|

Advertisement / Annons: |

My astronomy project:

|

Content:Ideas about 3D-print rack and pinion gears:

Related projects:

Note: |

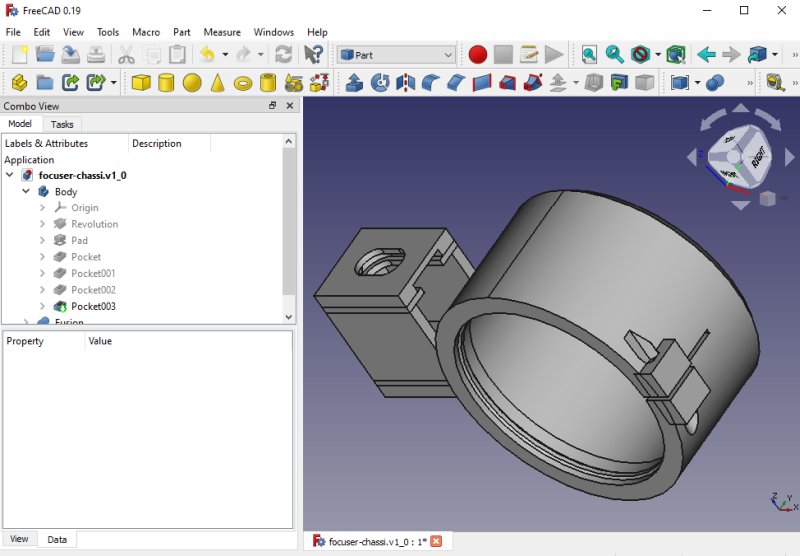

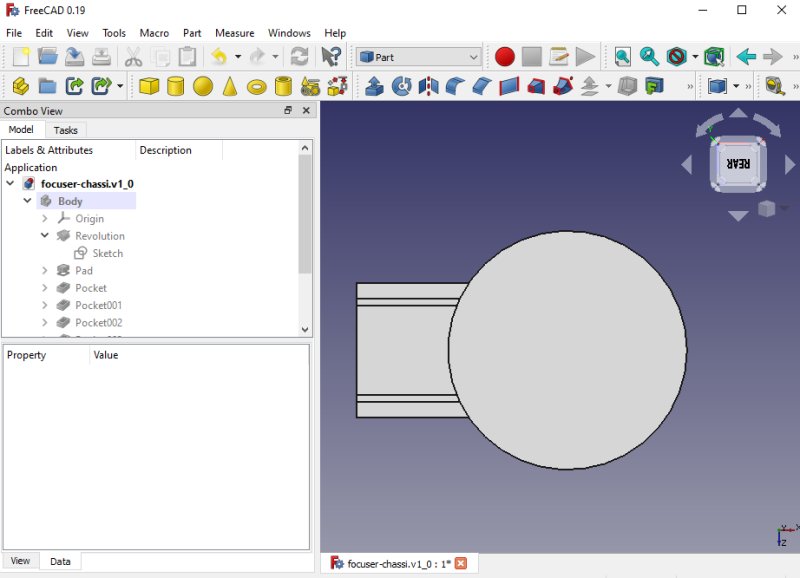

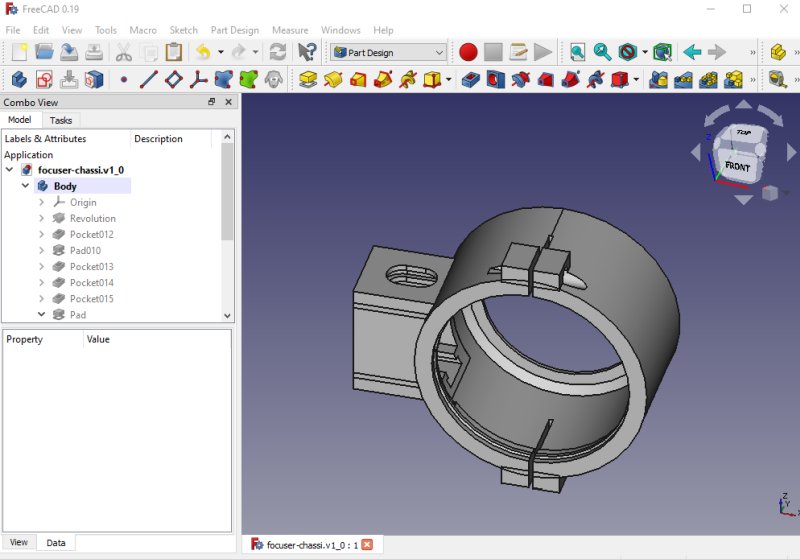

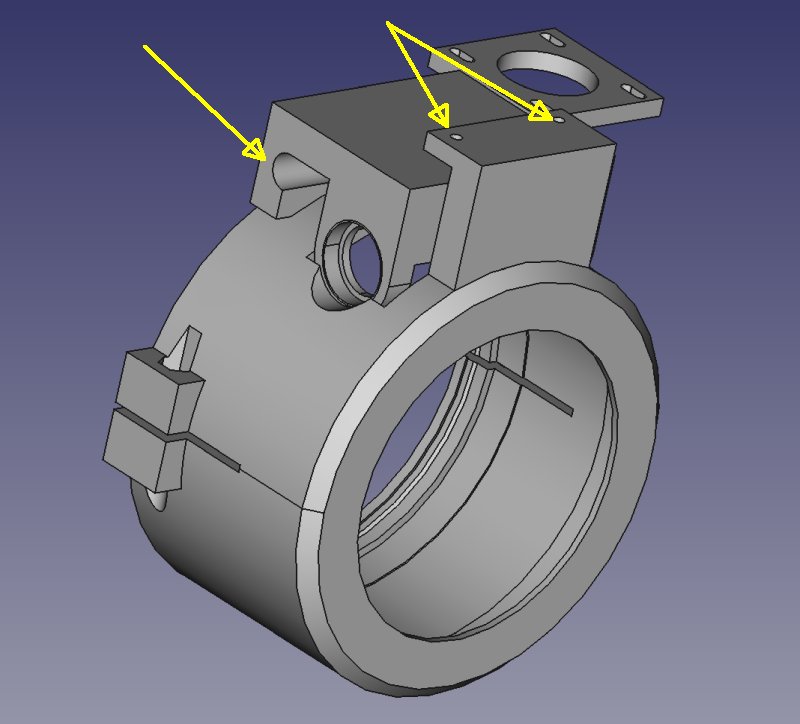

