|

Advertisement / Annons: |

A visit onboard the icebreaker Atle, 2019An exiting day when I got the chance to visit the icebreaker Atle |

|

In July 2019 there was an open day at the icebreaker Atle. Something that I don't want to miss, took a day free and got there. In the winter Sweden is a very cool country with thick ice on the seas. To handle this we have a couples of ice breakers. At Wikipedia there is more information about Swedish icebreakers (sorry, only Swedish)e:

|

|

They are rebuilding the harbor and it was not so easy to find the walkway to Atle, but here it is.

They only stay here today and the only chance for us who living in Stockholm to do a visit. In the middle you see the helicopter landing platform. They call the ship an airport.

Aft deck. At Wikipedia there is more information about the icebreaker Atle:

The mechanism that hold the towing cable in correct position.

Machinery for the tow cable.

Atle was built 1974 and is 45 years old today, but it's modern compare with the icebreaker Sankt Erik that I have visited earlier, Sankt Erik was built 1915.

It's written in Swedish, but look at the pictures.

Life boat, it can take up to 50 people. In the summer when the icebreakers are not needed they can be used for science work. This summer the icebreaker Oden is at the Northern polar cap and doing research about the environment.

The crew helped me and answer all the questions I had, now up to the bridge. |

|

Frihamnen is one of the old harbors in Stockholm that still is active. My father visited this harbor many times when he was out on sea during the 1940s.

The white building in the background is the Swedish stock exchange market. In earlier days it was Ford's car factory.

Outdoor bath, appreciated by the crew during hot summer days.

Captain's chair.

The view from here is excellent, 25 meters above sea level.

Steering wheel, but this is the spare steering wheel. Normally not used.

A traditional compass, used in case if the GPS system failure. |

|

One of the crew's cabin.

My friend told me, don't polish a ship's bell, it gives unluck.

Living room for the crew. The ship normally have a crew of 20 people but can also take 30 passengers.

Storm pump ? Looks to be something important !

Don't touch this handle !

Machine control room. Looks like the machine room I visited on the Birka passenger cruiser. Built by the same shipyard, Wärtsilä. More about Wärtsilä at Wikipedia:

What to do with this hand driven pump ? Maybe something to do with the fuel system.

Now we enter the exciting machine room. |

|

One of three pumps that control the ballast tanks. They can pump 600 m3 of water per minute and give the ship an angle of 14 degrees. A technique they use when they break thick ice.

Believe it or not but the engines are electric. Four motors with 5000 hp each. Power, 2 x 800 Volts and 3250 Ampere. Weight of each motor, 90 tons.

Water intake with ice filter, there are two of them. The water is mostly used to cooling.

Aft shaft with trust bearings. There are four propellers, two at the aft and two at the front. There is no gearbox between the motor and the shaft.

Shaft's connection to the electric motor.

Air compressors, they used compressed air (30 bar) when they start the diesel engines that power the electric generators. For critical machines there are at least two of them for safety reasons. |

|

Water separators, fuel and lubrication oil contains water that must be removed. Same principle as Gustav de Laval's milk separator.

Water pump in case of fire. Every crew member has education to handle fire onboard. After five minutes they must have started after an alarm. I got the same education in the Swedish Royal Navy.

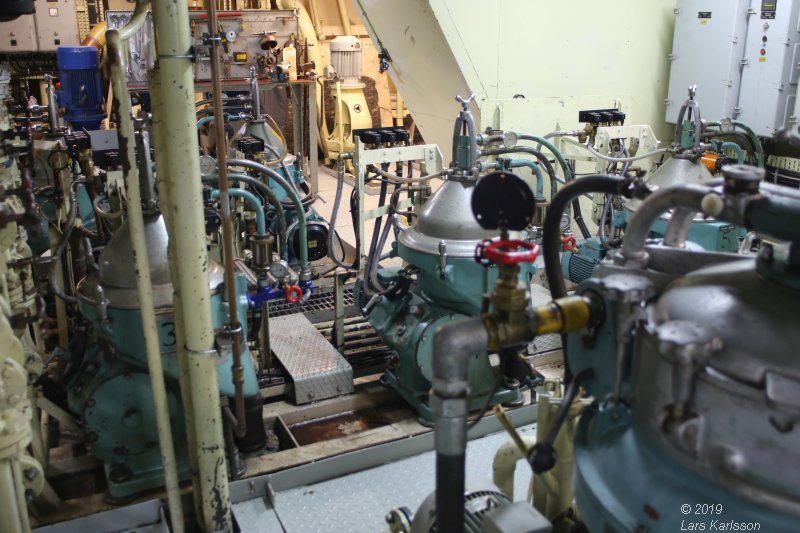

Tubes and pumps everywhere. About half the energy in the fuel is lost as heat, but some heat can be reused onboard. The others must be cooled by seawater.

The icebreaker has 1450 tons of fuel onboard and consume about 25 tons each day, much more when at heavy duty work.

One of five main engines, V12 diesel with compressor and water intercooler. Together they have 25000 hp and the electric generators can deliver 20000 hp to the electric motors, 5000 hp is lost, mostly as heat. Why not direct drive ? Because diesel electric power systems are much more easy to control which is important for an icebreaker.

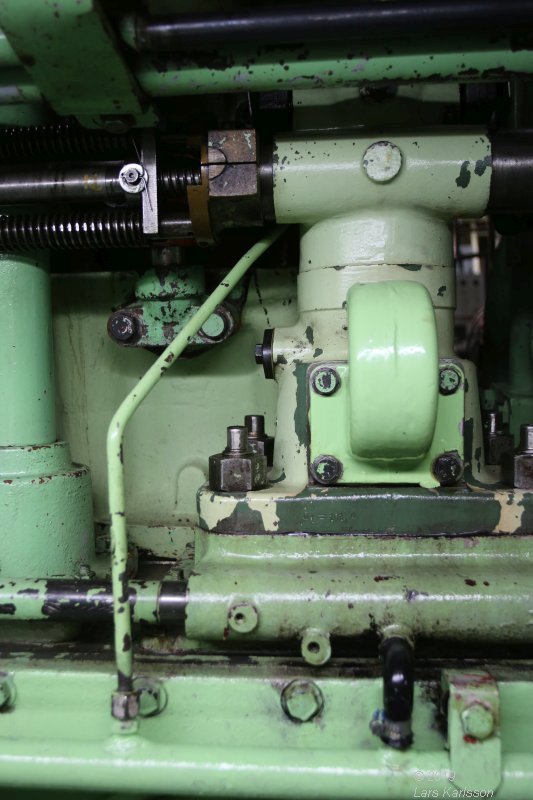

Diesel injection pump, one for each cylinder. The horizontal shaft above controls the amount of fuel injected to the cylinder.

The shaft that connect the engine to the generator. They remote control start and stop of the engines that shall running dependent of the load, from two to all five when heavy load. |

|

Top view of the five diesel engines, they are of four stroke construction. Look carefully and you see that the heads has 4 valves per cylinder. It's a bit strange to me that it's a four stroke engine, I thought all big diesel engines where two strokes.

4 help engines, 5000 hp together. Used to power the ships electric power system. The ship's consume 5000 kWh per day when anchored at harbor and connect to land power. When on duty it consumes much more.

Look at these wooden poles, something I learned at the marine how to use if the hull get broken. You stabilize the hull with them. The hull of the icebreaker is 32 mm thick.

Storm proof shutters for the windows.

Front anchor machinery, trust 11.5 tons. Each anchor weight 4.5 tons.

Two hours were spent on this tour, we could have spent more, very exiting! The END

|

| Go Back |