|

Advertisement / Annons: |

Chrysler Crossfire

|

|

OBD reader:In cars from about 1998 and later there is an OBD system, On Board Diagnostic. With that system you can communicate with the car's onboard computer. Very useful when there are malfunctions in the engine. Here are some information I have collected for you who want to know more: OBD information:If you want to know more about OBD-system analyze you have some information here:

If you choose to use an app as I do in your smartphone to read the data from an ODB adapter you can find more information here:

|

Where to find the OBD connector in a Chrysler Crossfire:In left hand drive cars you find the ODB connector below the dash on left side of steering wheel.

You have to crawl under the dash to find it.

Just behind the hood release you find the OBD connector. Always have the ignition turned off when connect and disconnect the OBD adapter. Check the profile of the connector to have it in correct orientation. What apps I use:I normally use the Torque Lite app.

Sometimes I use the app OBD Car Doctor:

There are a lot of others apps too, see the list above. It also depend of what kind of malfunction you have of your car when you decide which app is best to use. There are normally a free version of the apps so you can test if it works with your car. You can do much more with a hardware diagnostic tool, here is an overview special for Crossfire:

|

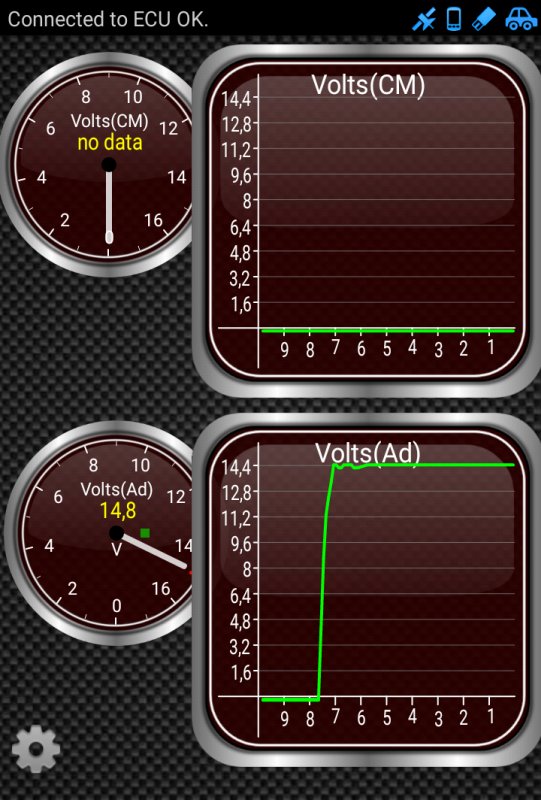

Examples of how I have used the OBD reader, Battery data:These screen dumps are from the Torque Lite app Android version.

Voltage from CM (Control Module) and Voltage Ad (Adapter data), there is no data from the CM module (inside the car) and no use of it. Maybe in the paid version.

In most OBD apps you can build your own windows. Here I have setup a configuration that show what I need when investigating what's wrong with the alternator. This is after I had replaced the alternator. Earlier it didn't charge correct and stayed at about 12 Volts. At the graph you see how the voltage started at 13 Volts, that was just after I had disconnected the battery charger. Then I start the engine and the voltage drops to 12.8 Volts. If it hasn't been charging by the battery charger just before it had dropped much more. When engine running the alternator charge the Voltage up to over 14 Volts.