4: 3D CAD focus shaft holder and focus chassiIt has come to the part where I design the focus chassi and join it together with the focus shaft bracket. I don't know exactly about the details, but I try to do a prototype as close as a functioning focuser I can get.

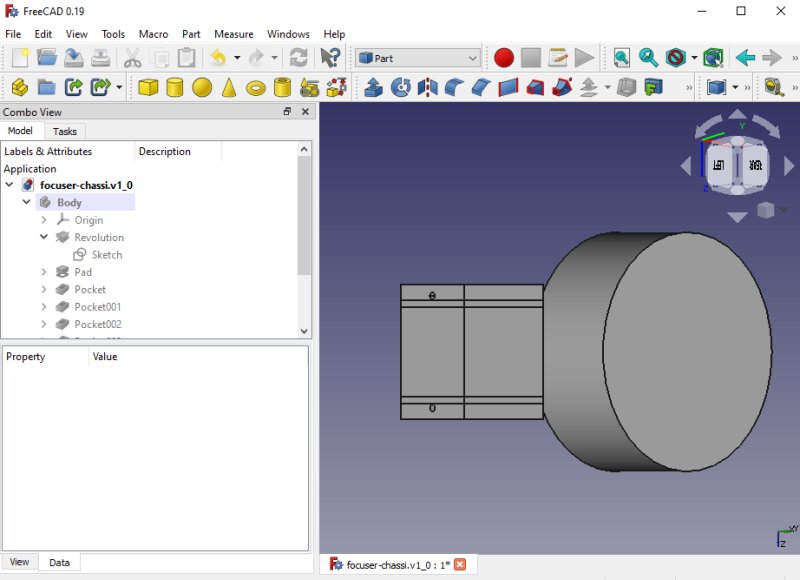

Next thing is to fuse this focus shaft holder together with the focuser chassi.

