|

Advertisement / Annons: |

Macro photography

|

Content:

Note: |

7. New high precision macro sledI can already feel at 3 times magnification that my macro sled doesn't have the precision that is needed. I have started to design a new in CAD. This one is also prepared to be motor driven. A stepper motor can with high precision move the sled. Maybe good enough for ten times magnification and focus stacking. |

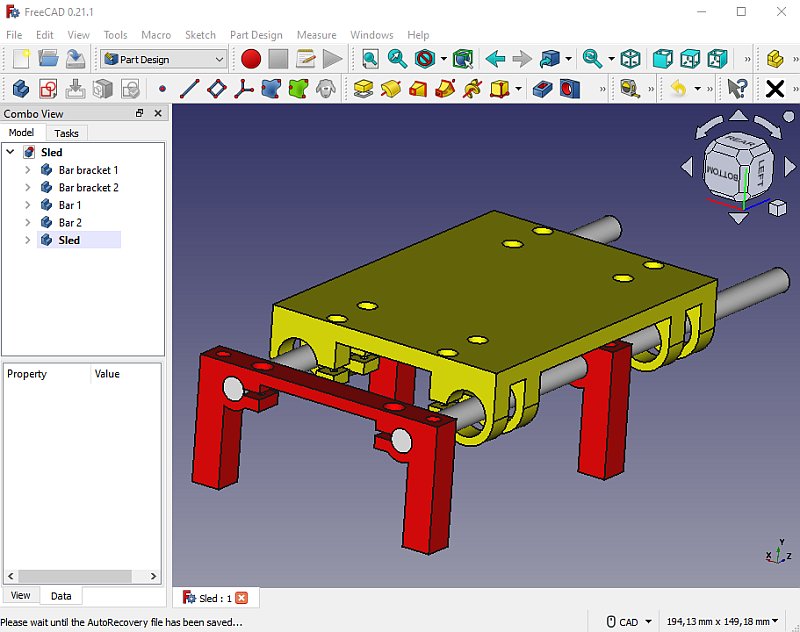

CAD design of a new high precision macro sled:

This is my fist idea how a new macro sled can be designed. It has a stroke of 90 mm and four linear roller bearings. A big flat top surface where I can attach other devices. It can be another sled that moves the object sideways. A rotator and height adjuster.

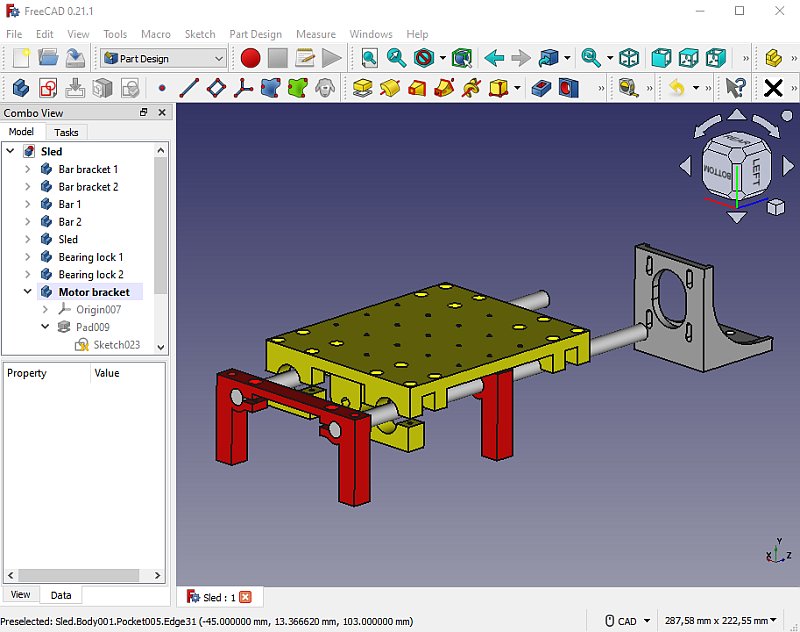

Adding more details to the sled. The gray bracket in the background is for a NEMA 14 standard stepper motor. What's missing is two limit switches, stop the sled to crash into other brackets.

