|

Advertisement / Annons: |

My astronomy project:

|

Content:Ideas about 3D-print rack and pinion gears:

Related projects:

Note: |

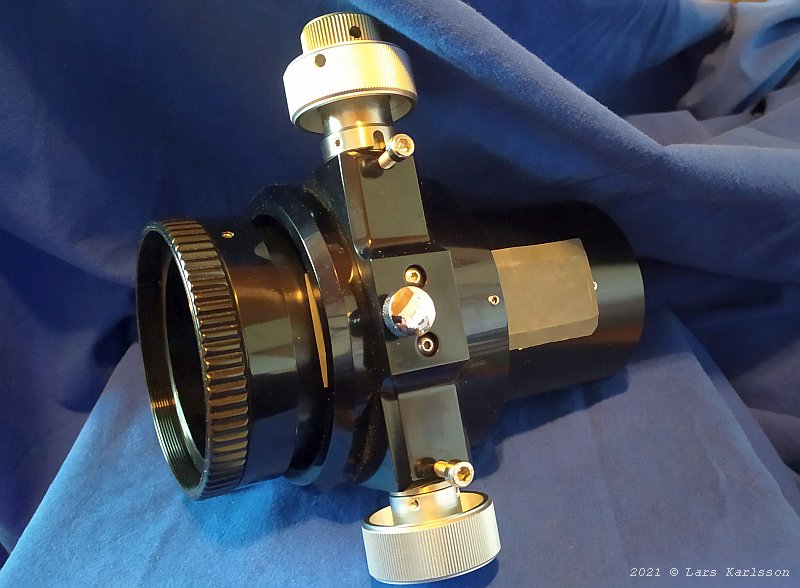

2: How to implement the rack & pinion into the focuserNow when I have tested to 3D-print the rack & pinion gears with success I move to the next step. How to implement it into the 3" focuser I have. I could of course bought a new focuser which already have a rack & pinion and a stepper motor. But it had cost a lot of money and it's more fun to construct something by myself.

I removed the focuser from the telescope, not the first time and now it doesn't take very long time for me.

The other side, the grey part to the right is the steel friction plate, to increase the friction I have glued a sandpaper to it. It works well with no slipping but have to replace it with a new sandpaper once a year.

The holder of the focuser shaft, the roller bearings are set under force by the top outer screws to have enough friction to not slip.

Now when I have the parts dissembled I measure the weight of them. The focuser draw tube weight 0.75 kg, that was a lot more than I thought.

The 3" field flattener weights 0.55 kg. Together 1.3 kg, to that I have to add the camera, about 1.5 kg, still no filter wheel or off-axis adapter with its guide camera. It's not hard to understand that the friction coupling slip sometimes.

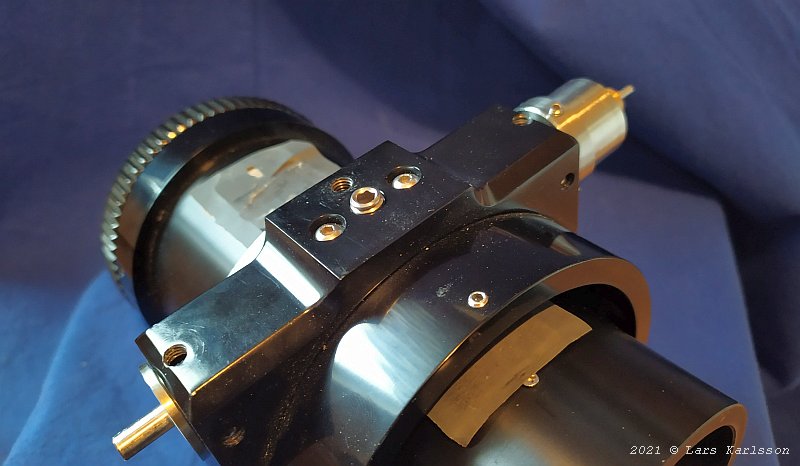

Inside the focuser, the four roller bearings that the focuser draw tube ride on. The force acting on the steel friction plate also hold the focuser draw tube in correct position. With a load of 4 kg It must have a high force to not come out of position.