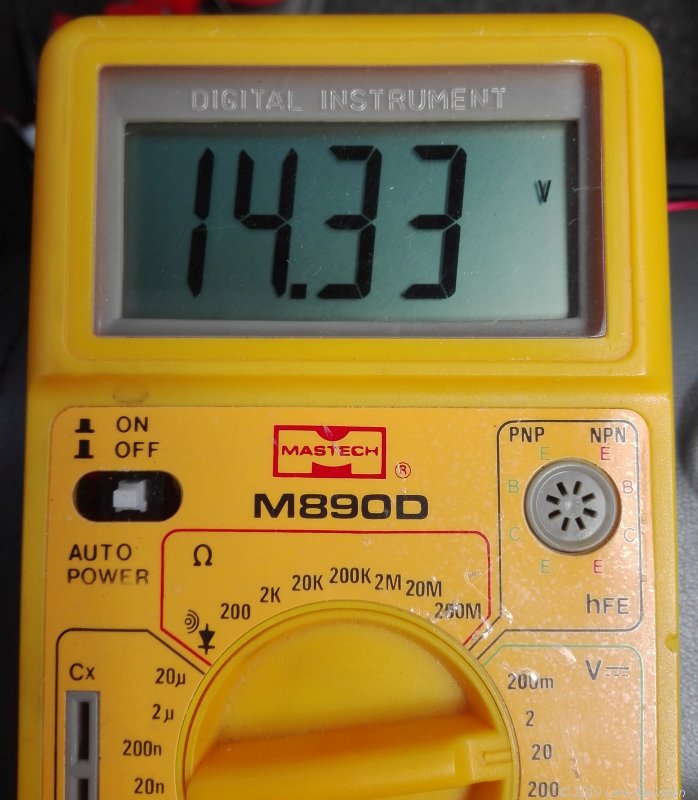

14.6 Volts is a bit high, a little bit more and it destroy the battery. I checked with my multi meter connected at the battery terminals, it display 14.3 Volts. Voltage from 13.9 to 14.3 is ok when driving the car and have some load on the battery, head lights, fan, radio etc. I have to subtract 0.3 Volts from the OBD data, I trust my multi meter more. More details how I replaced the alternator. |

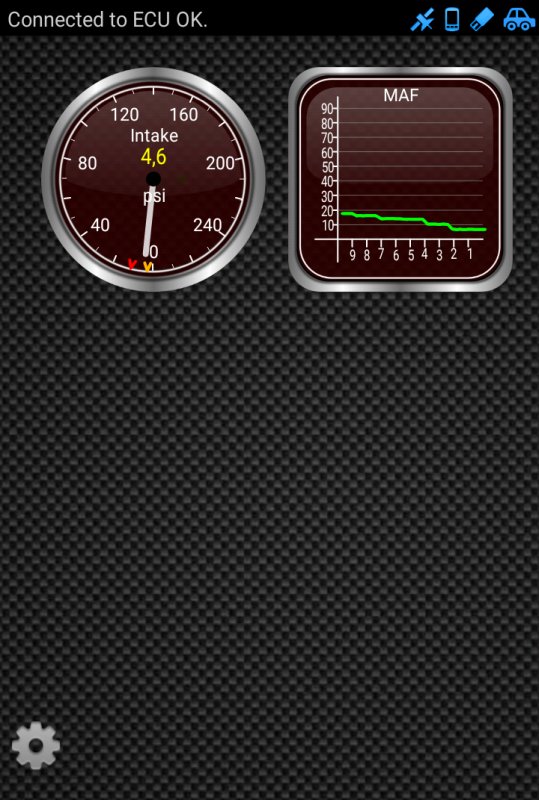

Examples of how I have used the OBD reader, checking engine data:These test are more when I was in a learning process how to use the OBD adapter and the apps.

From these instrument I have setup here I get information about:

Sometimes you maybe want to see its behavior over time. Then you can setup a graph, this is an example over how the MAF, Air mass flow varies over time. With all these engine data I got a good overview of the engine. |