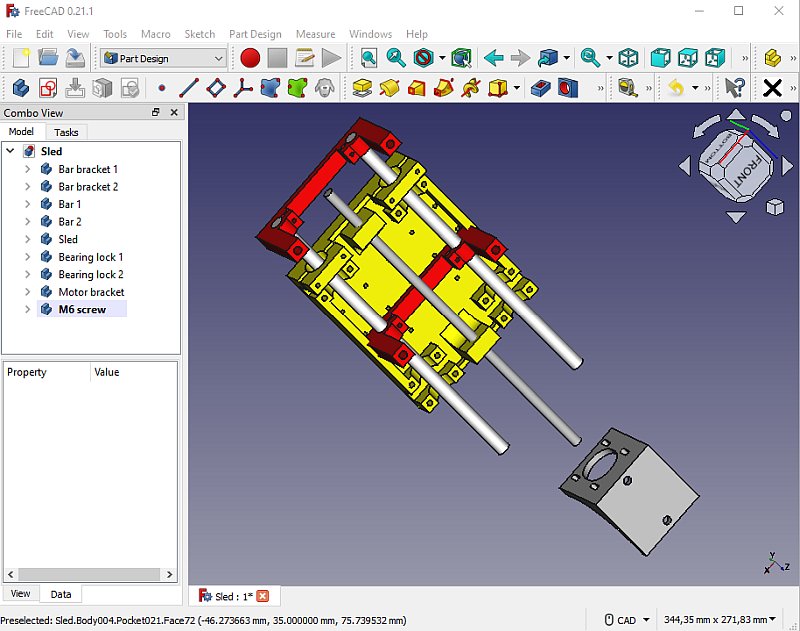

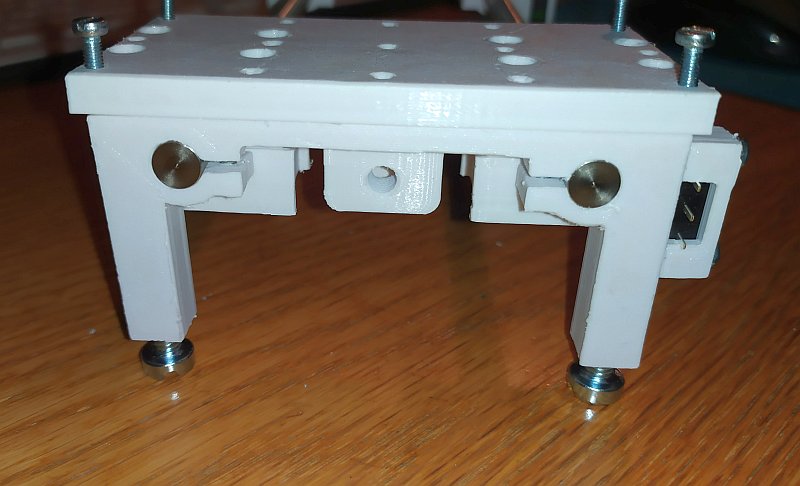

From below. 3D-printing parts:

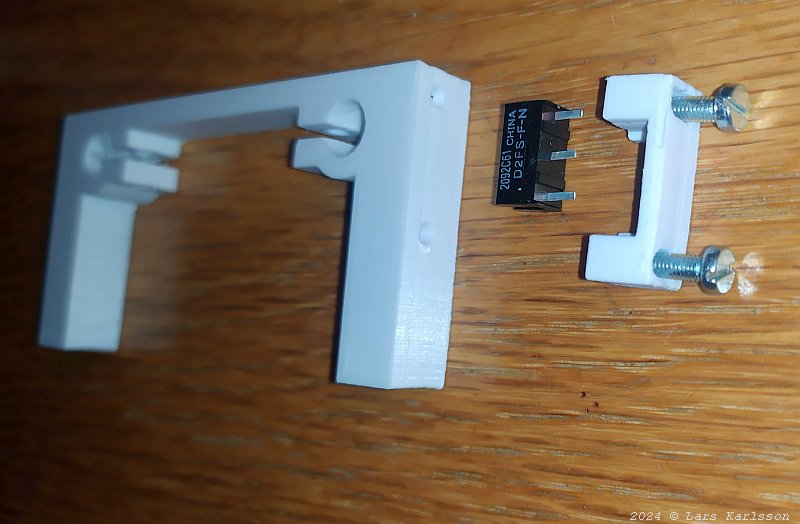

I have now started to 3D-printing the different parts that I have designed. It's the steel bar brackets and the limit switch brackets.