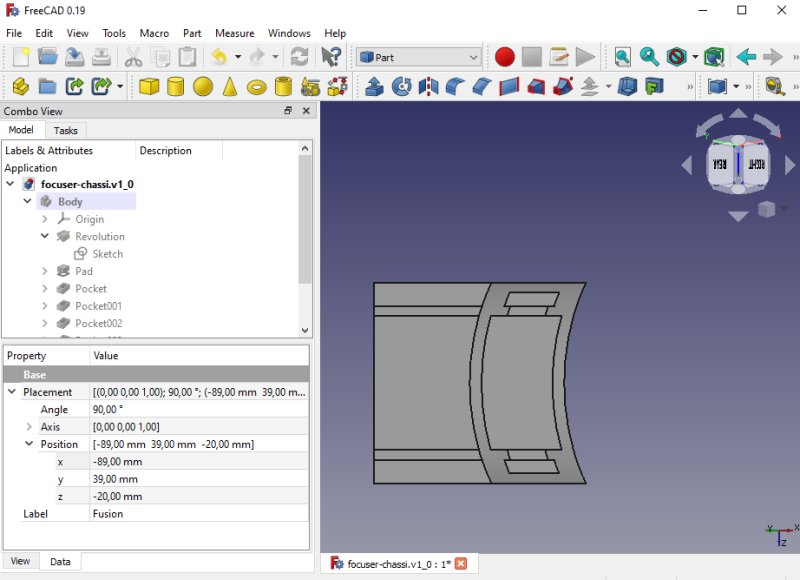

I must have a hole in the focus chassi to let the focus shaft holder to slip into. I used the Pocket Toll in Part Design to do that.

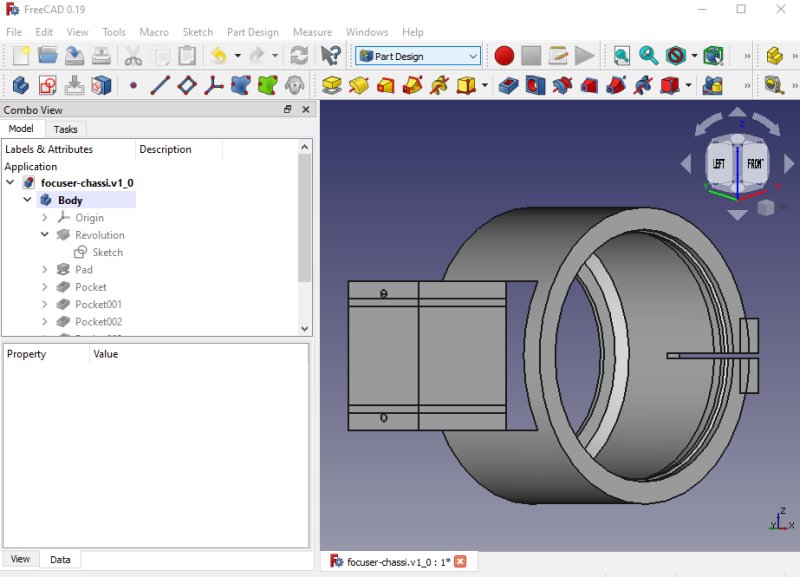

Adjust the position of the focus shaft bracket in front of the rectangular hole.

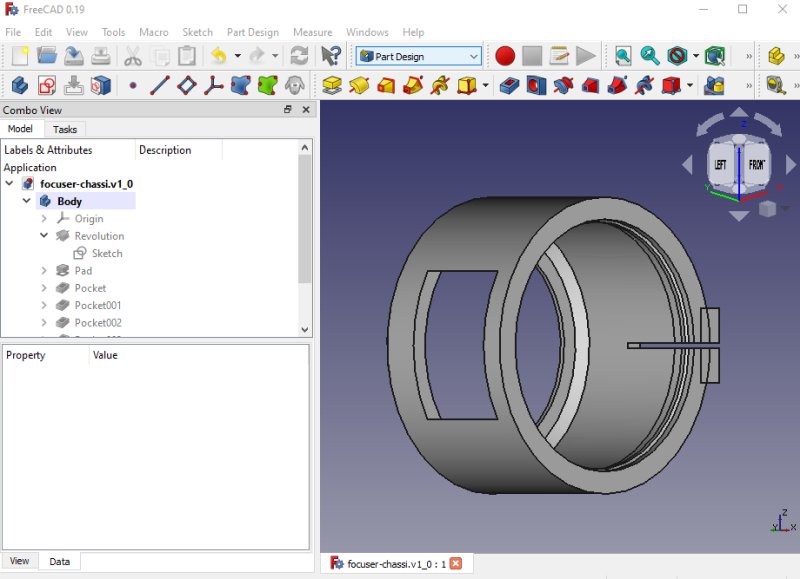

The end of the bracket need a curved shape to fit the focuser chassi. To solve that I work in the Part mode and add a cylinder.

