|

Advertisement / Annons: |

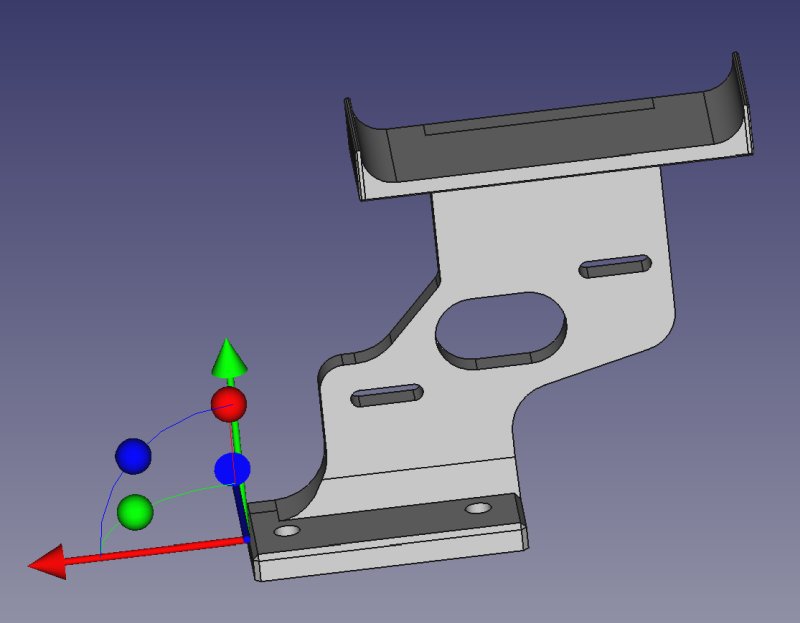

3D CAD drawing:

|

Contents:

Note: |

2, CAD bracket version 2:Info:With the first pulleys printed I can start measure more exact how the motor bracket should be designed. I have now started with version 2 and I print it out to do some test. Bracket version 2:

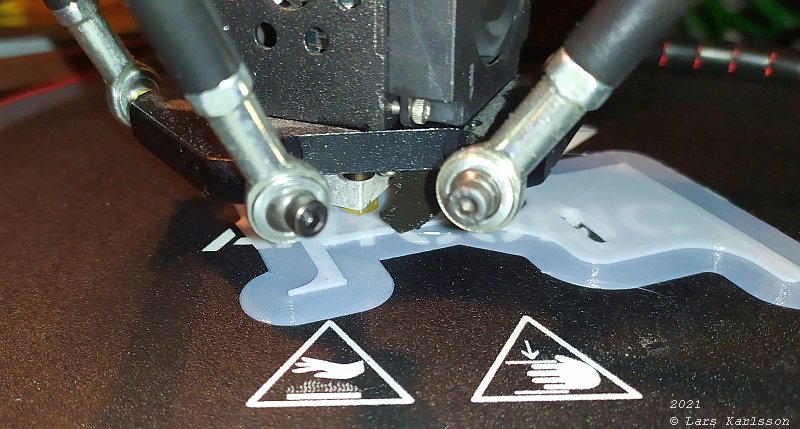

I have adjusted some of the dimensions. On top I have added a holder to the stepper motor driver. Printing the motor bracket:

This time I checked carefully that all are in correct position and no problem with unconnected modules. This bracket doesn't need high precision and I print with 0.2 layers. It should only take 2.5 hours to print. It's very important to have all the holes already in the drawing that is needed. If you don't print a 100% fill it's not possible to make any holes afterwards, there are no reinforcements added where there are no holes, I plan to print this with 40% fill.

After 2.5 hours I got this, looks really good.

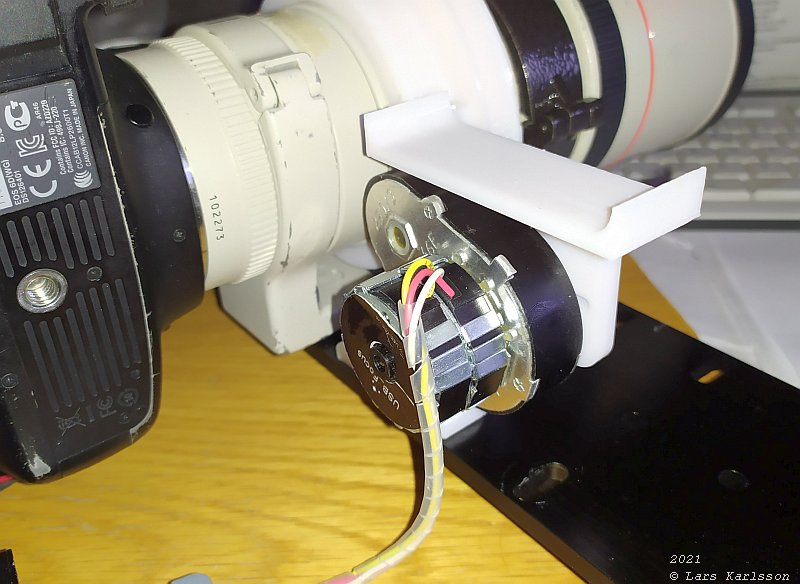

Threading the holes for the M6 screws, no need of drilling.

There are some details I missed, but can use it for testing.

The slit for the motor axle was offset about 15 mm, I missed that.

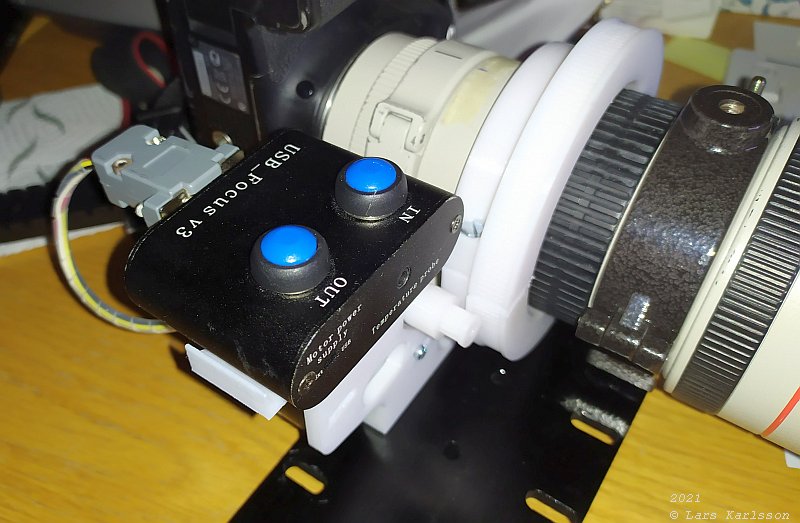

The driver device in place with it's In / Out buttons.

Now I have to fine adjust the positions of the slits and holes. I shall also work a bit more on the holder to the control box. |

|

|