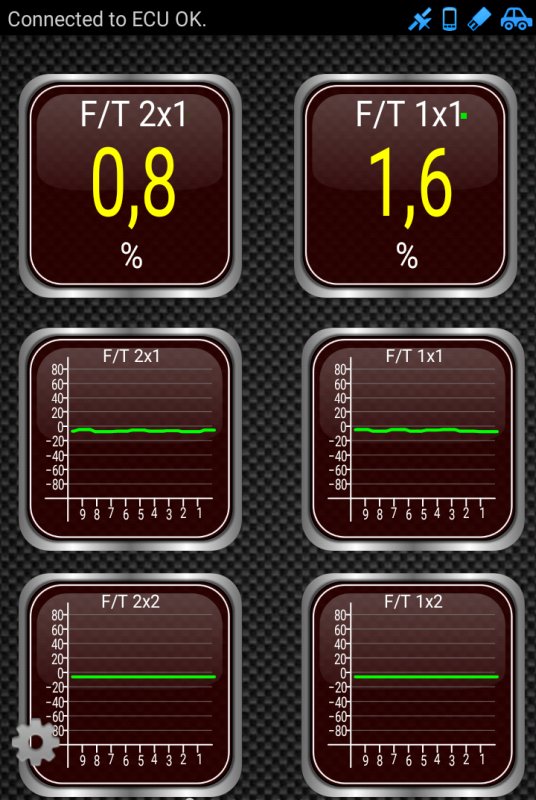

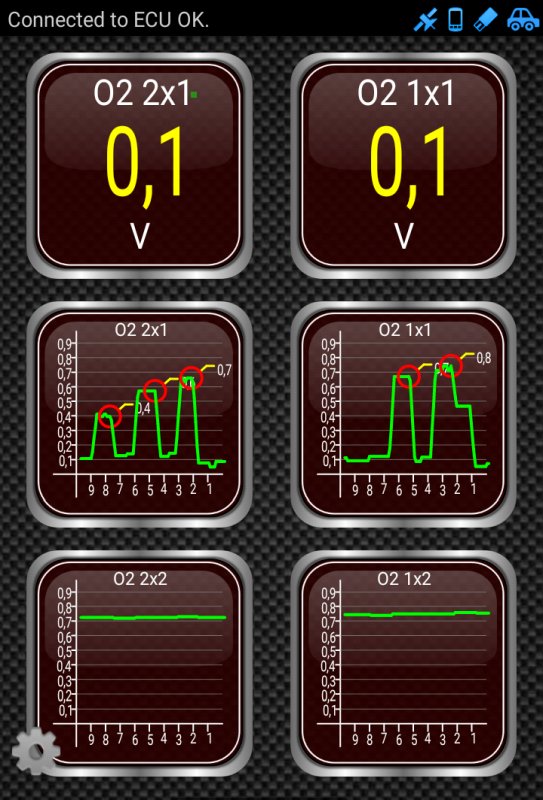

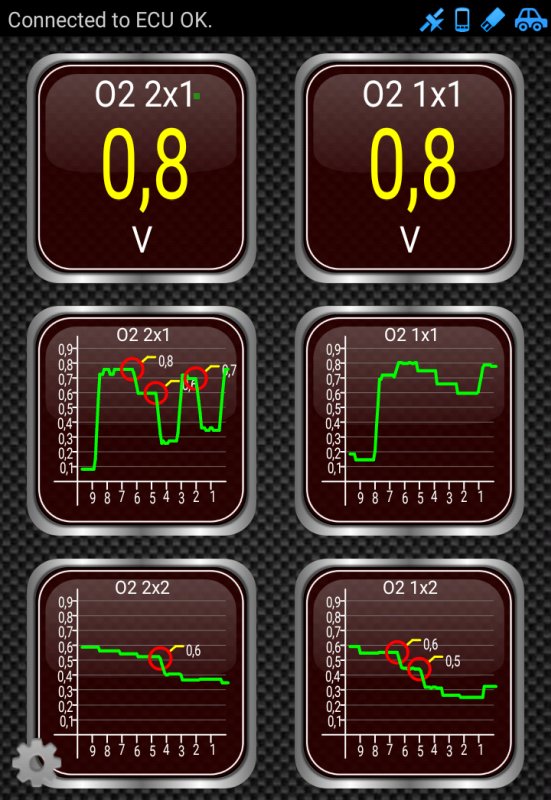

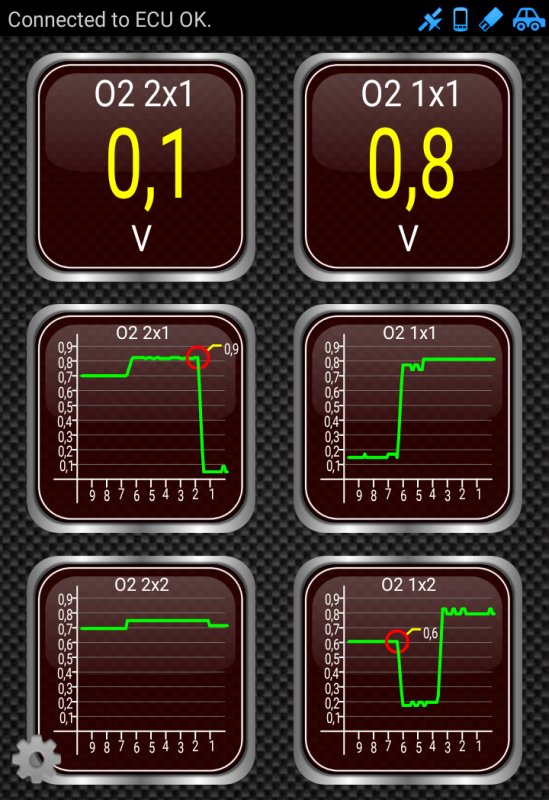

Examples of how I have used the OBD reader, checking engine's emission control:This is an example of what I used to solve the emission problem with the MIL lamp lit up. This problem was very difficult to solve and without these OBD data it had been an expensive workshop repair for me. Here are more information about my cars emission control malfunction. It could be several different problems that cause this emission problem. But the most common is that the O2 sensors (Lambda sensor) has to be replaced, they only have limited lifetime, about 100'000 kilometers. Modern engine with O2 sensors (Lambda sensor) use a computer to control the emission from the engine. If you have problem with this and get an engine alarm it could be very difficult to solve. These screen dumps are from the Torque Lite app Android version. All these examples are after I had repaired the emission control system.

These values help me a lot when doing repair of the O2 sensor emission regulation of the fuel injector.

F/T 2x1 = Fuel trim bank 2 upstream sensor (left side before catalyst)

These are the percent values, the small variation is hard to see in the graphs. You can also set it up for voltage which I used mostly.

The upstream O2 sensor are normally pulsating like this when the engine is running. From 0.1 to 0.9 Volts. The percent value which is the correction or fine trim data, should stay between +/- 5%. I feel the best setup is to have the display values in percent and the graph in voltage (not setup here).

