|

Advertisement / Annons: |

Chrysler Crossfire

|

|

1, Hub center rings with 10 mm spacer:With aftermarket wheels there are maybe a need of hub center rings to fill out the space between the hub and wheel bore. More to read about wheels, in this case, look at Center bore:

Other names I have seen for the rings are: hub center rings, hub center spigots rings. Sometimes when I mount my wheels on the car I can at higher speeds feel some vibrations. The wheels are correct balanced, could it be that the hub center rings are of wrong size ? I have aftermarket wheels on my car and a 10 mm spacer. The main function of the hub center ring is to center the wheel on the hub. It's in use only when you mount the wheel, after it is mounted the wheel bolts / nuts hold it in correct place (when plastic rings). With the car's original wheels it's normally not any need of these rings, the wheels center bore is already manufactured to fit the hub direct. With a incorrect sized or without a hub center ring the wheels can be off center and cause vibrations at high speed. In my case about 100 km/h. And because it could be different after I have remounted the wheels I suspect the hub center rings are of wrong size or defect. The wheel's inside bore diameter:

This is one of my hub center rings. I will now measure the size of it and check if it's correct. The outer diameter and the inner diameter.

Get rid of the dirt at the surfaces where the hub center ring connect to.

I already got in problem here, when I try to measure the diameter of the bore of the wheels I didn't have space enough for the caliper. Oh dear, how to solve that ?

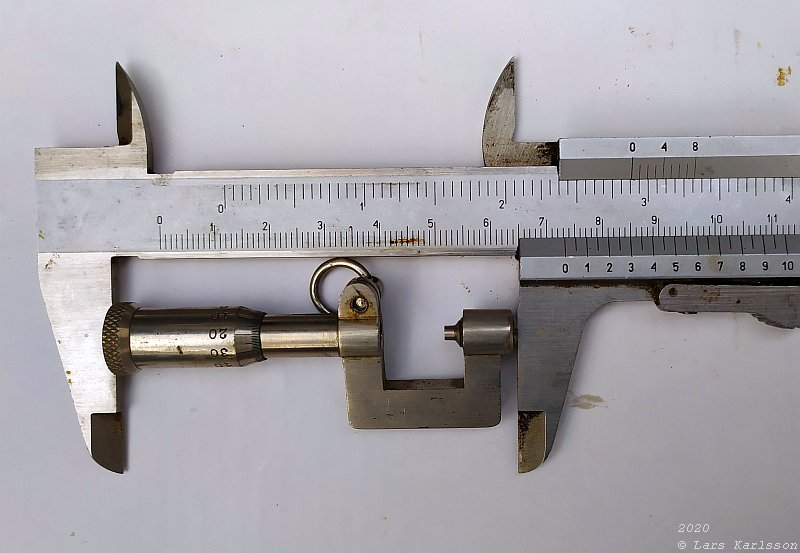

Instead I can measure the outside diameter of the hub center ring. But that will not give me the information of correct size I need to my wheels. The outer diameter is about 73.1 mm.

The hub center ring has a gap, that made it difficult to use the ring and get a correct size. Here you also see the 10 mm spacer I use. It fit on the original hub and extend with its own hub out to the wheel.

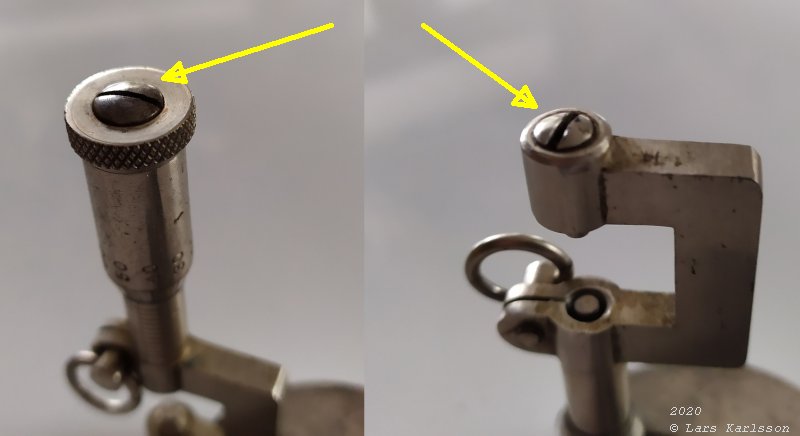

I must find another way to measure this with a higher precision. I consult my girlfriend, the girl with all the tools. Maybe she had something, I looked in her tool boxes but at first I couldn't find anything that I could used. But then I found a micro meter. Maybe I could use that tool. I use it backwards so to say. Even if it's not made to be used that way it will give me precision enough.

There are two screws at each end of the micro meter so it reach the inside of the rim at correct place. If the ends have been flat you had got incorrect measurement.

Now I can use the caliper tool and find the inner diameter to be 73.2 mm. Compare this with the hub center ring's 73.1 mm, a difference of 0.1 mm. That isn't very much, could that really caused me the problem with vibration sometimes. The spacer hub's outside diameter:

The hub outer diameter is much easier to measure, it is 66.6 mm, the Mercedes standard is 66.56 mm. This hub is on the 10 mm spacer, the car's own hub sits inside this spacer.

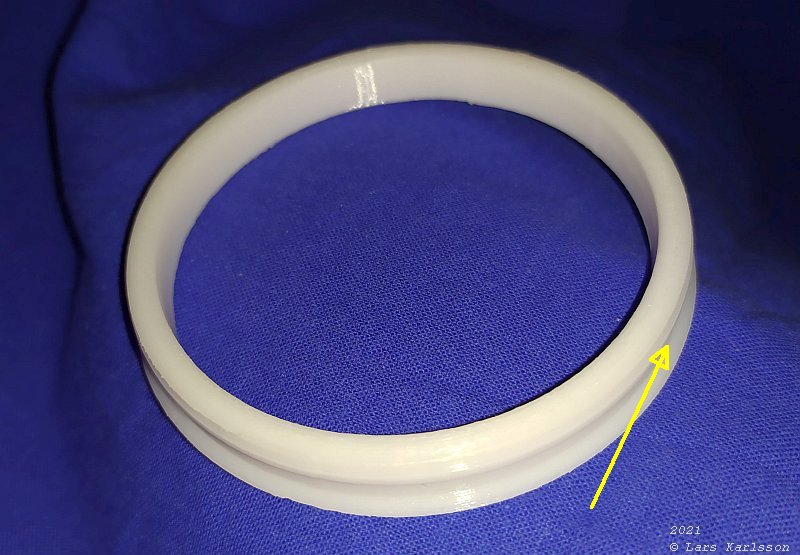

Conclusion: 3D printed hub rings:My order of the new hub rings failed to be delivered, I try to find another ones nearby. When Google about Hub rings I found some of them was told to be 3D printed.

I found drawings to print them on Thingiverse. I test printed one ring, this is just a test ring to see how it looks and fits. You have to setup the parameters for inner and outer diameter of your car's hub the the wheel bore. I can already see that this ring will not fit, but with some tweaking of the parameters in the setup file it should be possible to get it to fit. There are instructions on the Thingiverse page where you also download it. One important thing, the disc breaks can be hot, you must have a plastic quality that withstand this heat.

When I test mounted the hub ring on my new wheel it didn't fit, too big diameter.

|

|