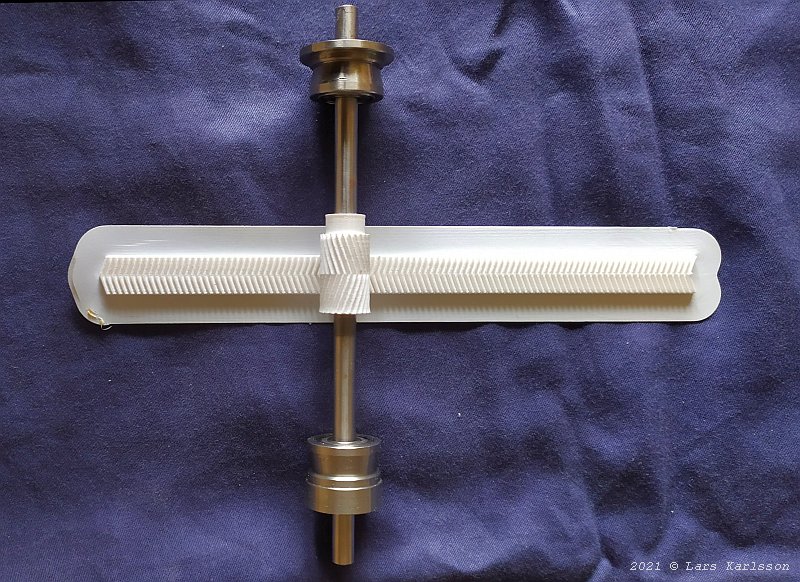

The draw tube and its holder. In my first attempt to implement the rack & pinion gears I try to keep these parts.

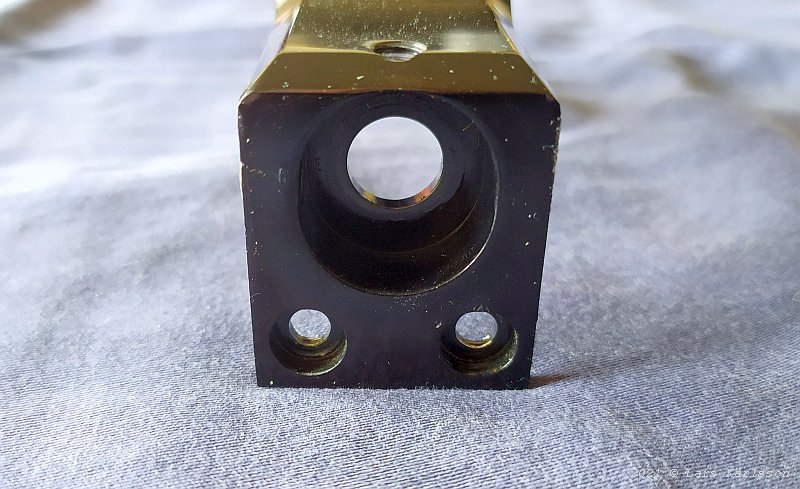

The hole where the focus shaft was placed, now in someway I have to fit the helical gear inside this hole. It looks impossible. |

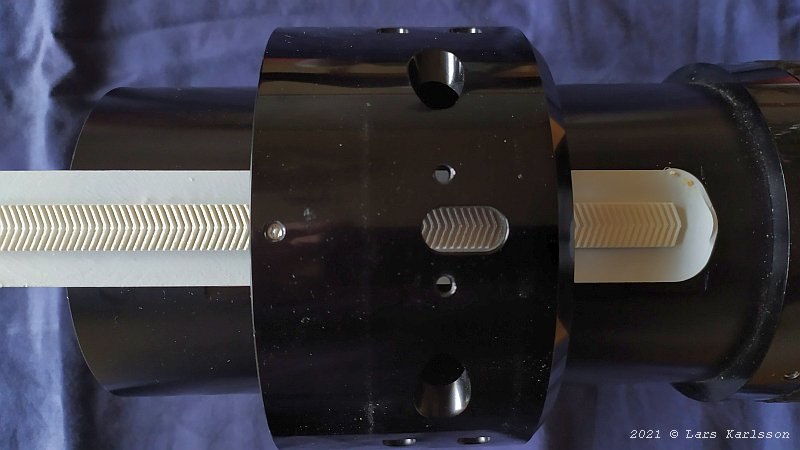

With the rack of module 0.5 mm put inside.

