|

Advertisement / Annons: |

Macro photography

|

Content:

Note: |

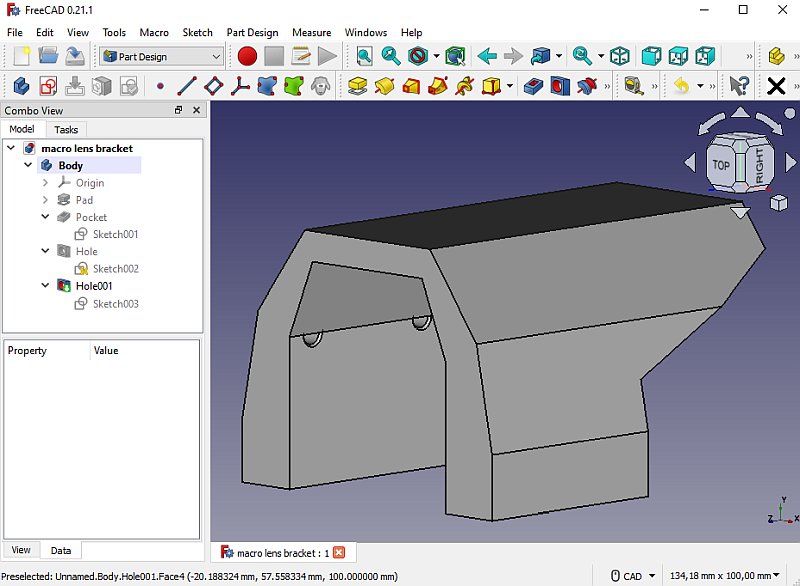

3. Lens bracketBracket design:The lenses must be attached to a stable bracket that do not introduce any vibrations. I 3D-print that bracket. To get some ideas of the design I use my old bracket as a template. |

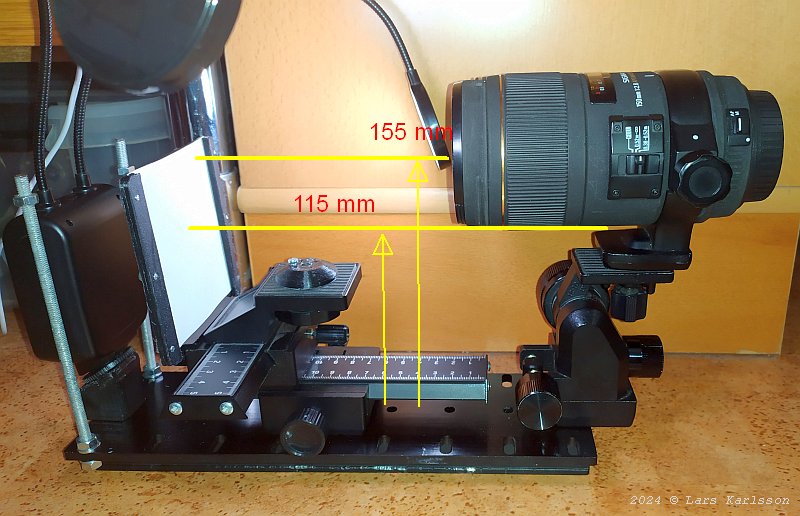

Height of optical axis:

After some measurement I found that the optimal height of the optical axis is 115 mm above the ground. My old bracket hold the lens' optical axis at 155 mm height. A bracket with a height of 60 mm would fit well. CAD design of lens bracket:

It's like a tunnel, through here the sled can slide in.

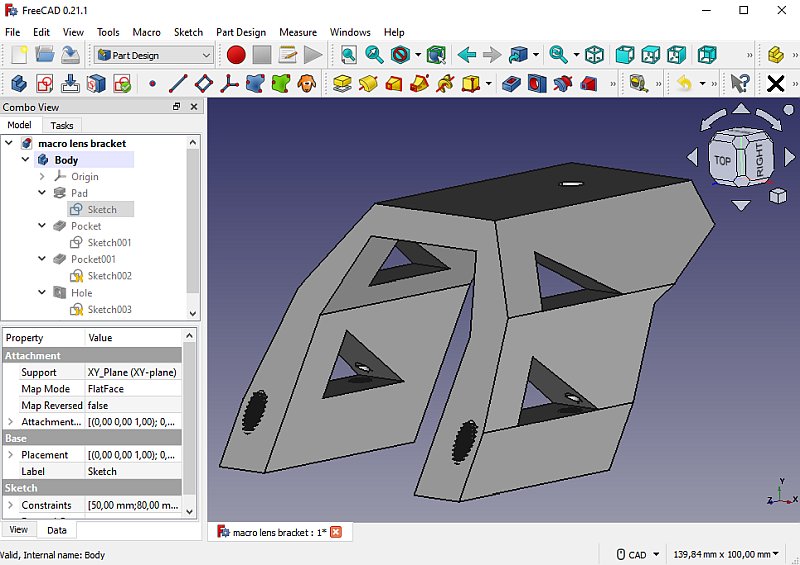

After some tweaking of the details I got this.

3.5 hours and the 3D printer delivered this. Very low weight and still very stable, printed with 15% fill factor and PLA filament.

The sled can slide in under the lens bracket. The screw holes let the bracket to be moved in 35 mm steps. It's built to be flexible, you never know what lens and camera to be used later. Lens support:I noticed some up/down vibrations at the front of the lens system. I have to construct some support for the front part of the lens system.

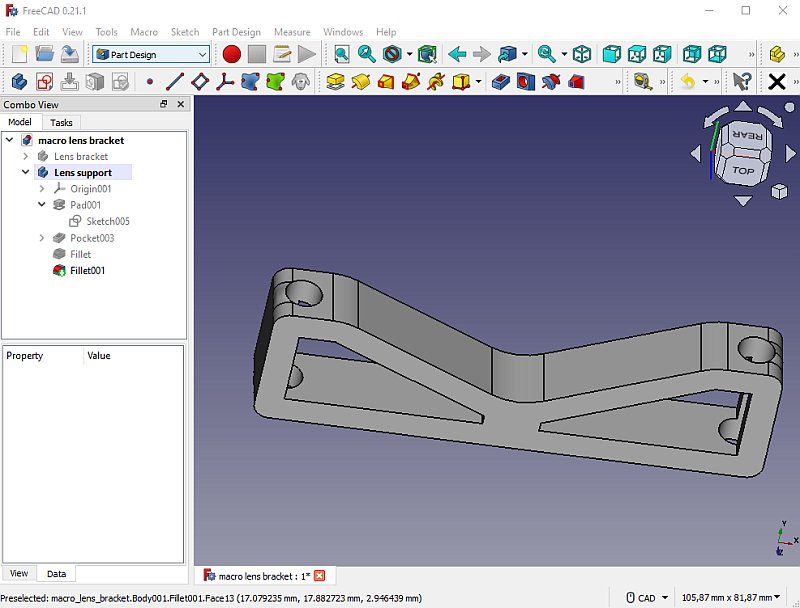

3D CAD design of the lens support. The main purpose of it is to cancel any vibrations that can occur. But it also hold the lens in correct direction, not swing left or right, if not enough I can make one more and place it on top.

Installed and adjusted to hold the lens in a stable position, stop any up/down vibrations. One more important thing, with this I can adjust the optical axis to be parallel with the sled. If it's not the object will move up and down when focusing. |

|

|