Adjust the size and position of the cylinder where I want to have the curved shape.

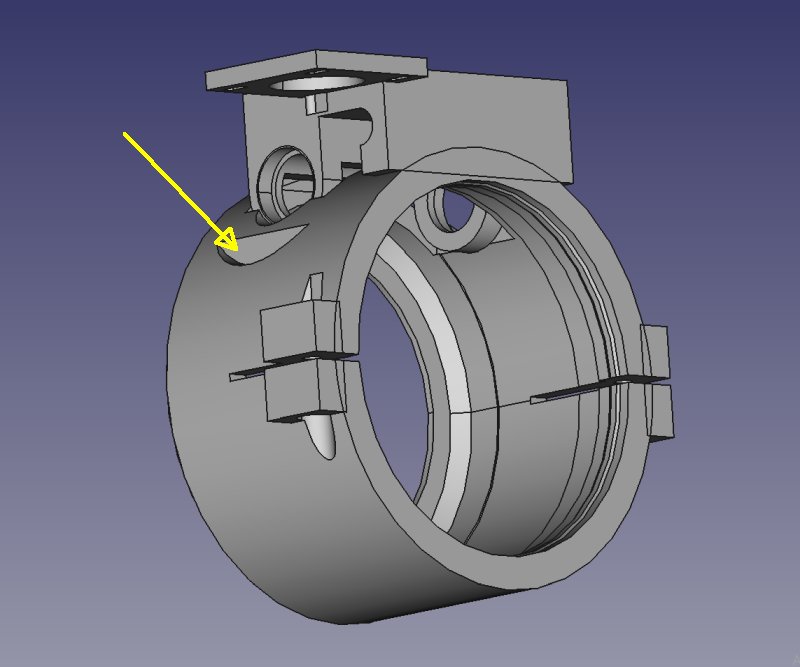

Subtract the cylinder from the bracket and viola ! The Part mode have caused me trouble earlier when I want to print it, maybe I later have to redesign it and use the Part Design mode instead.

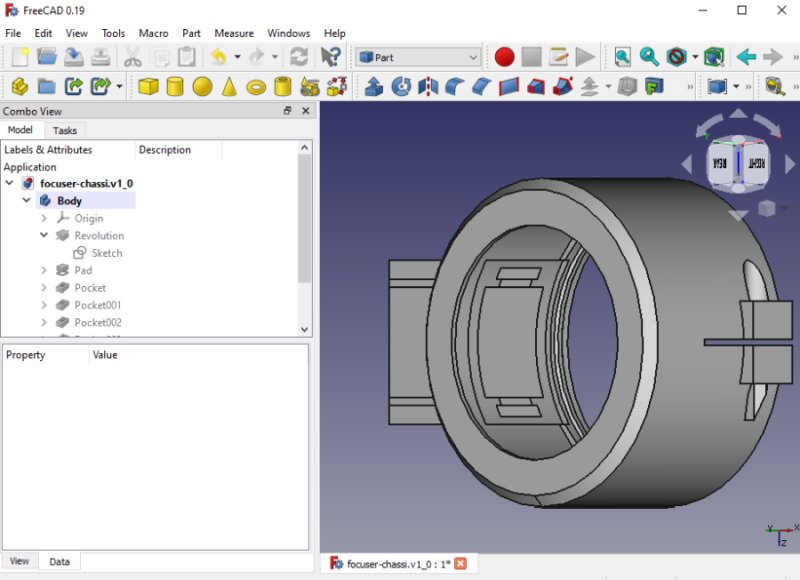

Let the bracket move inside the focus chassi. Looks very good to me.

