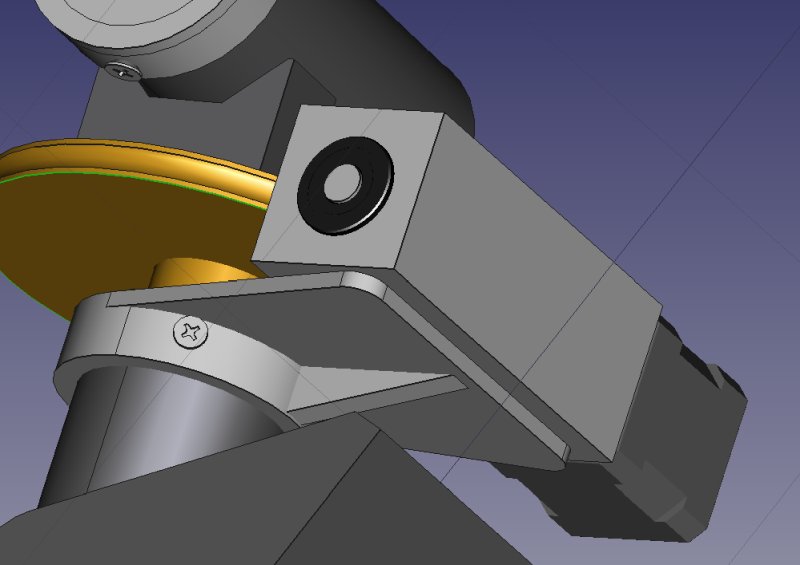

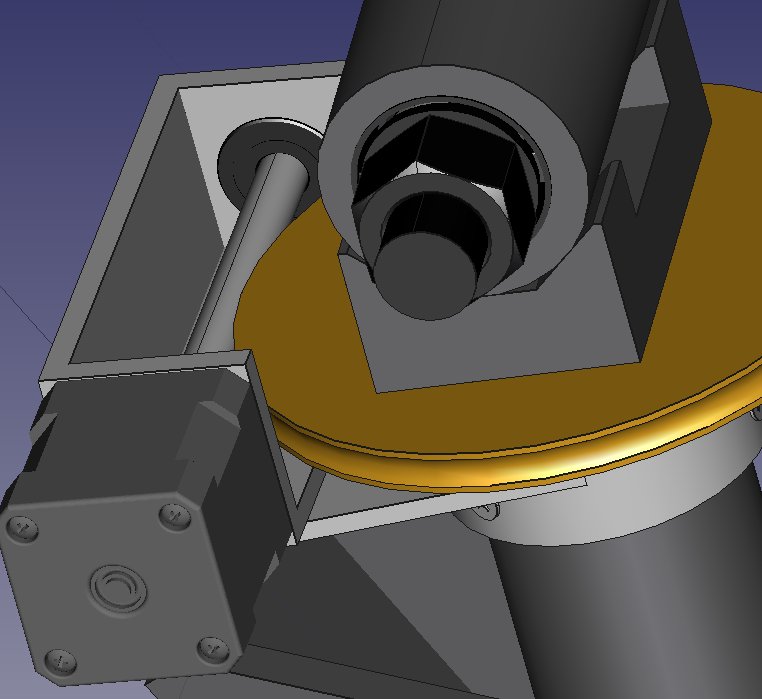

Lars B's comment: Lars B has done some CADs of his project.

Lars B's comment:

Lars B's comment: With a RA shaft made by a professional workshop Lars built a holder for the DEC shaft that sit in 90 degrees on top of the RA shaft. A cone at the end of the shaft make them fit perfect together, the aluminum holder is of course casted in Lars B's new oven.

Lars B's comment:

Lars B's comment: The plan is to have a worm gear reducer, to that a bracket is needed that hold the worm screw. Also this one is casted in the oven.

Lars B's comment: Worm gears with big dimension and many teeth are very expensive, Lars B has succeeded to cast a brass block to machine to a worm gear. It's very important to not get any pores in the material.

Lars B's comment:

After some work in the lathe and milling machine the worm gear has got teeth.

Lars B's comment:

|

|