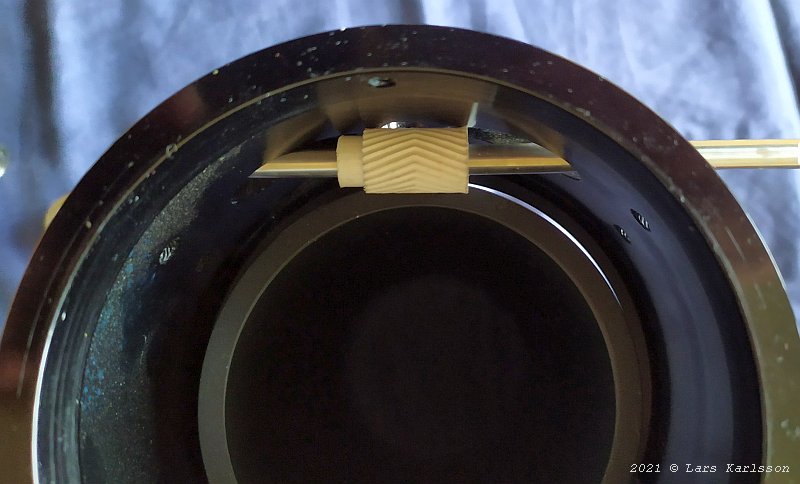

Top view of the rack and focuser.

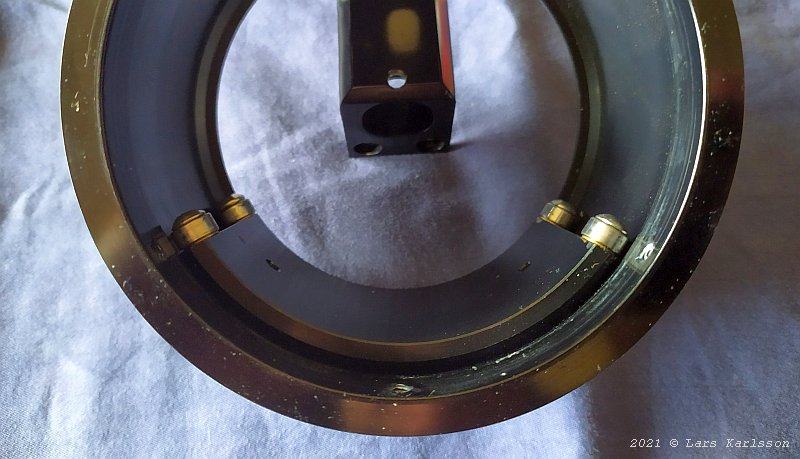

At bottom the friction steel plate and above the shims, altogether 3 mm thick. The size of the steel friction plate is 114 mm long, 26 mm wide and 2 mm thick. The two small holes are 90 mm apart, two M2 screws hold it in place.

The old bracket that hold the focus shaft and set it under tension.

One of the ends of the bracket. The elongated hole is where the roller bearing sits. When it's adjusted up and down with the top screw the force on the friction shaft against the steel plate is adjusted. Even if I can reuse this part I plan to 3D-print a more advanced bracket. It should also hold the stepper motor and the external gear box.

The focus shaft with the prototype helical gear mounted. Looks good but next version of the rack will be much wider. When wider the helical gears works better, a lot of teeth is in contact all the time which makes a smother move.

Helical gear installed into the focuser, here is very limited space. With fewer teeth the helical gear gets smaller, but also the strength of it decrease. I can mill the focuser house to get more space. But should I do that to a very expensive APO refractor ?

|

|