More examples, I driving the car at 60 km/h speed and about 1500 rpm.

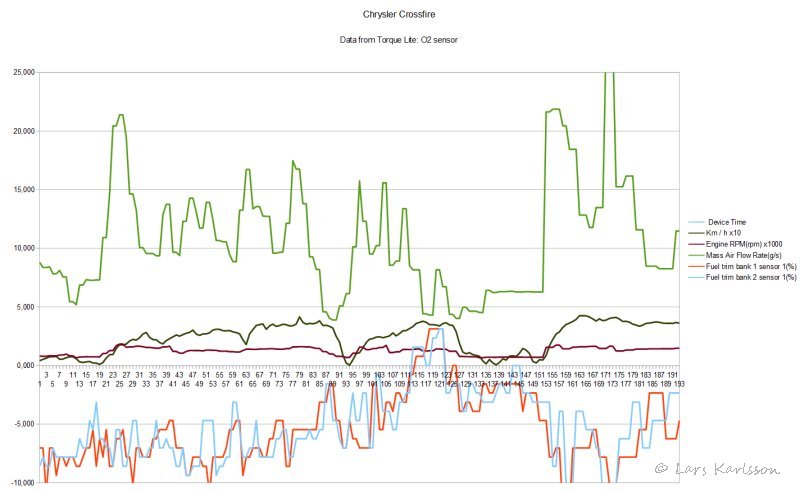

The downstream O2 sensor (bottom row) has waken to live, more a check function that the emission control system working ok. Logging data:I started a log of selected data (in the Torque Lite app) from the engine. Then I drive the car and stored the data in the smartphone. Later when home I transfer that data to my PC and put it in a Excel sheet and draw this graph from the data:  (click on the image to get a full resolution photo in a new window)

(click on the image to get a full resolution photo in a new window)

What you see here are the rpm, speed and air mass that flow into the engine and the Fuel trim from bank 1 and 2, the x-axis is time. When the engine has warmed up it goes into a closed loop, that's when the ECU box start to control the fuel against the emission. What it shows are the compensation in % of the default values (1 gram fuel to 14 gram air mass) it fine adjust the fuel / air ratio with. You see how the red and blue line regulate the fuel inlet after the signal from O2 sensors, speed and rpm of the engine. This is very good to know when you do a troubleshooting in your engine. Bank 1 and 2 are the row of cylinders on a V6 engine, bank 1 is were the cylinder number one is. Crossfire's V6 has bank 1 at the passenger side, steering wheel to the left. You can read in more detail here how I at last solved the O2 sensor problem. Without the OBD reader this emission control problem had been very difficult to solve.

|

| Go Back |