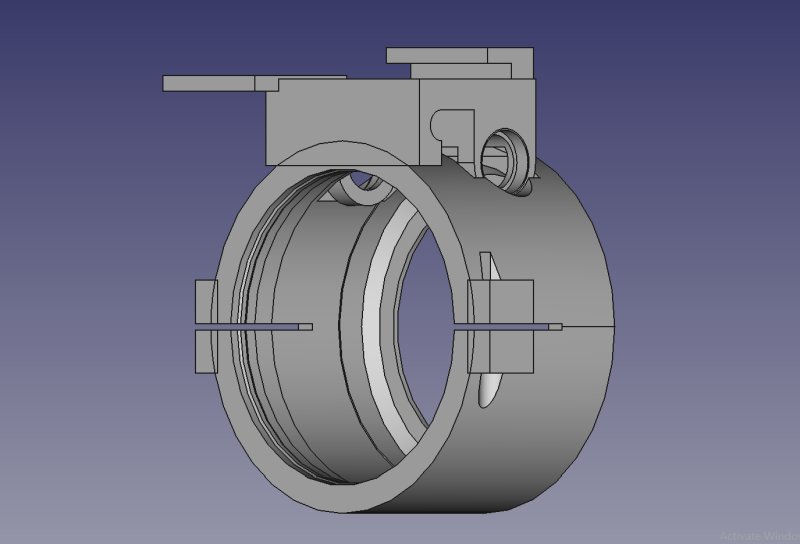

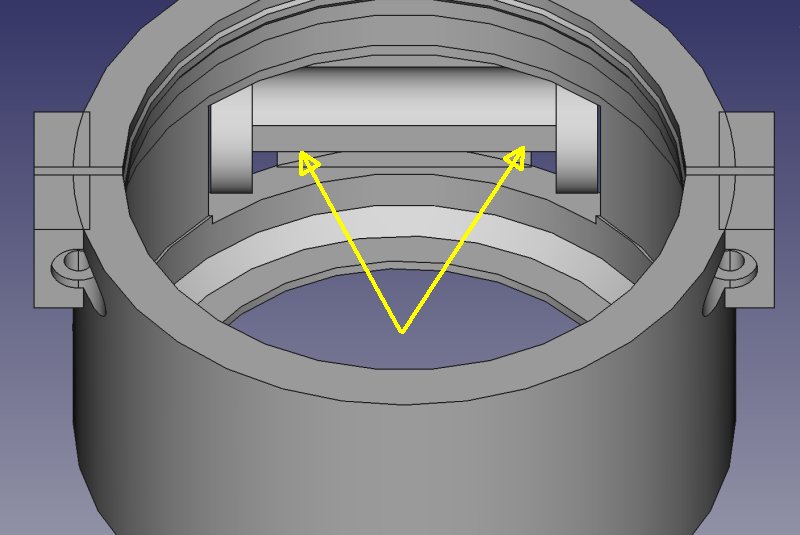

Another view of the focuser. The two roller bearings that hold the focuser shaft will slide into the slits. With the two adjust screws (on the backside) the force of the shaft against the rack can be adjusted. Not too different that the earlier friction coupling worked. |

At the right side the roller bearings are placed that support the focuser drawtube. It can be a trouble to have the slit between the support of the roller bearings. I redesigned it and placed two new slits symmetric on each side. Just another two hours of CAD. Now I need a pause to think over the details to get them correct. This focuser will be very complicated to 3D-print, it needs a lot of supports. And it needs a stepper motor bracket implemented too. Second version of focus chassi design:Making a design with the Part tool isn't the best, I have redesigned it and now use the Part Design tool instead, all done in FreeCAD.