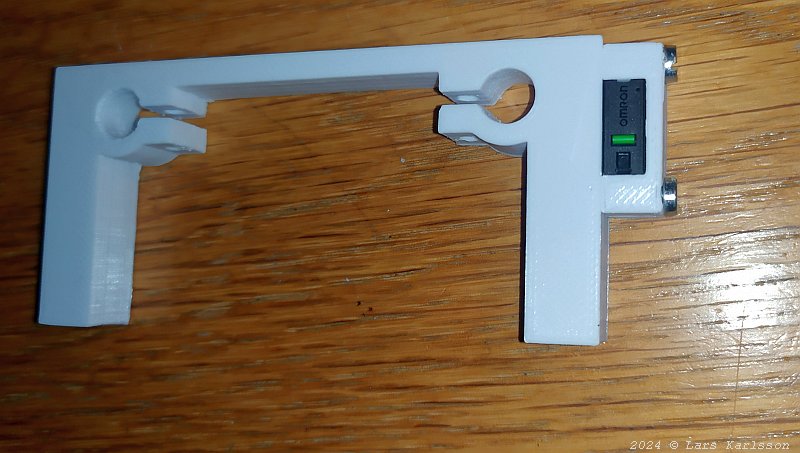

The limit switch is adjustable with the two M3 screws.

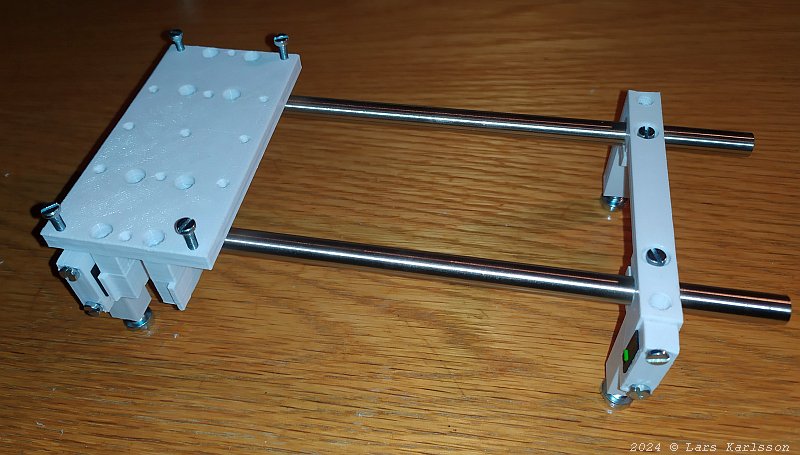

With the steel bars installed. Every thing fits perfect, strange, they normally never do that.

The sled in place, waiting for the linear bearings. Maybe I don't need four of these linear bearings, if only two I can built it much more compact. Further test will show how many needed.

The limit micro switch in action. Increasing the stroke:

In an attempt to increase the stroke from what now a little bit limited 65 mm I change the design of the sled. Reduce the linear bearings from 4 to 2 and could then shorten the bed. Whit this I now have 125 mm stroke. Not as stable as before but I hope it will be good enough.

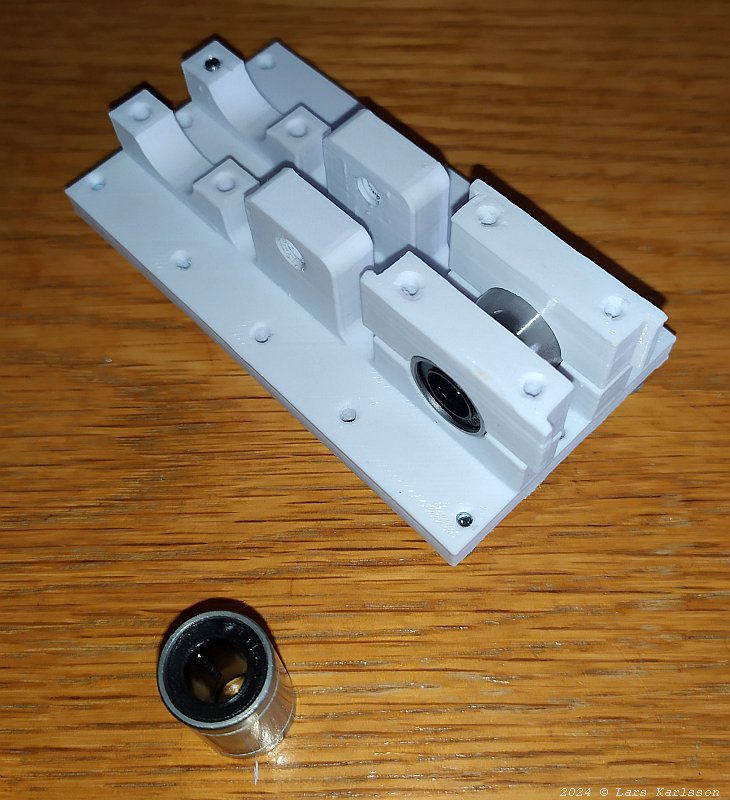

The center hole is threaded M6 and here the screw that move the bed will be inserted. 1 mm correspond to 0.5 mm move. A stepper motor has 200 steps per revolution. That is 2.5 my per step and it can always be micro stepped.

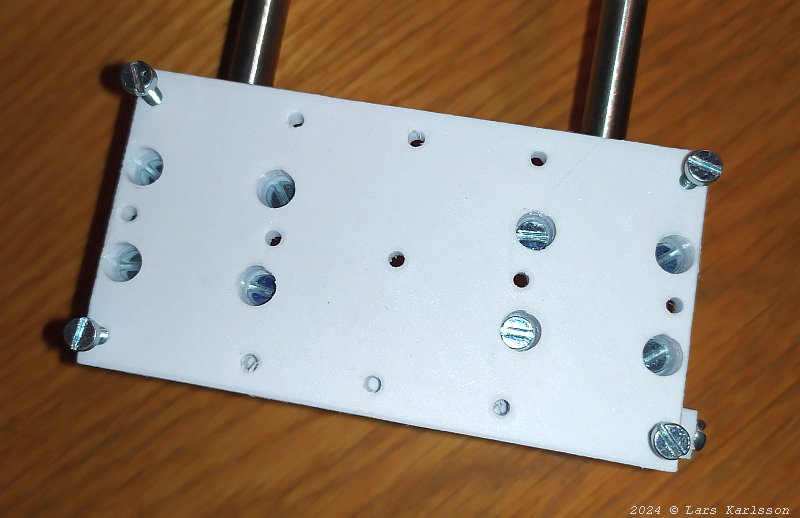

The top of the bed where I can attach different devices. The small holes are threaded M3. Manual control of the position:

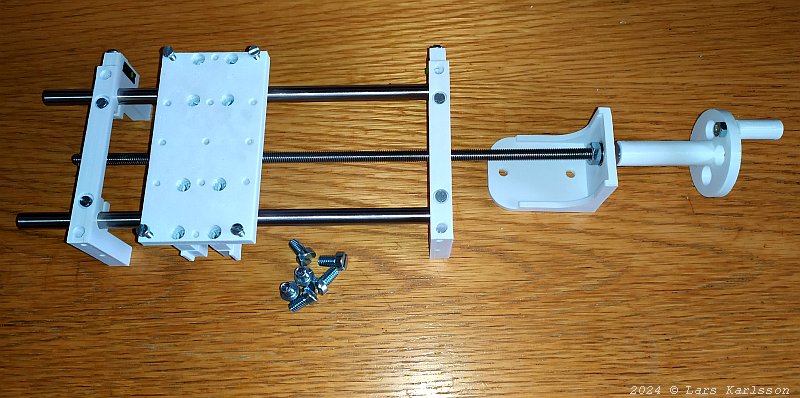

Before I build the stepper motor version I will have it manually controlled. I have designed this little kit.

The linear roller bearings has arrived, fit well in my bracket. There are two 8 mm diameter of them.

Assembled together, the stroke with this setup is over 120 mm.

Installed on the macro rig. One turn of the well moves the object 1 mm. It's easy to do 1/8 turn for each photo, 125 my. Later I replace the wheel with a stepper motor and a control unit. |

|

|