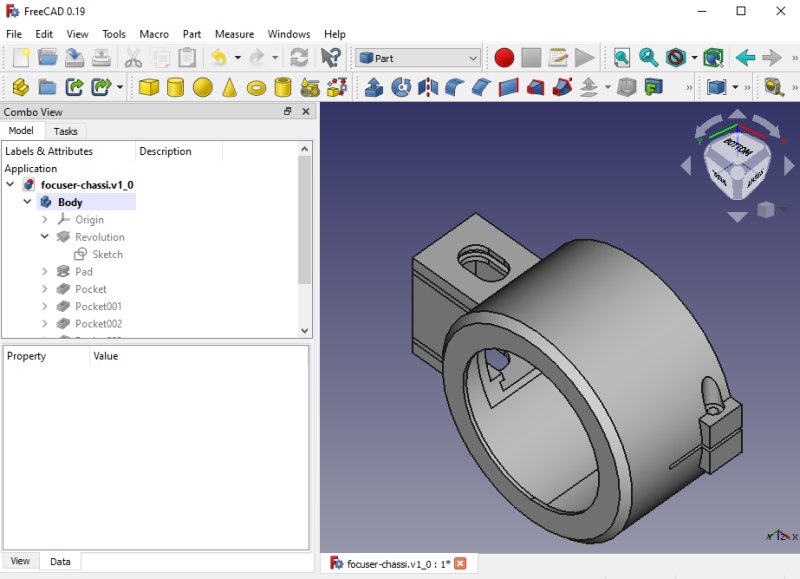

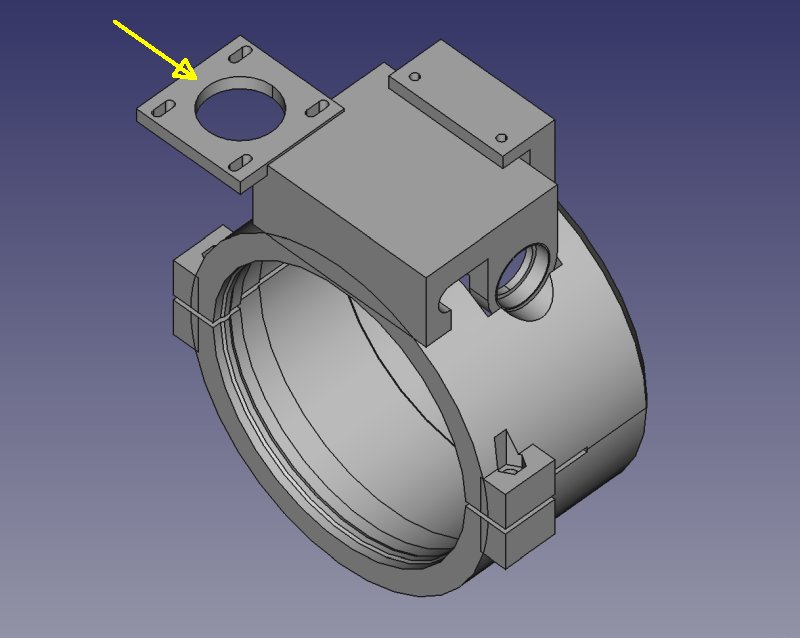

The top part that hold the gear to the rack and pinion is now totally new. Instead of the sliding roller bearings it's now a construction that flex.

I have also add a stepper motor bracket, it's NEMA 17 standard. Not perfect yet, it protrude outside the focus chassi which make it difficult to print.

On this side the worm gear will sit on the focuser shaft. The worm gear have a diameter of 45 mm and an opening had to be done to make it fit.

To make the force that the gear act on the rack the bracket flex at the edge to the left. On top two screws are used to set the force.

Inside of the focuser chassi, at top where the focuser shaft with its gear is placed.

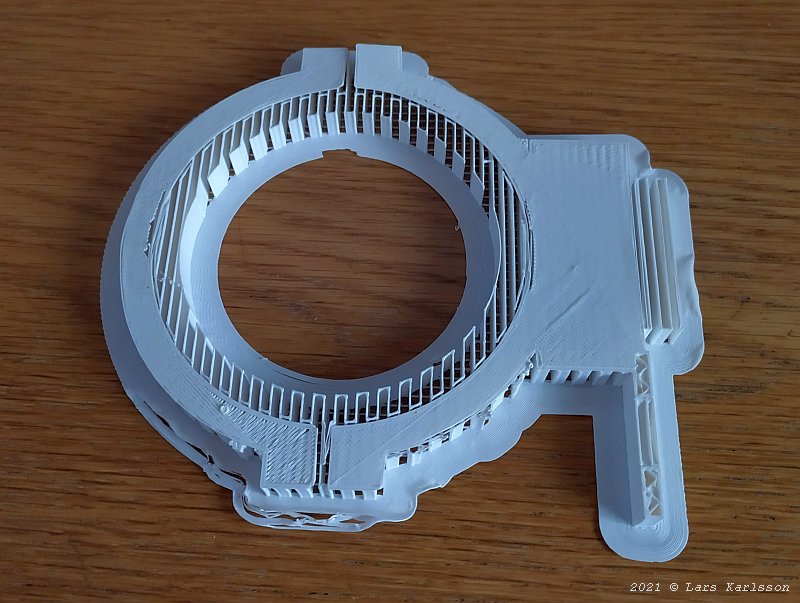

My first attempt to 3D-print a prototype of the focuser chassi. Didn't work very well, the printer stopped during the work because of unstable nozzle temperature.

|

|